Method for constructing roadbed and base course by construction waste

A construction waste and road base technology, applied in buildings, roads, roads, etc., can solve problems such as high mud content research, achieve the effects of improving the environment, reducing maintenance costs, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

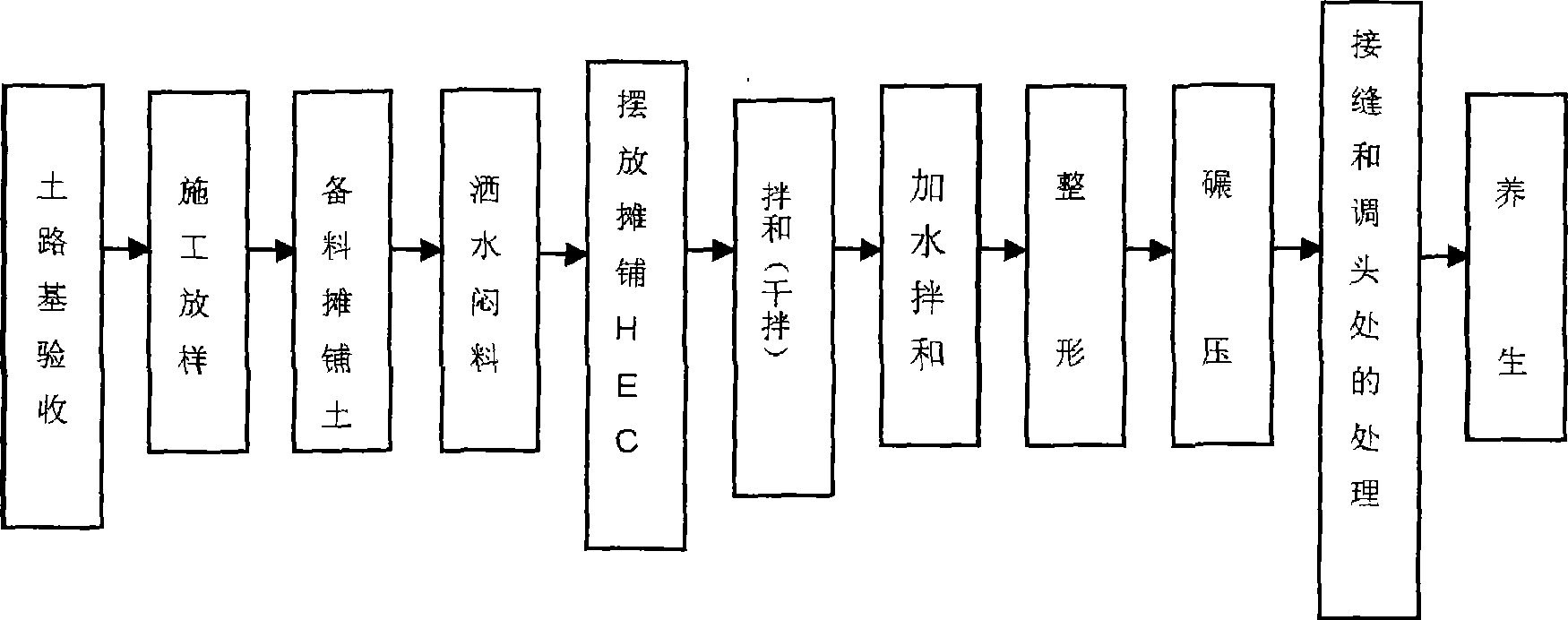

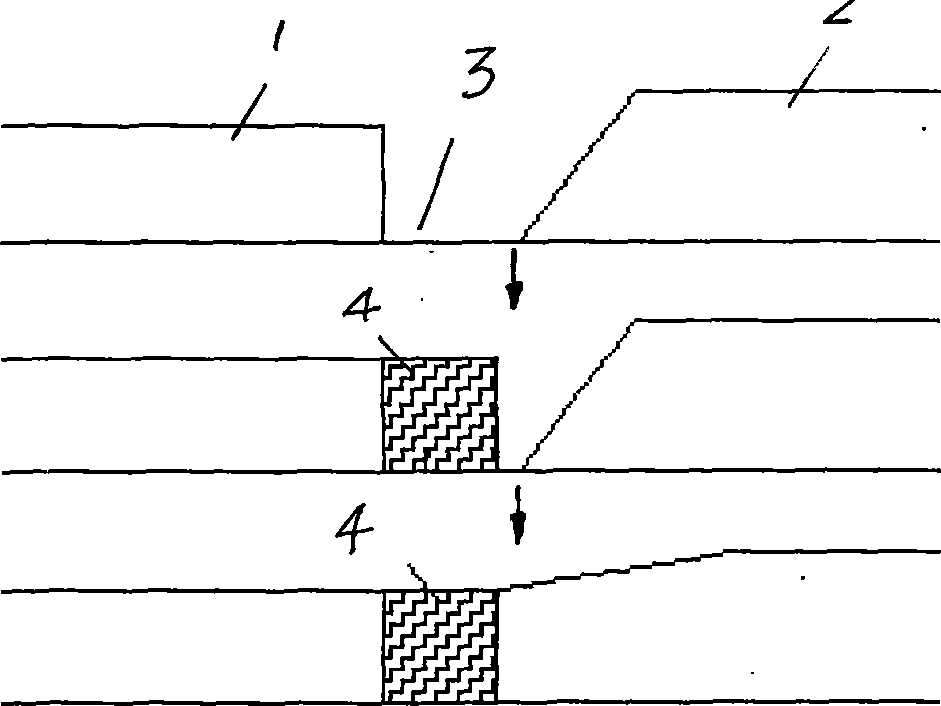

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

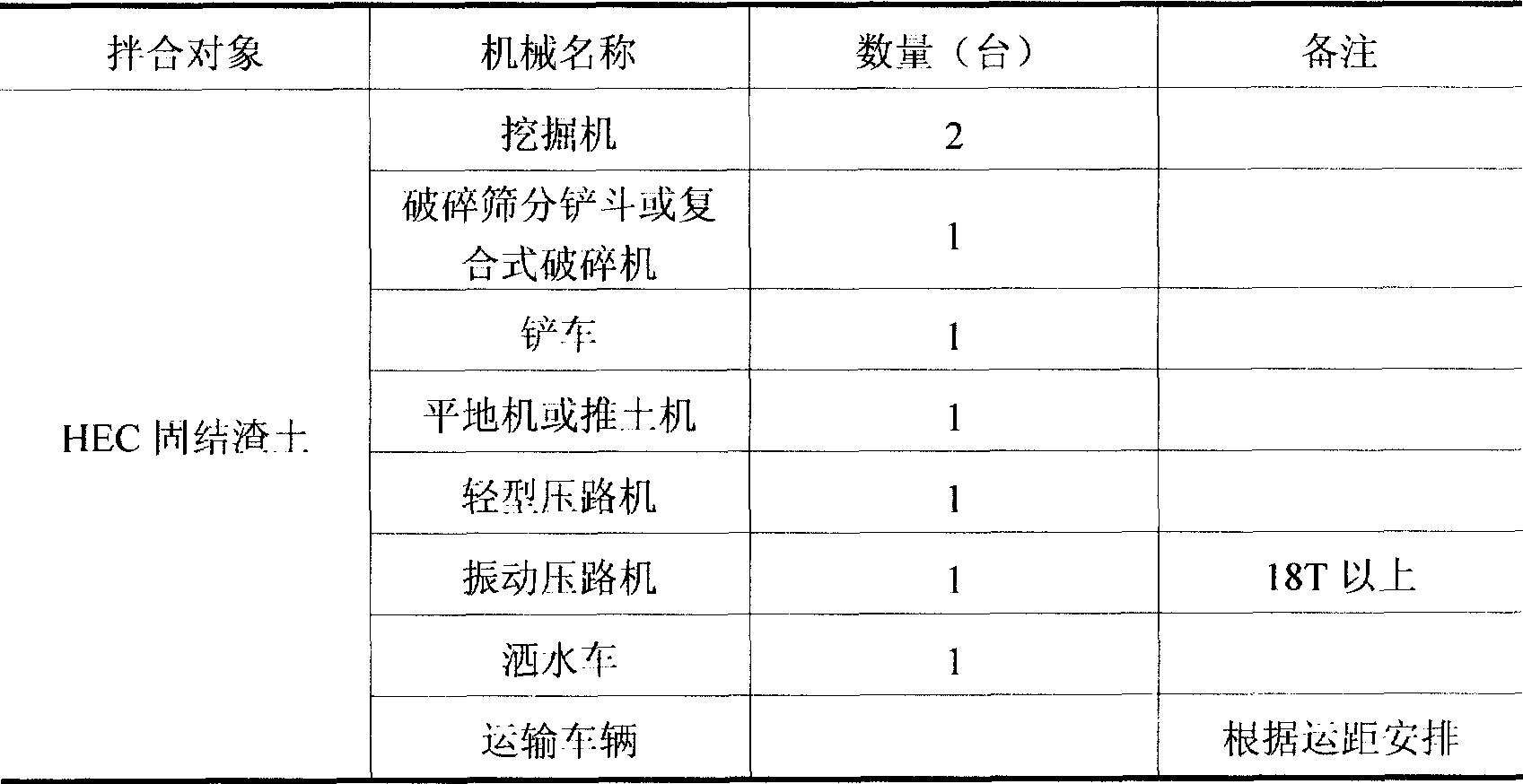

[0022] Construction waste refers to bricks, concrete blocks, sand and lime soil at the demolition site. However, construction waste contaminated by harmful impurities such as radioactivity, sulfate, heavy metals, and chloride salts shall not be recycled. The invention mainly crushes and screens waste bricks, waste concrete, brick soil and other mixtures contained in construction wastes on site, and then adds a consolidating agent to consolidate them and use them as road subgrades, subbases and base materials.

[0023] The present invention does not make specific requirements on the particle size, liquid and plasticity index of various soils in engineering application, and various cohesive soils, sandy soils, silty soils, sand, stone chips, stone powder, organic matter content below 8%. Gravel soil, gravel soil, excavation waste concrete powder, etc. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com