Petal pore plate longitudinal-flow heat exchanger

A technology of heat exchanger and orifice plate, which is applied in the direction of heat exchanger type, indirect heat exchanger, heat transfer modification, etc. It can solve the problem of fluid flow performance that needs to be improved, heat transfer efficiency of heat exchanger is reduced, and flow resistance is increased and other problems, to achieve good anti-scaling and descaling functions, convenient processing, good anti-vibration and anti-vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

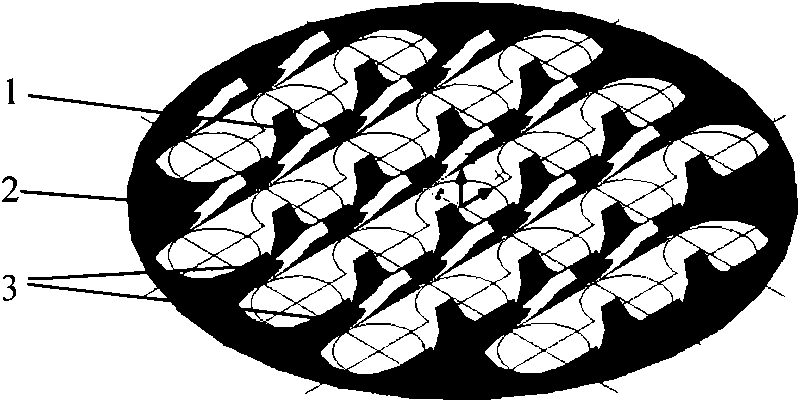

[0007] The structural processing of the petal orifice plate is still based on the full circular plate. After the tube holes are drilled, the hole bridge between the adjacent tubes is cut along the same direction and punched to one side to form a petal shape, so that the fluid between the tubes is longitudinal. Flow and wash the petals on the support strips of the orifice plates. During installation, the two petal orifice plates are arranged in a criss-cross pattern, and the support strips on the two orifice plates are used to realize all-round constraints on the heat exchange tubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com