Semiconductor package structure having movable gain variation on circumsphere point

A technology of gain change and circumscribed ball, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as fracture and ball drop, substrate warping, prone to overflowing or climbing glue, etc., to achieve The effect of reducing stress and avoiding fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

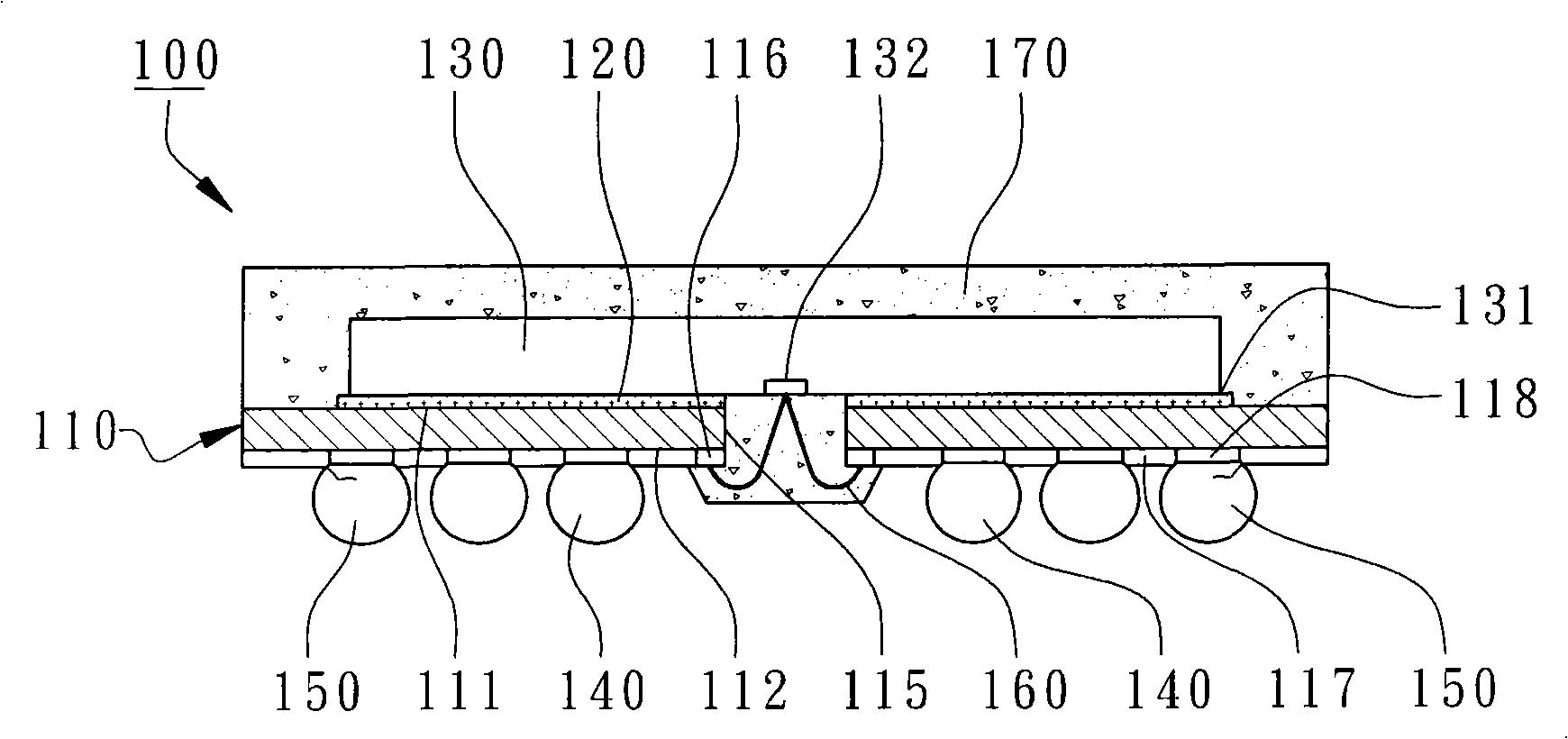

[0073] According to the first embodiment of the present invention, it discloses a semiconductor package structure with a circumscribed ball having movable gain variation.

