Improved production process of 1,3-Dimethyl-3,4,5,6-tetrahydro-2(1H)-pyrimidinone

A technology of dimethylpropylene urea and production process, applied in 1 field, can solve the problems of waste acid waste water pollution, formic acid corrosion and the like, and achieves the advantages of solving the corrosion problem, advanced production technology and process, and solving the problem of production cost and environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

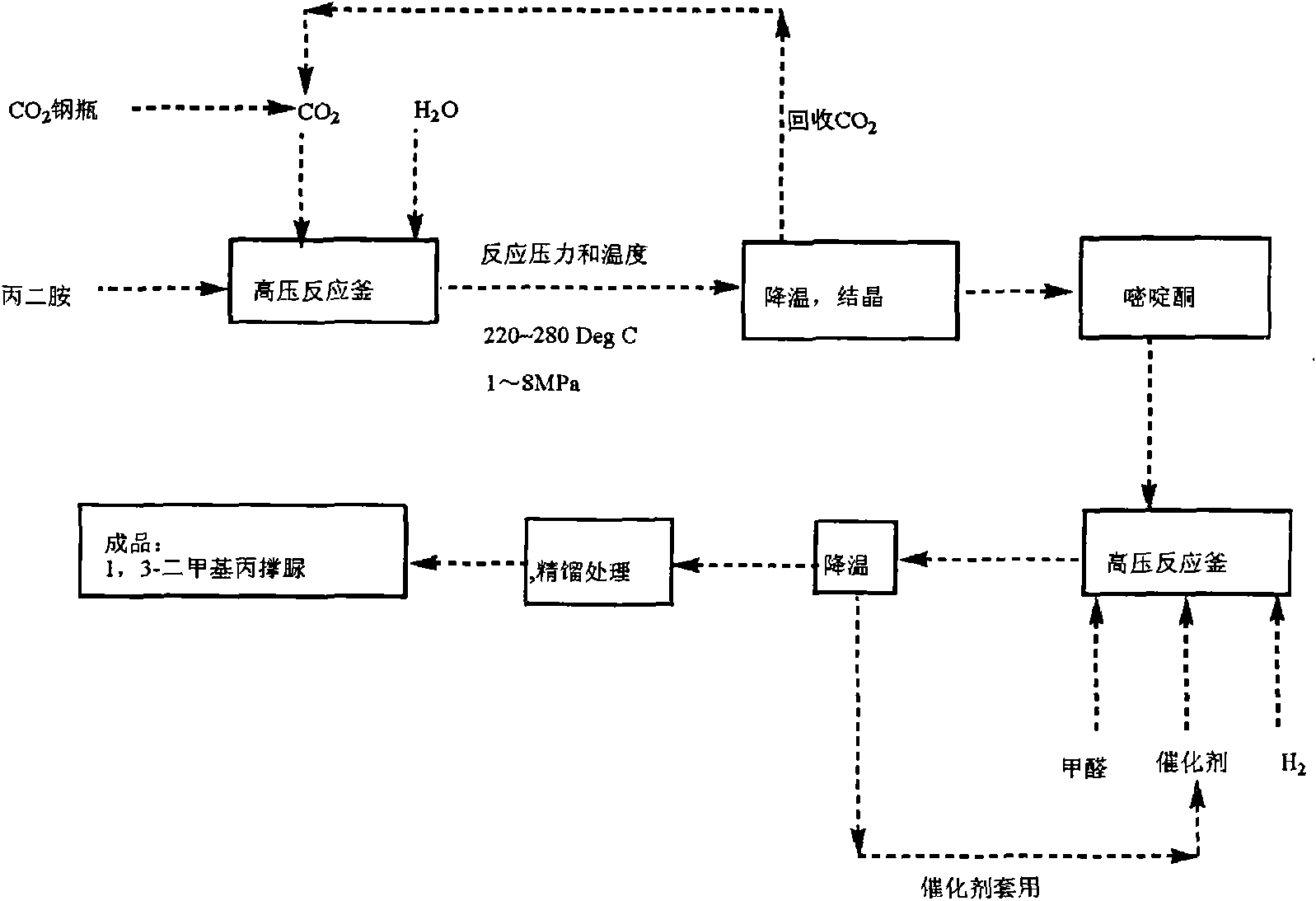

[0011] see figure 1 , in a 500L high-pressure reactor, add 62KG of urea (or 88kg of CO2), 60kg of deionized water, and 74KG of propylenediamine. After feeding, close the valve and replace it with nitrogen several times, then flush nitrogen at 1.5MPa, and start slowly Slowly raise the temperature to 250°C, keep the pressure of the reactor at 6MPa, react for 6 hours, cool down and release the pressure, recover the gas to obtain a solid pyrimidone, recrystallize with deionized water to obtain a pyrimidone intermediate with a content greater than 98%, and prepare for the following use in one step.

[0012] In a 2000L autoclave, add 200KG of the intermediate pyrimidinone produced in the front, 1kg of acidic Pd / C catalyst (catalyst formula 1Fe2O3.2Cr2O3.SO4+3Pd / Al2O3), 1500kg of 45% formaldehyde solution, and add the material , close the valve of the autoclave, replace with nitrogen several times, then pass in hydrogen, keep the temperature at 200 ° C, the pressure at 6 MPa, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com