Method for producing ferro-silicon by using a ferrous metasilicate electric stove integral deoxidation and reduction

A technology of ferrous silicate and electric furnace, which is applied in the field of producing ferrosilicon by the overall deoxidation and reduction of ferrous silicate electric furnace, which can solve the problems of comprehensive utilization and waste of resources, and reduce production costs, reduce production power consumption, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

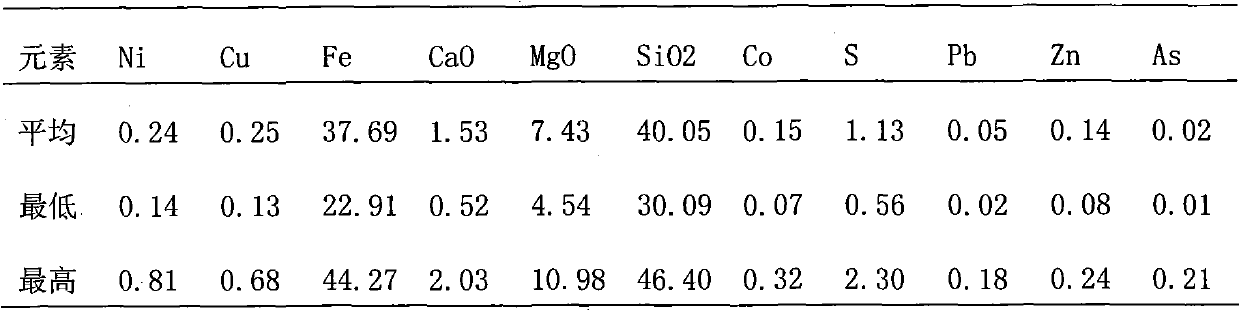

[0047] a. Heating nickel smelting waste slag to a molten state of 1150°C;

[0048] b. Place it in the hot slag bag and keep it warm at 1150°C. At the same time, extend the graphitized carbon material gas conduit into the bottom of the hot slag bag to feed oxygen (high pressure oxygen) into the nickel smelting waste slag. The amount of oxygen used is per ton of nickel smelting The waste residue is 0.4 cubic meters, and the oxygen flow is controlled at a uniform speed, and the ventilation time is 5 minutes;

[0049] c. Evenly and slightly shake the hot slag bag horizontally for 30 minutes, then let it stand for 8 minutes;

[0050] d. Remove the solid residue generated on the upper layer of the nickel smelting slag;

[0051] e. Cool the remaining part (mainly ferrous silicate), and then crush it to make balls of suitable size according to the existing ferrosilicon smelting requirements;

[0052] f. Then ferrous silicate pellets are used as iron raw materials together with silic...

Embodiment 2

[0054] a. Heating nickel smelting waste slag to a molten state of 1300°C;

[0055] b. Place it in the hot slag bag and keep it warm at 1300°C. At the same time, extend the graphitized carbon material gas conduit into the bottom of the hot slag bag to feed oxygen into the nickel smelting waste slag. The amount of oxygen used is 1 cubic meter per ton of nickel smelting waste slag. m, control the flow of oxygen at a constant speed, and the ventilation time is 10 minutes;

[0056] c. Evenly and slightly shake the hot slag bag horizontally for 40 minutes, then let it stand for 12 minutes;

[0057] All the other parts are identical with embodiment 1.

Embodiment 3

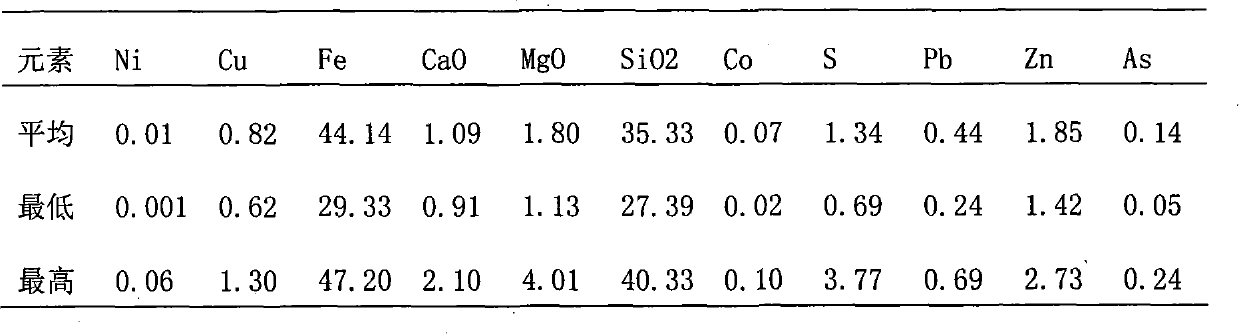

[0059] a. Heating copper smelting waste slag to a molten state of 1200°C;

[0060] b. Place it in the hot slag bag and keep it warm at 1200°C. At the same time, extend the graphitized carbon material gas conduit into the bottom of the hot slag bag to feed oxygen into the copper smelting waste slag. The amount of oxygen used is 0.8 cubic meters per ton of copper smelting waste slag m, control the flow of oxygen at a constant speed, and the ventilation time is 8 minutes;

[0061] c. Evenly and slightly shake the hot slag bag horizontally for 35 minutes, then let it stand for 10 minutes;

[0062] All the other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com