Heat treatment facility for soft magnetic winding core in transverse magnetic field and method thereof

A technology for heat treatment equipment and winding iron cores, applied in heat treatment equipment, heat treatment furnaces, furnaces, etc., can solve the problems of high price, power consumption and high failure rate, and achieve the effects of simple structure, high price and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

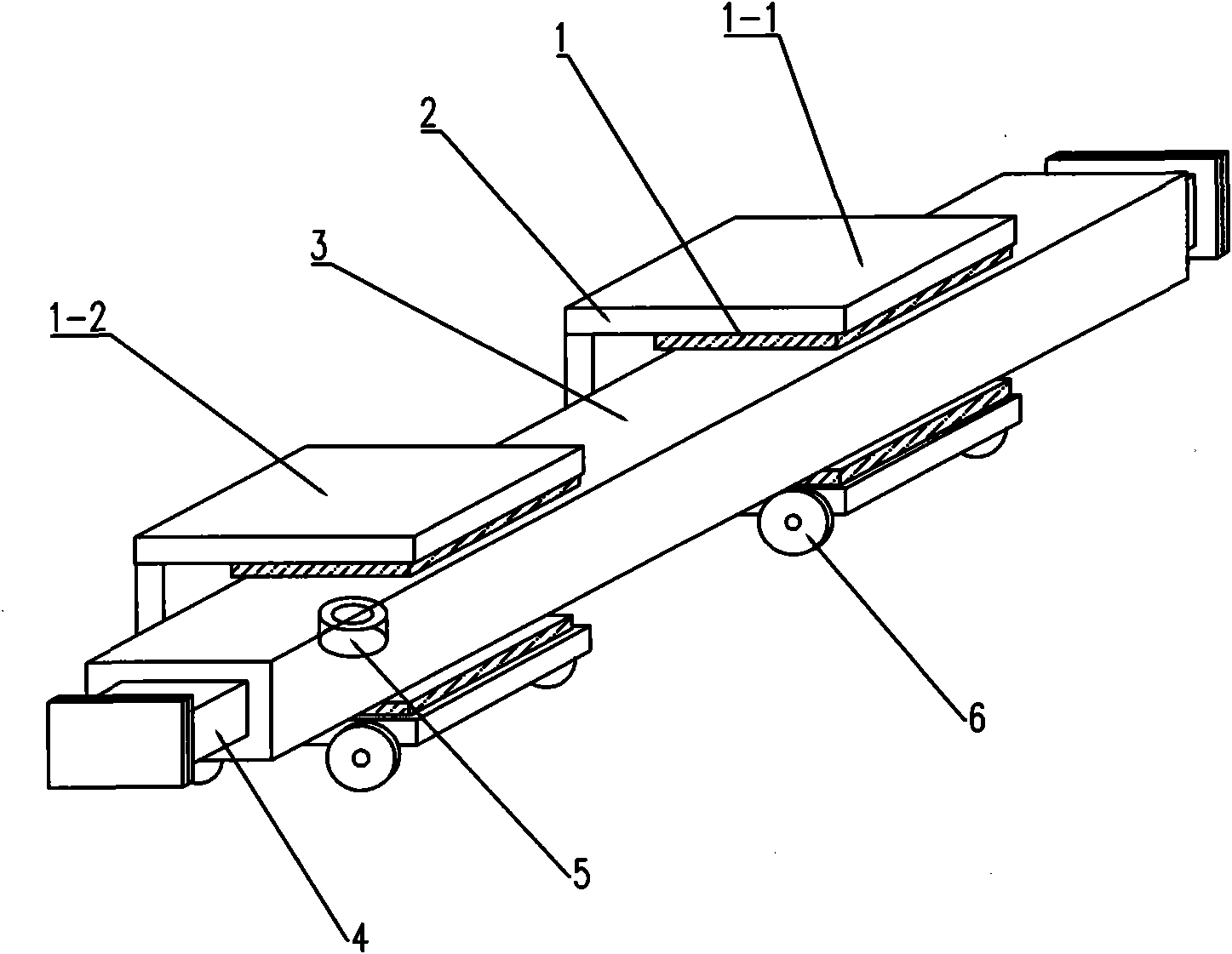

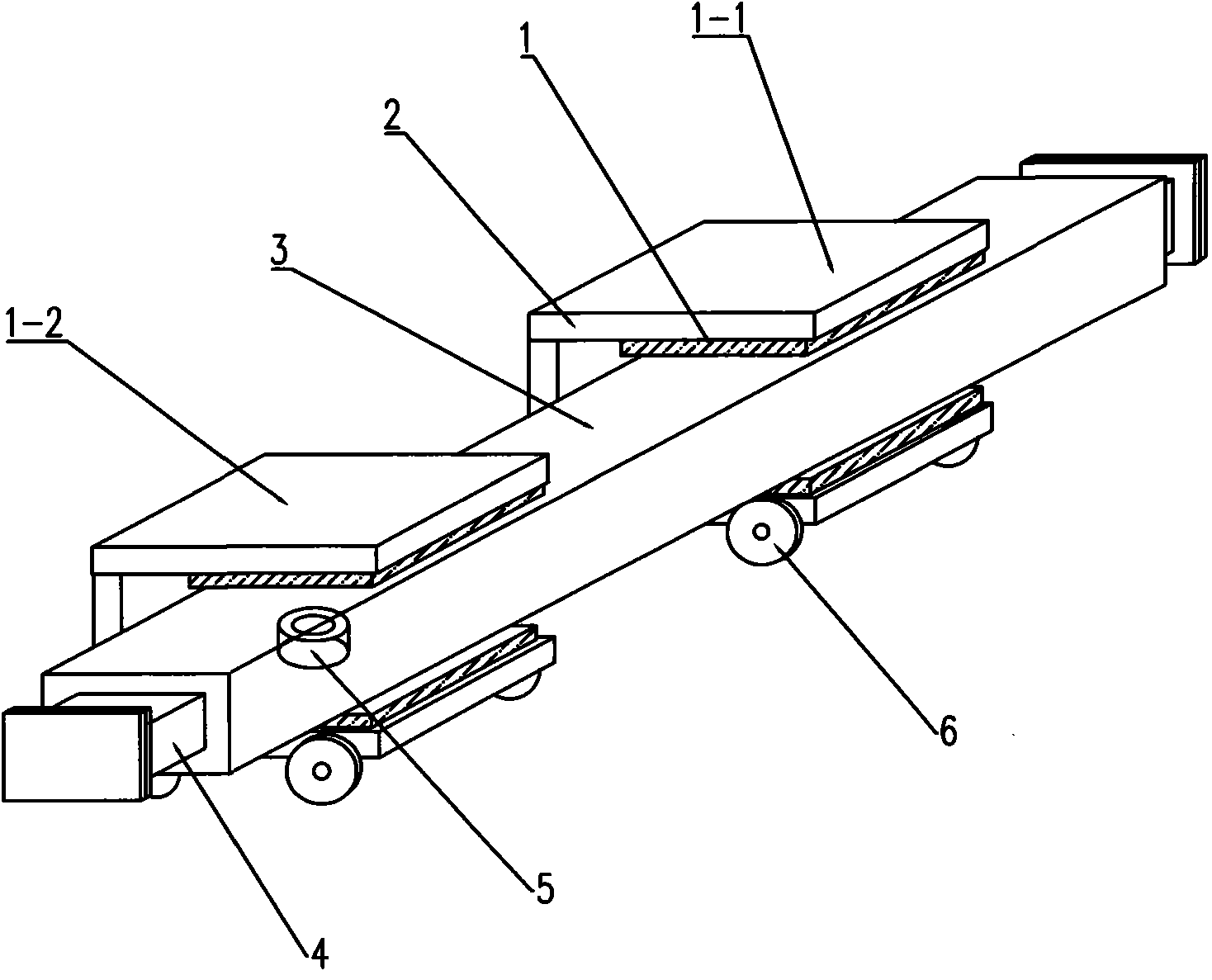

[0026] Such as figure 1 As shown, the present invention is a kind of heat treatment equipment and method of soft magnetic winding iron core under transverse magnetic field, which includes a longitudinal continuous tunnel annealing furnace 3, above and below the uniform temperature section of the longitudinal continuous tunnel annealing furnace 3 , respectively place a NdFeB magnetic pole 1 N and S pole square plate, between the magnetic pole plates generate a strong magnetic force line from N to S along the vertical direction, the magnetic pole plate is spliced by a number of small square magnetic poles, the magnetic poles The plate area is slightly larger than the area of the tray where the iron core workpiece 5 is placed in the furnace. The outer surfaces of the upper and lower magnetic pole plates are connected with a C-shaped magnetic yoke 2 made of pure iron to form a magnetic circuit. Move, each pair of N-S magnetic poles can be separated from or inserted into the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com