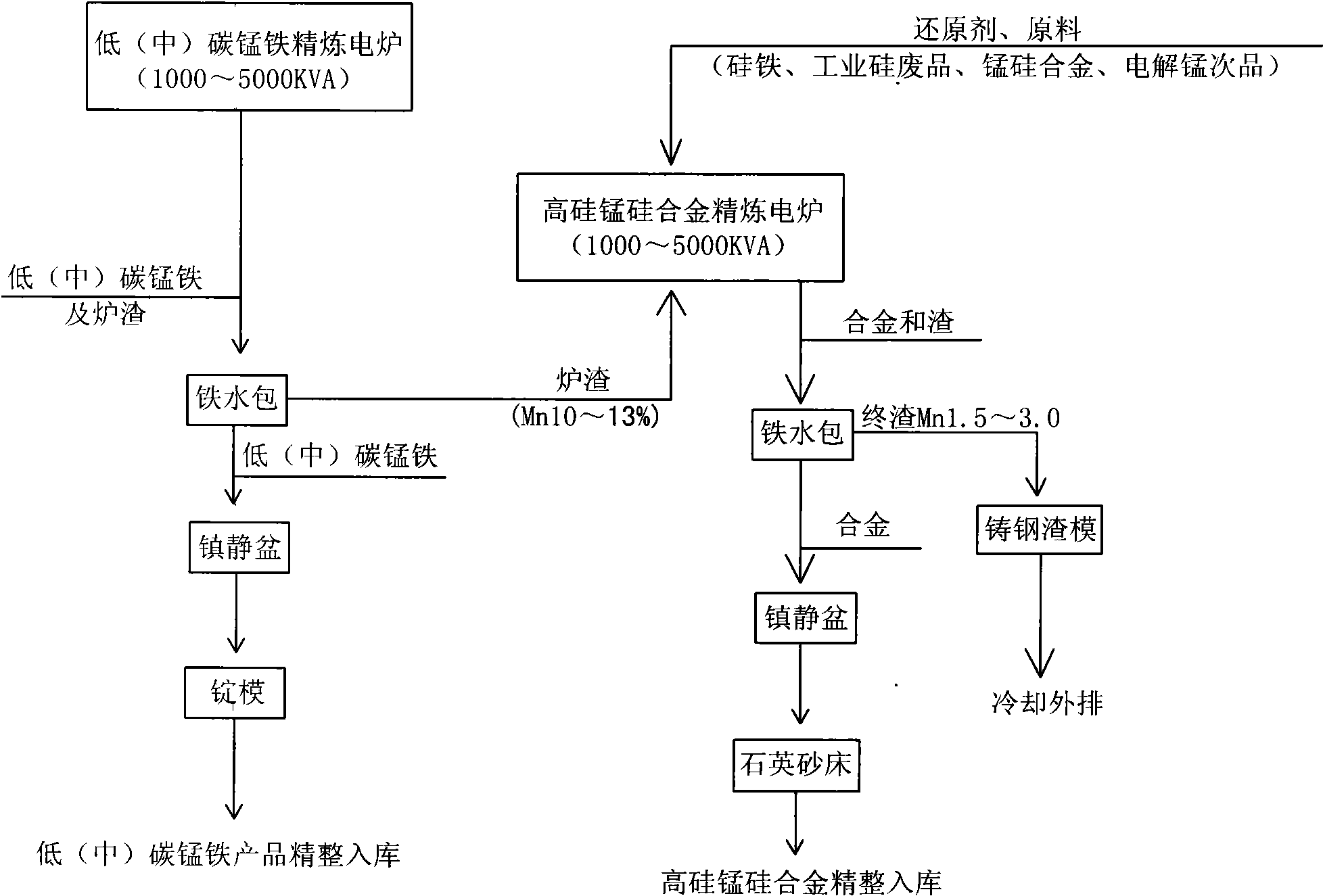

Process for producing high silicon manganese-silicon alloy by using electric refining furnaces

A manganese-silicon alloy and high-silicon technology, which is applied in the process of producing high-silicon-manganese-silicon alloys with refining electric furnaces, can solve the problems of rising costs of high-silicon-manganese-silicon alloys, affecting cost increases, etc., achieving significant energy-saving effect and occupying less equipment. , the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The smelting equipment, process operation, product variety adjustment and quality control required by the present invention.

[0032] 1. Smelting equipment

[0033] Implementing the present invention requires two refining electric furnaces, one refining electric furnace produces low (middle) carbon ferromanganese, and the other refining electric furnace produces high silicon manganese silicon alloy. In this way, hot charging of high-temperature liquid low (medium) carbon ferromanganese slag into the high-silicon-manganese-silicon alloy refining electric furnace can be realized. Electric furnaces are built with magnesia materials. The power of the electric furnace is 1000-5000KVA, and the optimal capacity is 2000-3500KVA. The molten iron ladle used in the electric furnace has the same volume, and its size is required to hold a furnace of molten iron and slag. The ladle is built with magnesia bricks. The pouring equipment used in the electric furnace is also basically ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap