Method for manufacturing polarizing plates

A manufacturing method and technology of polarizing plates, which are applied in optics, polarizing elements, nonlinear optics, etc., can solve problems affecting the degree of polarization of polarizing plates, large molecular structure, and poor iodine dichroism, and reduce light leakage in dark states , increase the effect of contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

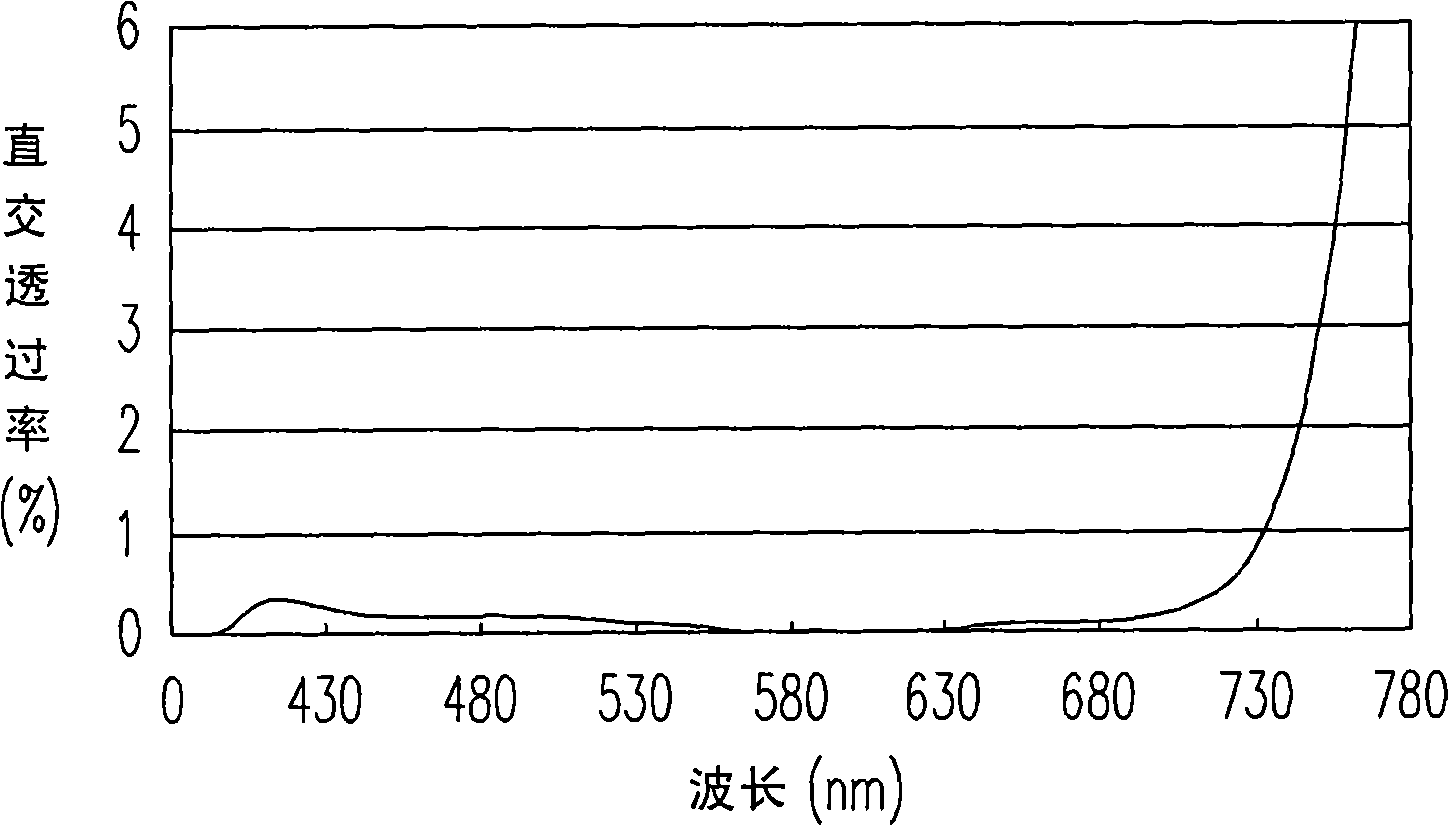

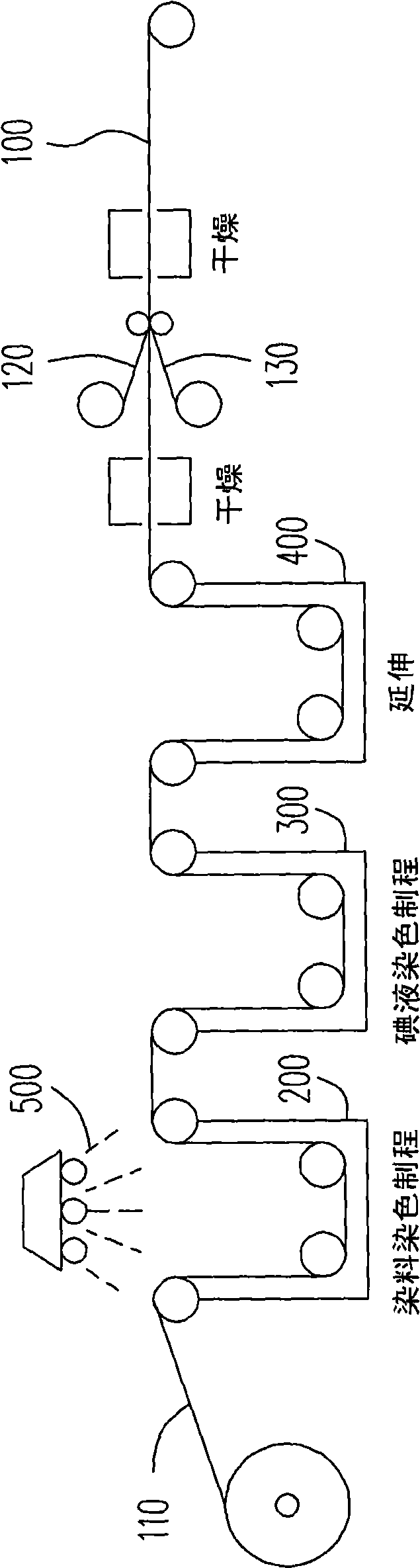

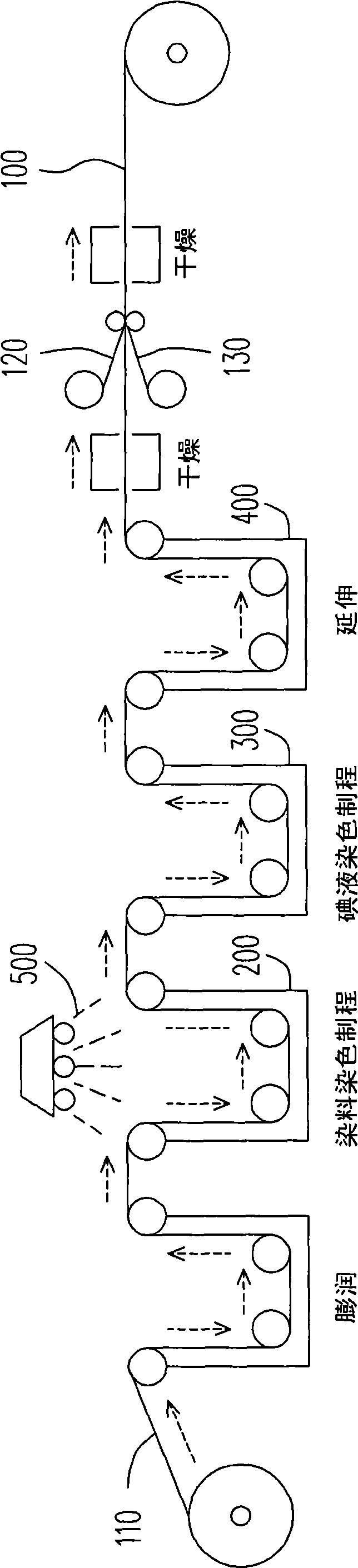

[0028] figure 2 It is a schematic diagram of a manufacturing process of a polarizing plate according to a first embodiment of the present invention. The manufacturing method of the polarizing plate of the present invention mainly combines the dyeing process and the iodine solution dyeing process, so that the manufactured polarizing plate has the advantages of good weather resistance of the dye-based polarizing plate and high polarization degree of the iodine-based polarizing plate. Please refer to figure 2 As shown, firstly, a polyvinyl alcohol (PVA) film 110 is provided, and the polyvinyl alcohol film 110 is transported between different workstations by using a plurality of rollers. Afterwards, the polyvinyl alcohol film 110 will be transported into a first dyeing tank 200 to perform a dyeing process on the polyvinyl alcohol film 110 . Furthermore, when the polyvinyl alcohol film 110 is dyed with dye, the present invention utilizes an ultraviolet light 500 to irradiate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com