Composite transfusion pipe lined with fluorine resin or organic resin and producing method thereof

A technology of organic resin and manufacturing method, used in pipeline protection, mechanical equipment, pipeline protection through thermal insulation, etc., can solve problems such as products and process methods that are not involved, improve anti-waxing performance and corrosion resistance, and improve connection. Strength, the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

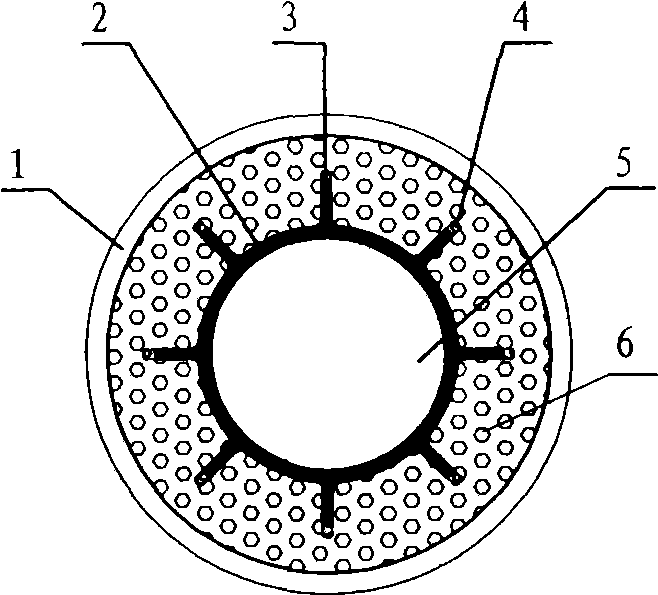

[0044] The cross-sectional structure diagram of the lined PP resin insulation oil pipeline is as follows figure 1 As shown, among them: 1 is the steel oil pipeline, 2 is the PP organic resin tube, 3 is the boss of the PP organic resin tube, 4 is the gap of the boss of the PP organic resin tube, 5 is the inner cavity of the PP organic resin tube, and 6 is the phase change reservoir. Energy-efficient polyurethane foam insulation material. The manufacturing process is as follows: put the PP organic resin tube into the inner cavity of the steel oil pipeline 1, fix the PP organic resin tube in the center of the steel oil pipeline 1 with a positioning plate with holes, and insert it into the gap between the steel oil pipeline 1 and the PP organic resin tube through the hole of the positioning plate. The polyurethane foam insulation material 6 containing the phase change energy storage material is poured, and the self-expanding polyurethane foam insulation material 6 containing the p...

Embodiment 2

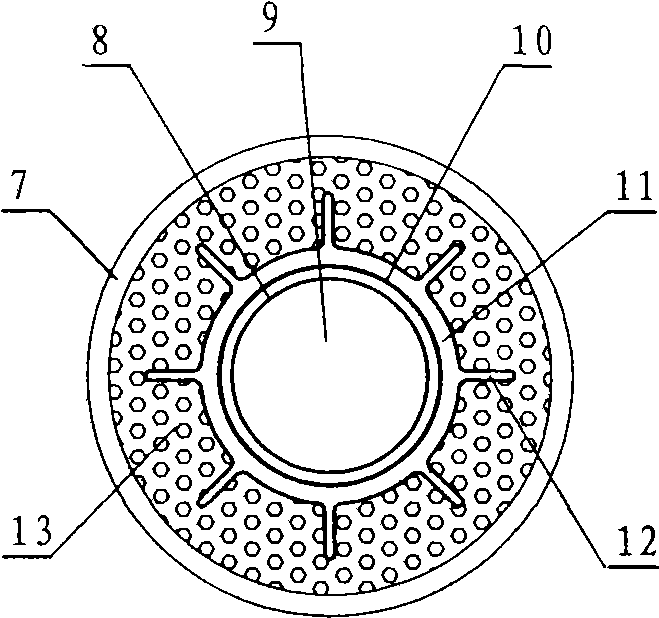

[0047] The cross-sectional structure diagram of the lined aluminum alloy composite fluororesin insulation oil pipeline is as follows figure 2 As shown, among them: 7 is steel oil delivery pipe, 8 is PTFE fluororesin tube, 9 is PTFE fluororesin tube oil delivery cavity, 10 is F-4D fluoroplastic adhesive, 11 is aluminum alloy tube, 12 is aluminum alloy tube wing, 13 is the polyurethane foam insulation material that contains phase change energy storage material. The manufacturing process is as follows: the inner layer of the aluminum alloy tube 11 is coated with F-4D fluoroplastic adhesive or the outer layer of the PTFE fluororesin tube 8 is coated with F-4D fluoroplastic adhesive 10, the PTFE fluororesin tube 8 is loaded into the aluminum alloy tube 11, and the aluminum alloy tube 11 and PTFE fluororesin tube 8 are closed at both ends, and the inner cavity of the PTFE fluororesin tube is closed to both ends. 9. The filling pressure is 1Mpa and the temperature is 120°C hot steam...

Embodiment 3

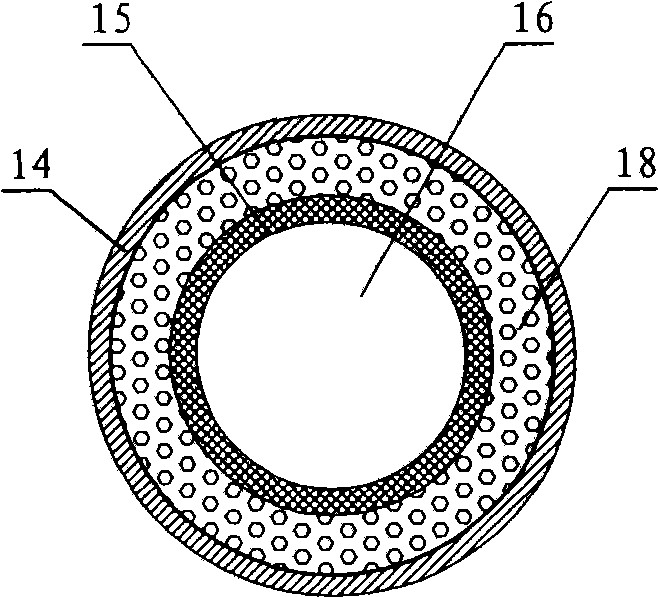

[0049] The cross-sectional structure diagram of the groove-lined fluororesin insulation oil pipeline is as follows image 3 as shown, Figure 4 yes image 3 Longitudinal section structure diagram, in which: 14 is the steel oil pipeline, 15 is the PTFE fluororesin tube, 16 is the inner cavity of the PTFE fluororesin tube, 17 is the groove of the PTFE fluororesin tube, 18 is the insulation material containing the phase change energy storage material, 19 is Rock wool fire ring. The manufacturing process is as follows: the outer surface of the PTFE fluororesin tube 15 is coated with glue, the PTFE fluororesin tube 15 with the groove 17 is put into the inner cavity of the steel oil delivery pipe 14, one end is blocked with a rock wool fireproof ring 19, and a positioning plate with a hole is used to seal it. Fix the PTFE fluororesin tube 15 at the center of the steel oil delivery pipe 14, fill the gap between the steel oil delivery tube 14 and the PTFE fluororesin tube 15 with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com