Flower pot and method of preparing the same

A technology of flower pots and pots, which is applied in botany equipment and methods, other household utensils, special decorative structures, etc., can solve the problems of low grade, monotonous colors and varieties, and poor gloss, and achieve convenient transportation and use, High-grade product, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

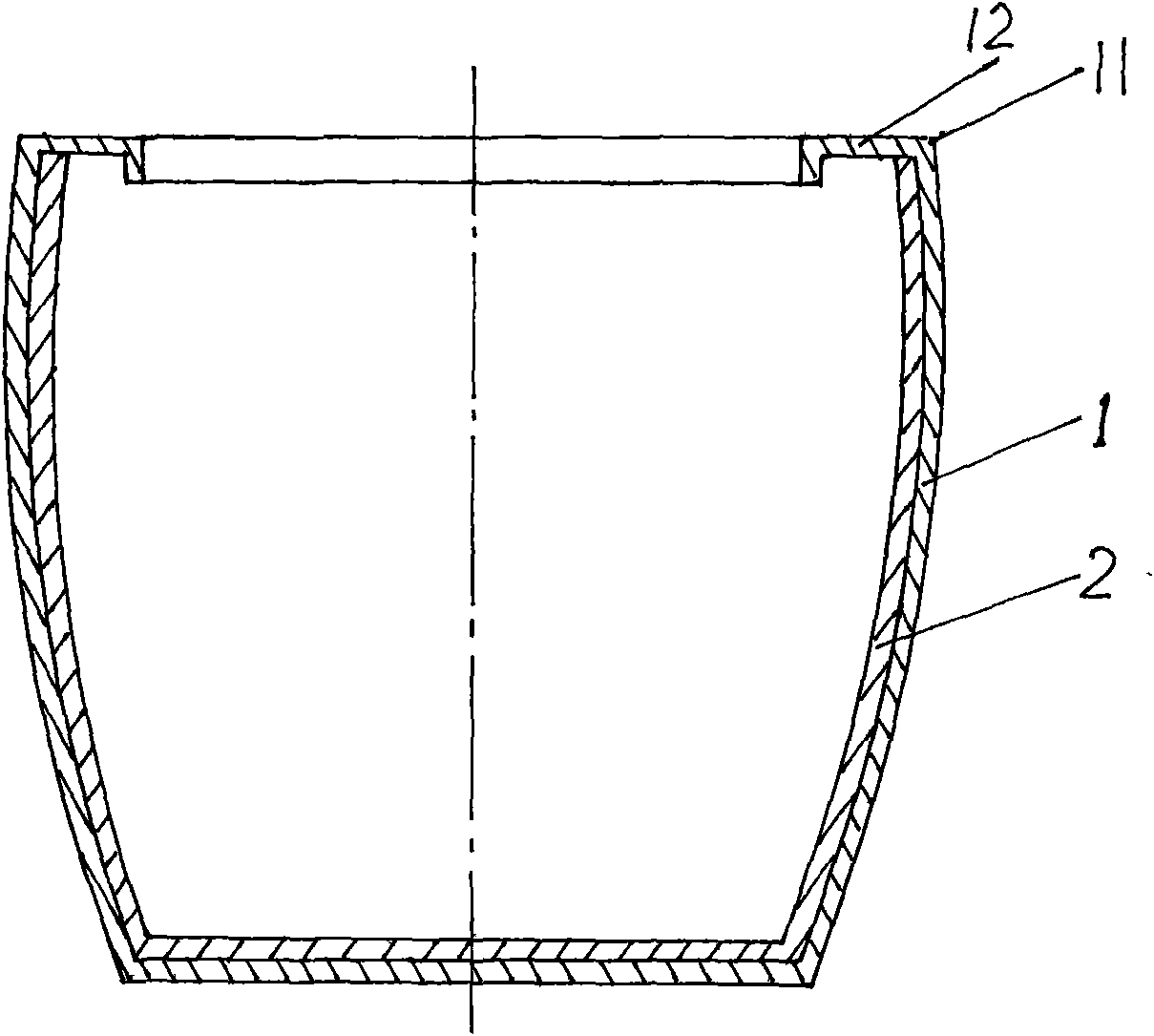

[0020] Such as figure 1 As shown, it includes a circular basin body 1. The basin body 1 is formed by pressing a cast acrylic plate. The basin mouth 11 is bent inward and extended to a certain width to form a basin edge 12; Reinforcement layer 2, the strength reinforcement layer 2 is formed by mixing glass fiber and unsaturated resin.

[0021] The preparation method of above-mentioned flower pot, its processing step comprises:

[0022] (1) Heat the cast acrylic plate in an oven to 180-190°C;

[0023] (2) Make a mold according to the shape of the flower pot, and suck it into the shape of the pot body 1 with a vacuum pump;

[0024] (3) Mix glass fiber and unsaturated resin in a ratio of 1:2, apply it on the inner side of the basin body 1 to form a strength strengthening layer 2, and naturally solidify at room temperature.

