Multi-purpose diplopore siamesed magnetic core

A multi-purpose, conjoined technology, applied in the direction of magnetic core/yoke, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of low electromagnetic conversion efficiency, unsuitable for energy saving and consumption reduction, and large core loss, etc. Achieve the effect of improving electromagnetic conversion efficiency, simple adjustment of electrical parameters, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

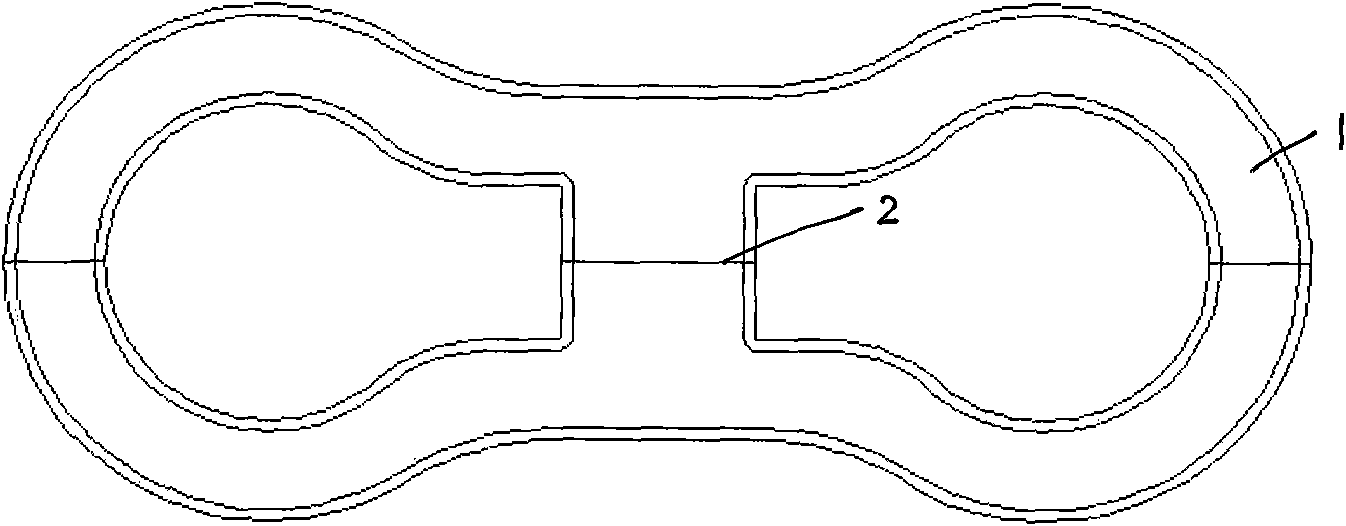

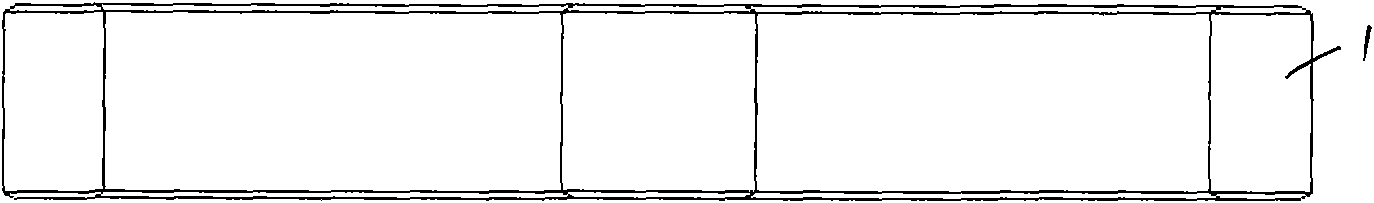

[0012] Such as Figure 1-2 As shown, the multi-purpose double-hole conjoined magnetic core is a split-combined double-hole conjoined magnetic core. Two "3"-shaped magnetic cores 1 are relatively assembled to form a whole "8"-shaped closed special-shaped magnetic core. Its cross section is substantially rectangular. The two "3" middle columns protrude in the form of right-angled vertical columns, which is convenient for winding the coil bobbin.

[0013] There may be air gap or no air gap at the closing part 2 of the two "3" middle columns, and it can be made of various soft magnetic materials, such as commonly used manganese zinc or nickel zinc ferrite, permalloy or silicon steel sheet, etc. The two "3" are completely symmetrical, forming a completely closed magnetic circuit. The circular transition is shorter than the E-shaped magnetic circuit and saves material. The transformer made of the frame covered with the center column and the electromagnetic induction coil wound on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com