Method for preparing nano-magnesia with cotton cloth form

A nano-magnesium oxide, cotton cloth technology, applied in magnesium oxide, nanotechnology, nanotechnology and other directions, can solve the problems of complex process and low crystallinity, and achieve the effect of simple process, high specific surface area, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The method for preparing the nano magnesium oxide with cotton cloth form of the present invention, comprises the following steps:

[0024] (1) Mg(CH) with purity ≥99.0% 3 COO) 2 4H 2 O is made into a solution with a concentration of 0.8mol / L;

[0025] (2) After fully washing and drying the cotton cloth with distilled water, put it into the above prepared solution, seal and soak for 24 hours, take out the soaked cotton cloth, put it into a drying box, heat it to 80°C, and dry it at a constant temperature for 2 hours. Then carry out temperature-programmed roasting in flowing air: heat up to 800°C at a heating rate of 5°C / min, and hold the temperature for 1 hour to obtain biomorphic nano-magnesium oxide with a particle size of 15-40nm and a purity of 98.5-99.9%.

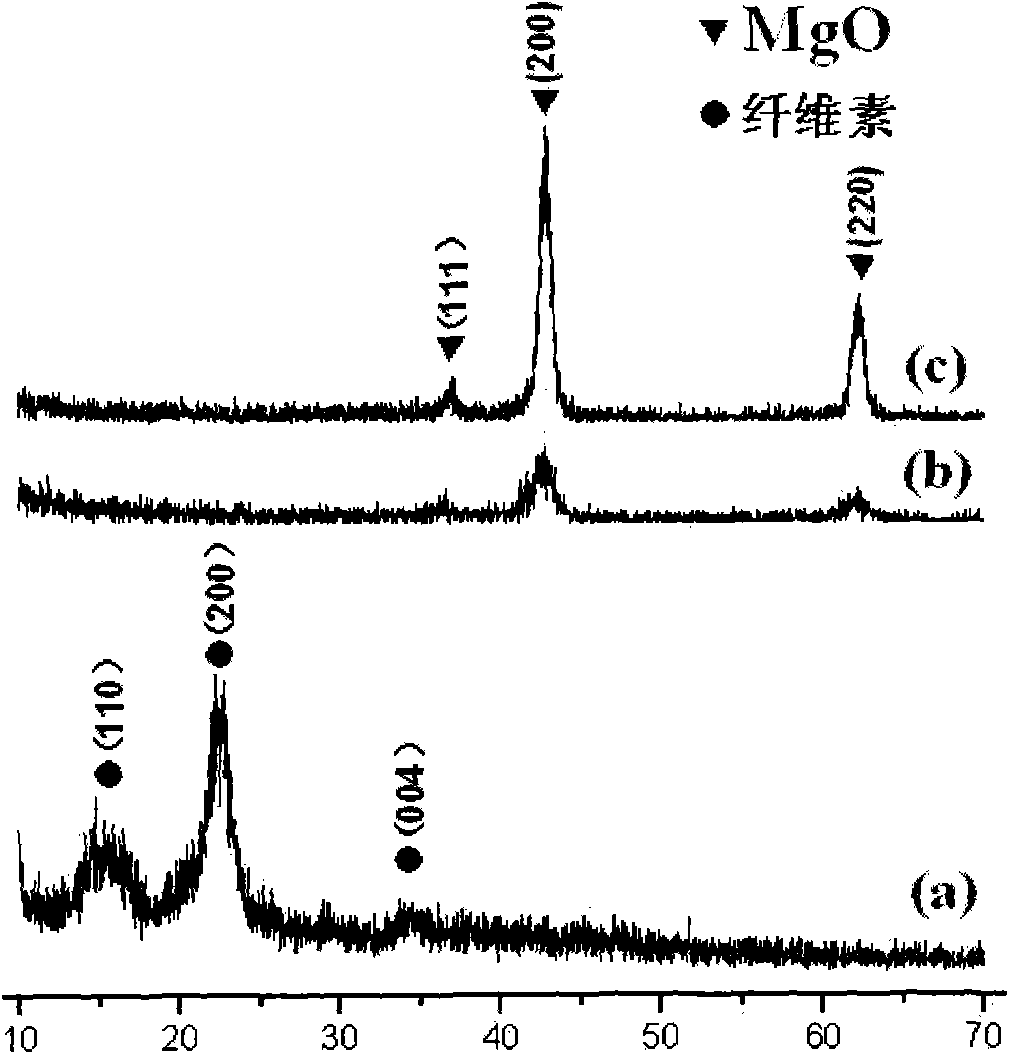

[0026] figure 1 (a) The curve shows that sintering at 300 °C, the sample has not undergone decomposition reaction, only the diffraction peaks corresponding to the (110), (200) and (004) crystal planes of cell...

Embodiment 2

[0034] The method for preparing the nano magnesium oxide with cotton cloth form of the present invention, comprises the following steps:

[0035] (1) Mg(CH) with purity ≥99.0% 3 COO) 2 4H 2 O is made into a solution with a concentration of 0.5mol / L;

[0036] (2) After fully washing and drying the cotton cloth with distilled water, put it into the above prepared solution, seal and soak for 24 hours, take out the soaked cotton cloth, put it into a drying box, heat it to 80°C, and dry it at a constant temperature for 2 hours. Then perform temperature-programmed roasting in flowing air: heat up to 500°C at a heating rate of 5°C / min, and keep the temperature for 1 hour to obtain biomorphic nano-magnesium oxide with a particle size of 10-25nm and a purity of 96.3-98.1.

Embodiment 3

[0038] The method for preparing the nano magnesium oxide with cotton cloth form of the present invention, comprises the following steps:

[0039] (1) Mg(CH) with purity ≥99.0% 3 COO) 2 4H 2 O is made into a solution with a concentration of 0.3mol / L;

[0040] (2) After fully washing and drying the cotton cloth with distilled water, put it into the above prepared solution, seal and soak for 12 hours, take out the soaked cotton cloth, put it into a drying box, heat it to 80°C, and dry it at a constant temperature for 2 hours. Then carry out temperature-programmed roasting in flowing air: heat up to 300°C at a heating rate of 5°C / min, and keep the temperature for 1 hour to obtain biomorphic nano-magnesium oxide with a particle size of 5-20nm and a purity of 87.6-88.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com