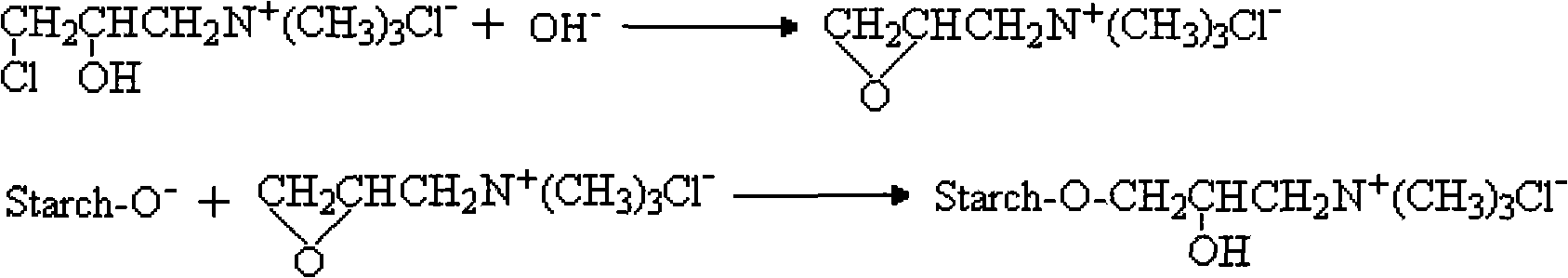

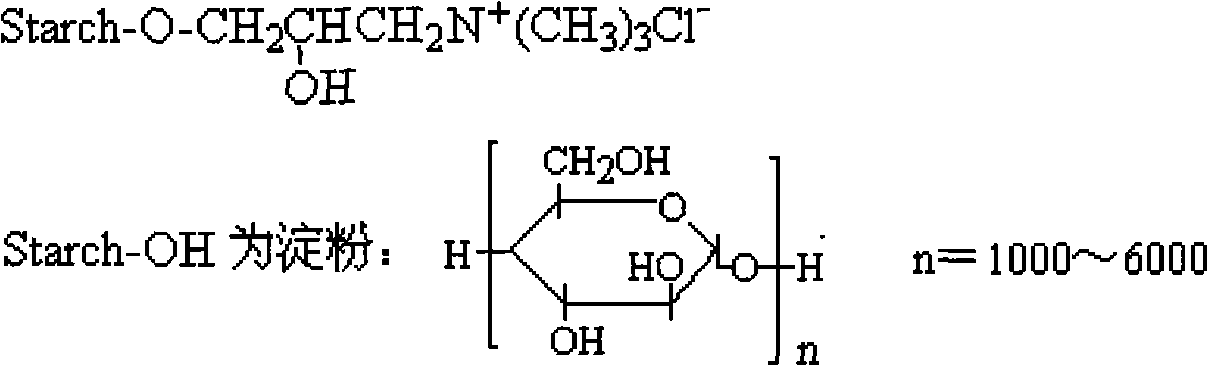

Cationic starch producing method

A cationic starch and production method technology, which is applied in the field of papermaking, can solve the problems of short storage time, low reaction efficiency, starch gelatinization, etc., and achieve the effects of good product quality, high reaction efficiency, and prevention of gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 20m 3 2 milk mixing tanks, equipped with an electric agitator and a circulation pump, add 69% cationic etherification agent with a content of 8.05% to the starch mass, and add 2.76% NaOH to the starch mass at a flow rate of 4000L / h through the circulation pipeline, with a concentration of 2.25 %NaOH solution, when the pH reaches 11.8, first add 1t of tapioca starch, then add 10kg / min of starch quality 6.3% Yuanmingfen, then add the remaining 15t of tapioca starch to control the feeding speed of 100kg / min, and control the pH at 11.6, starch suspension concentration 24.2 Baume. Then raise the temperature to 45°C and react for 8 hours, lower the temperature and neutralize the pH to 6.0 with 8% dilute hydrochloric acid, wash, dehydrate, and dry to obtain the finished product.

Embodiment 2

[0023] 20m 3 Two milk mixing tanks, equipped with an electric agitator and a circulation pump, add 69% cationic etherification agent with a content of 8.5% to the starch mass, and add 2.8% NaOH to the starch mass at a flow rate of 4000L / h through the circulation pipeline, with a concentration of 2.25 %NaOH solution, when the pH reaches 11.8, first add 1t of cornstarch, then add 5.75% of the starch quality of Yuan Mingfen at 10kg / min, then add the remaining 15t of cornstarch to control the feeding speed of 100kg / min, and control the pH at 11.5, starch suspension concentration 23 Baume. Then the temperature was raised to 48°C for 9h. Lower the temperature, neutralize the pH to 7.0 with 8% dilute hydrochloric acid, wash, dehydrate and dry to obtain the finished product.

Embodiment 3

[0025] 20m 3 Two milk mixing tanks, equipped with an electric agitator and a circulation pump, add 69% cationic etherification agent with a content of 10% of the starch mass, and add 3.0% NaOH to the starch mass at a flow rate of 4000L / h through the circulation pipeline, with a concentration of 2.25 %NaOH solution, when the pH reaches 11.8, first add 1t of cornstarch, then add 7.0% starch starch at 10kg / min, then add the remaining 15t of cornstarch to control the feeding speed of 100kg / min, and control the pH at 11.6, starch suspension concentration 24 Baume. Then the temperature was raised to 48°C for 8h. Cool down, add dilute hydrochloric acid with a concentration of 8% to neutralize the pH to 8.0, wash, dehydrate and dry to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com