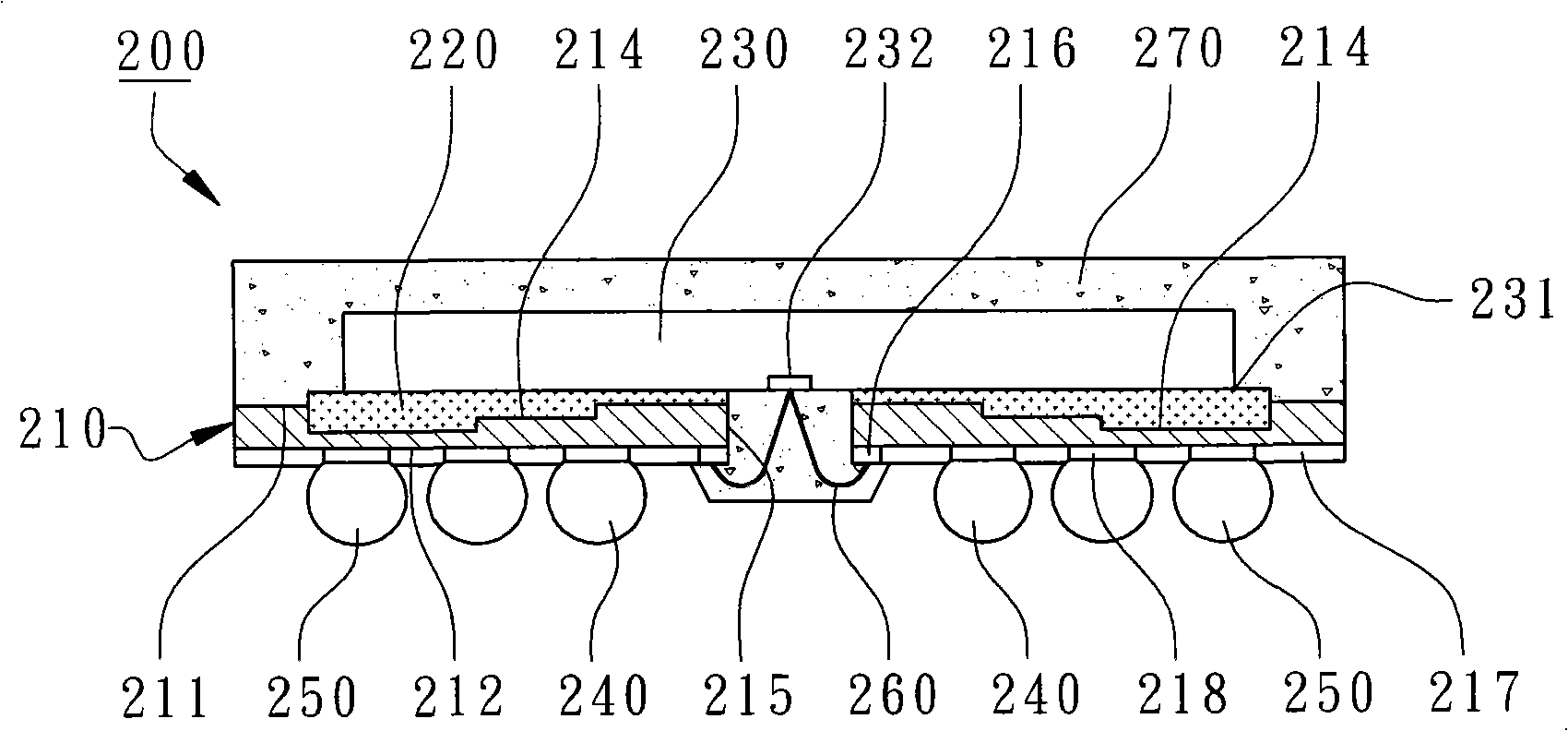

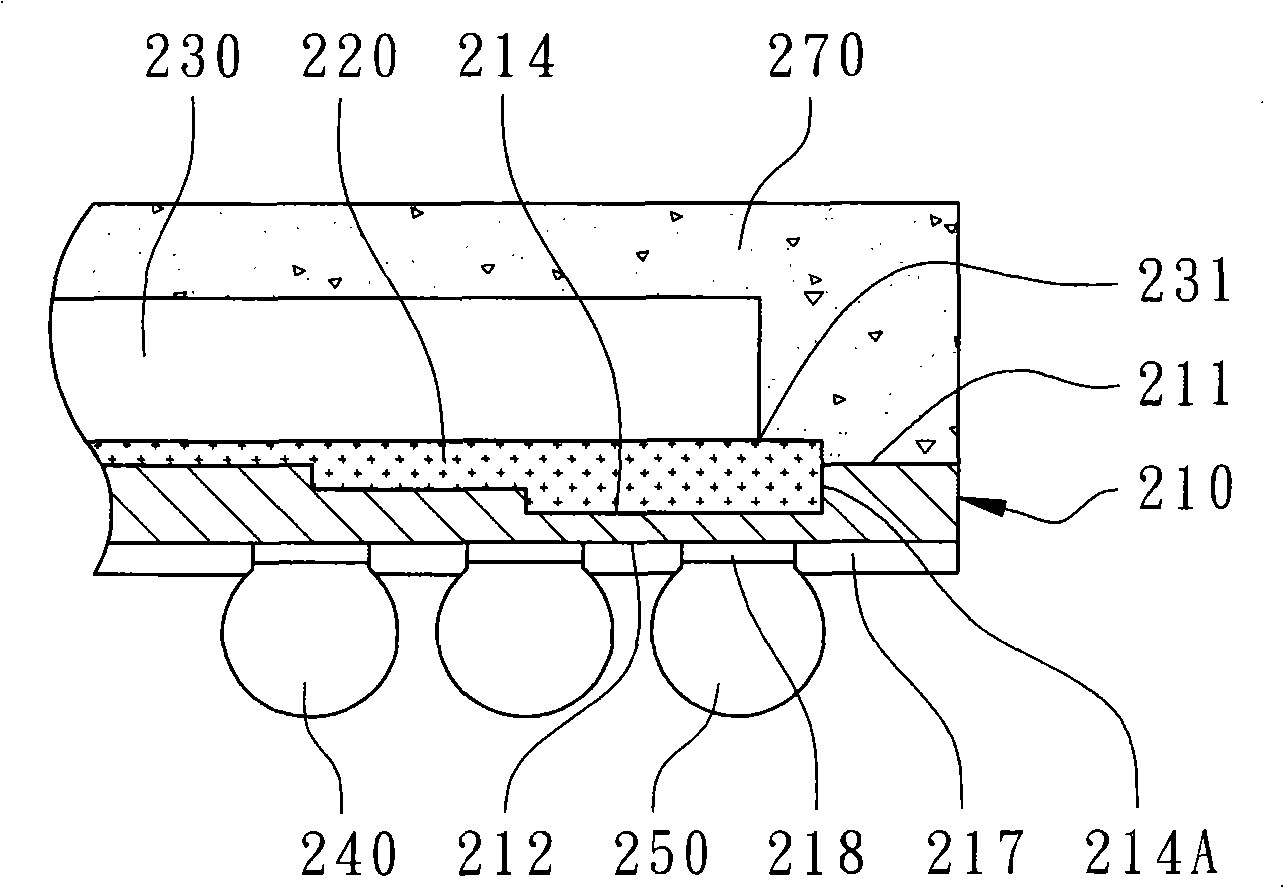

[0074] Such as figure 2 and image 3 As shown, the semiconductor package structure 200 mainly includes a substrate 210 , a die-bonding adhesive 220 , a chip 230 , two or more first rows of outer balls 240 and two or more second rows of outer balls 250 .

[0075] The substrate 210 has a package surface 211, an exposed surface 212 and a through hole 215, wherein the package surface 211 includes a die bonding area 213, such as Figure 4 As shown, the size of the die attach 213 may be approximately equal to the size of the chip 230 .

[0076] Wherein, these second rows of external ball points 250 are linearly arranged in a manner parallel to the center line of the die bonding area 213, and these second row of external ball points 250 are farther away from the center line relative to these first row of extern...

no. 2 Embodiment

[0088] The second specific embodiment of the present invention discloses another semiconductor package structure with a movable gain change at the external ball point, which can use a back-to-back double-chip stacked window ball grid array package product (back-to-back DDP WBGA), mainly The components are substantially the same as those of the first embodiment, so the same reference numerals are used, see Figure 6 As shown, for example, a substrate 210 , a die-bonding adhesive 220 , a first chip 230 , a first row of outer ball pads 240 and a second row of outer ball pads 250 . The semiconductor package structure may further include a second chip 280 stacked on the backside of the chip 230 back to back. But without limitation, more chips can be stacked on top, such as three, four or more, to form a multi-chip stacked package structure, which can improve operating efficiency. Specifically, the active surface of the second chip 280 has two or more second bonding pads 281, and c...

no. 3 Embodiment

[0090] The third embodiment of the present invention discloses another semiconductor package structure in which the circumscribing ball has movable gain variation. see Figure 7 As shown, the semiconductor package structure 300 mainly includes a substrate 310 , a die-bonding adhesive 320 , a chip 330 , two or more first rows of outer balls 340 and two or more second rows of outer balls 350 . The substrate 310 has a packaging surface 311 and an exposed surface 312, wherein the packaging surface 311 includes a die-bonding region 313, such as Figure 8 As shown, the size of the die-bonding region 313 may be approximately equal to the size of the chip 330 . The exposed surface 312 of the substrate 310 may be formed with a solder mask layer 317, which is an insulating material, to form an electrically insulating layer covering the conductive traces, but exposing two or more external pads. 318, so that the first row of outer ball points 340 and the second row of outer ball points ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com