Cold rolled material production equipment and cold rolling method

A technology for manufacturing equipment and rolling mills, which is applied in the field of cold-rolled material manufacturing equipment and cold rolling, which can solve problems such as residues and reduce the reliability of joints, and achieve the effects of high yield, excellent effect, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

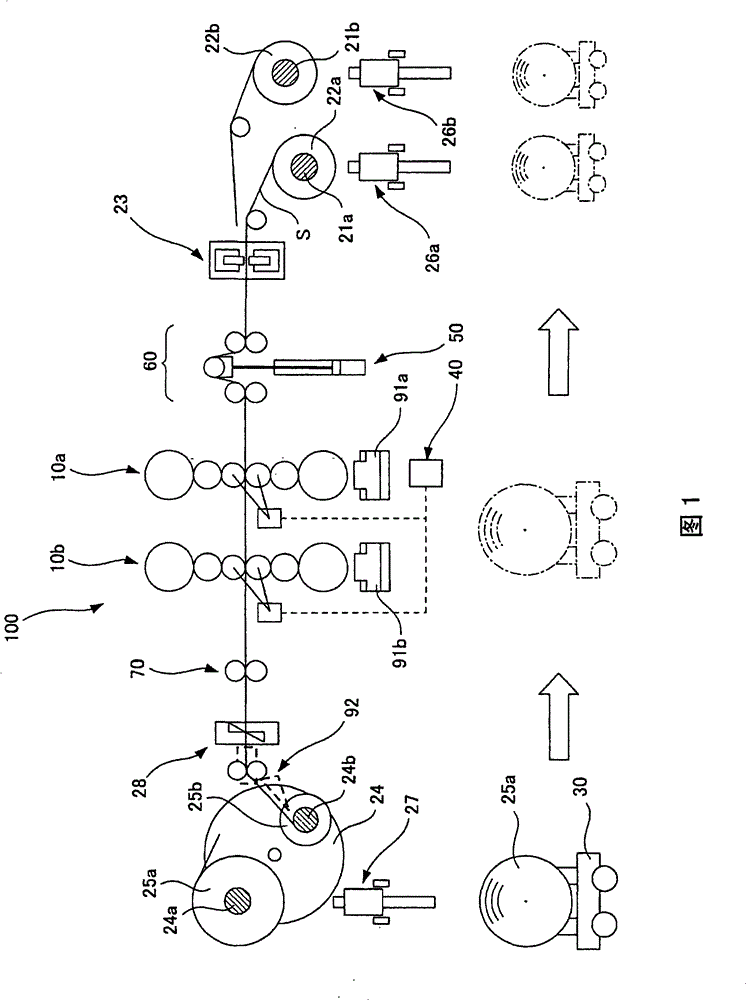

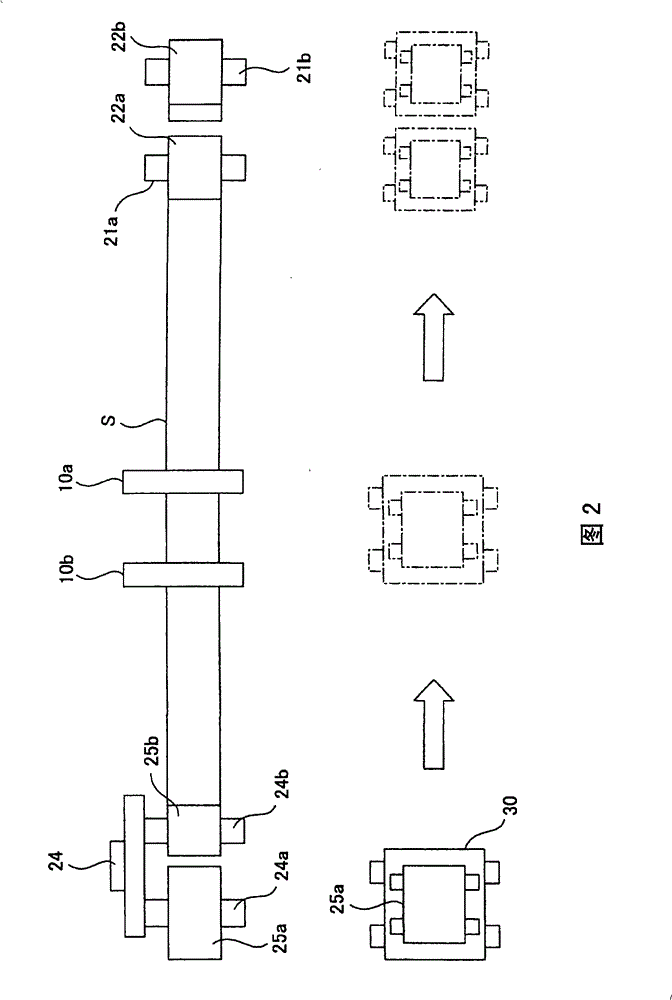

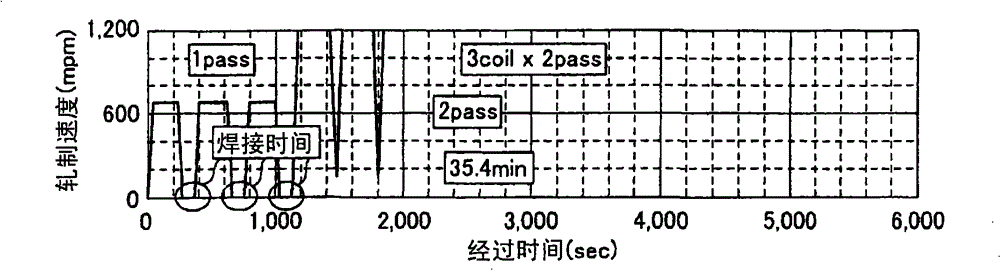

[0087] The operation of the cold-rolled material manufacturing facility and the cold-rolling method according to the embodiment of the present invention will be described below.

[0088] Make the rolling speed of the end of the leading coil and the front end of the following coil lower than the normal rolling speed during splicing, and shorten the strip storage length of the strip storage device arranged between the splicing device and the rolling machine , to miniaturize the device.

[0089] In the low-speed rolling condition, the plate thickness is measured by the plate thickness gauge installed on the exit side of the rolling mill, and the plate thickness control method is corrected based on the deviation between the plate thickness instruction value and the actual plate thickness value. Right below the work roll, the time from rolling to the plate thickness detection is delayed, and the plate thickness control accuracy decreases. Therefore, under low-speed rolling conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com