Negative-working radiation-sensitive compositions and imageable materials

A composition and sensitive technology, applied in the application of radiation from radioactive sources, instruments, lithography equipment, etc., can solve the problems of digital speed loss, etc., and achieve the effect of good printability, high imaging sensitivity, and good shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

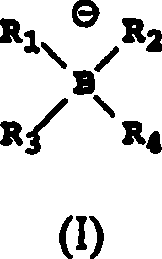

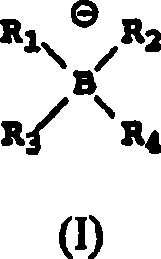

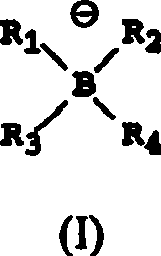

[0055] Accordingly, a number of initiator / co-initiator combinations can be used in various embodiments of the invention, namely:

[0056] a) the combination of the above-mentioned triazine and the above-mentioned co-initiator, which is the above-mentioned N-aryl, S-aryl or O-aryl polycarboxylic acid with at least two carboxyl groups, wherein at least one carboxyl group is bonded to On the nitrogen, oxygen or sulfur atoms of the aryl units (for example anilinodiacetic acid and its derivatives and other co-initiators),

[0057] b) a combination of the aforementioned triazines and co-initiators that are derivatives of the aforementioned thiols,

[0058] c) a combination of an iodonium salt as described above (e.g. iodonium borate) and a co-initiator that is a metallocene (e.g. titanocene or ferrocene) such as described above in US Pat. No. 6,936,384 (noted above), and

[0059] d) Combinations of iodonium salts as described above (eg iodonium borates) and co-initiators that are m...

Embodiment 1

[0174] Synthesis Example 1: Preparation of monomer A, tetraphenylboronic acid [3-(methacrylamido) propyl] trimethylammonium

[0175] In a 500 ml beaker labeled Container A, sodium tetraphenylborate (13.68 g, Aldrich Chemical Co.) was dissolved in 300 g of water. In a 1000 ml beaker labeled Vessel B, [3-(methacrylamido)propyl]trimethylammonium chloride (17.64 g, 50% in water, Aldrich Chemical Co.) was diluted in 500 g of water. The solution in vessel A was slowly (over approximately 10 minutes) added to the solution in vessel B while stirring vigorously by a Silverson L4R. A white precipitate formed and the mixture was stored in the refrigerator for 2 hours. After the first filtration, the white solid was collected and washed with 100 ml of water. The product was obtained from the second filtration and dried at ambient temperature over the weekend, then in an oven at 35°C for 4 hours to afford 20 g of a white solid.

Embodiment 2

[0176] Synthesis Example 2: Preparation of Polymer A

[0177] AIBN (1.6 g), methyl methacrylate (20 g), acrylonitrile (24 g), vinyl carbazole (18 g, from Polymer Dajac), methacrylic acid (18 g) and DMAC (320 g) were placed in a Magnetic stirring, temperature controller and N 2 Inlet in a 1000ml 3-neck flask. The mixture was heated to 60 °C under N 2 Stir under protection overnight (approximately 16 hours). The % non-volatiles were measured to be approximately 20%. The nitrogen blanket was removed and 5.2 g KOH in 40 g water was added. A viscous liquid formed. After stirring the mixture for 10 minutes, 13.3 g of allyl bromide was added and the mixture was stirred at 55° C. for 3 hours. A 36% HCl solution (12 g) in 40 g DMAC was added to the flask and stirred for an additional 3 hours. The reaction mixture was filtered to remove inorganic salts formed. This filtrate was then slowly dropped into a mixture of 12 liters of water and 20 g of 36% HCl solution while stirring. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com