Embodiment 2

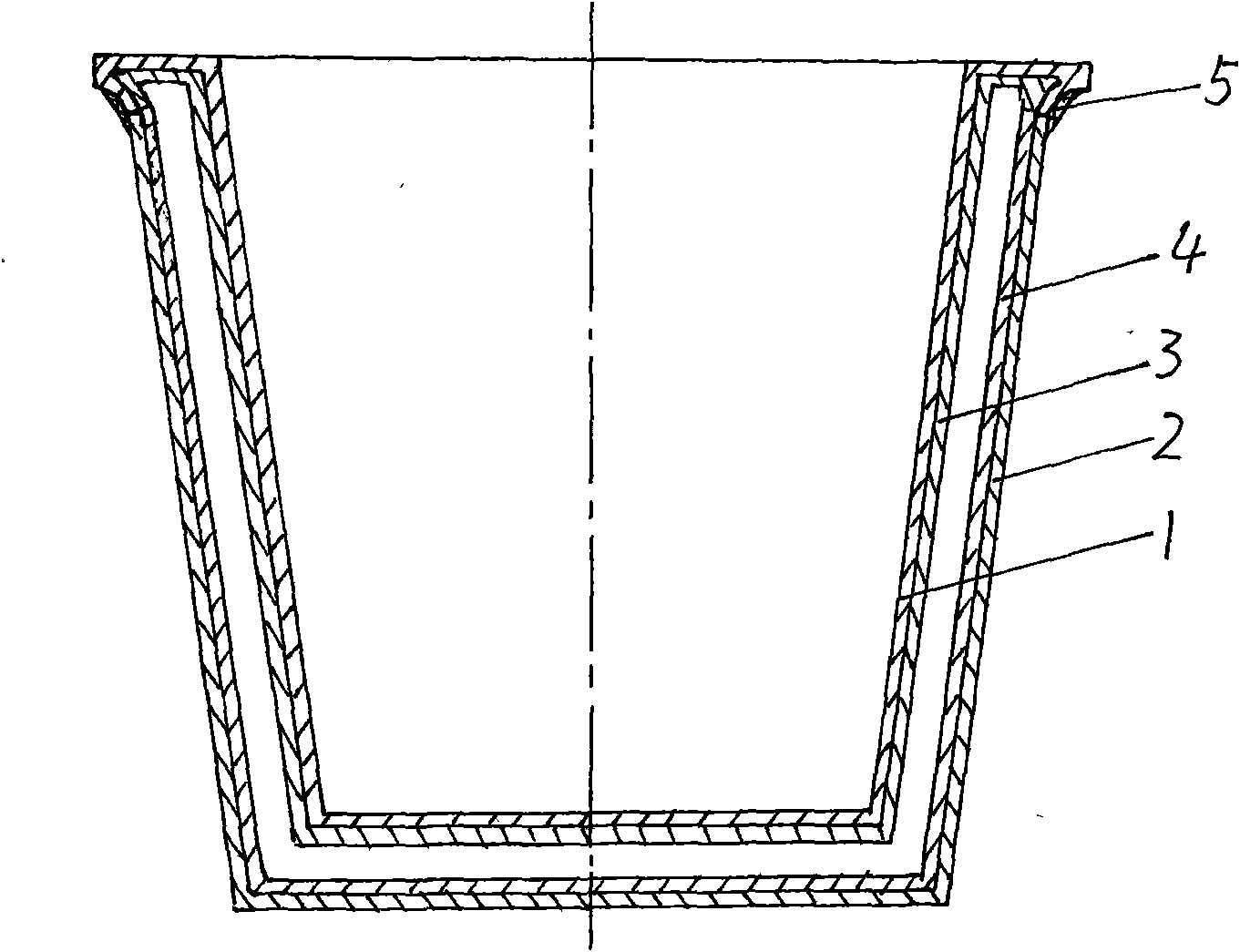

[0026] Such as figure 2 As shown, it includes a square basin body. The square basin body is composed of an inner layer 1 and an outer layer 2. The inner layer 1 and the outer layer 2 of the basin are formed by pressing a cast acrylic plate. The outer side of the inner layer 1 is coated with a strength reinforcing layer 4 and 3, which are made of glass fiber and unsaturated resin; the interface between the inner layer 1 and the outer layer 2 is glued with an adhesive combine.

[0027] The preparation method of above-mentioned flower pot, its processing step comprises:

[0028] (1) Heat the cast acrylic plate in an oven to 180-190°C;

[0029] (2) Make basin inner layer and outer layer mould, suck into the shape of basin inner layer 1 and outer layer 2 respectively with vacuum pump;

[0030] (3) Mix glass fiber and unsaturated resin in a ratio of 1:2, apply it on the inner side of the basin outer layer 2 and the outer side of the inner layer 1 to form strength strengthening l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap