Classification alarm and identification auxiliary method of real-time production parameters of power plant

A parameter classification and power plant technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as manual intervention reset, failure to issue alarms, large deviation between alarm parameter setting values and actual values, etc., to reduce labor intensity , rapid response, and the effect of improving the quality of supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

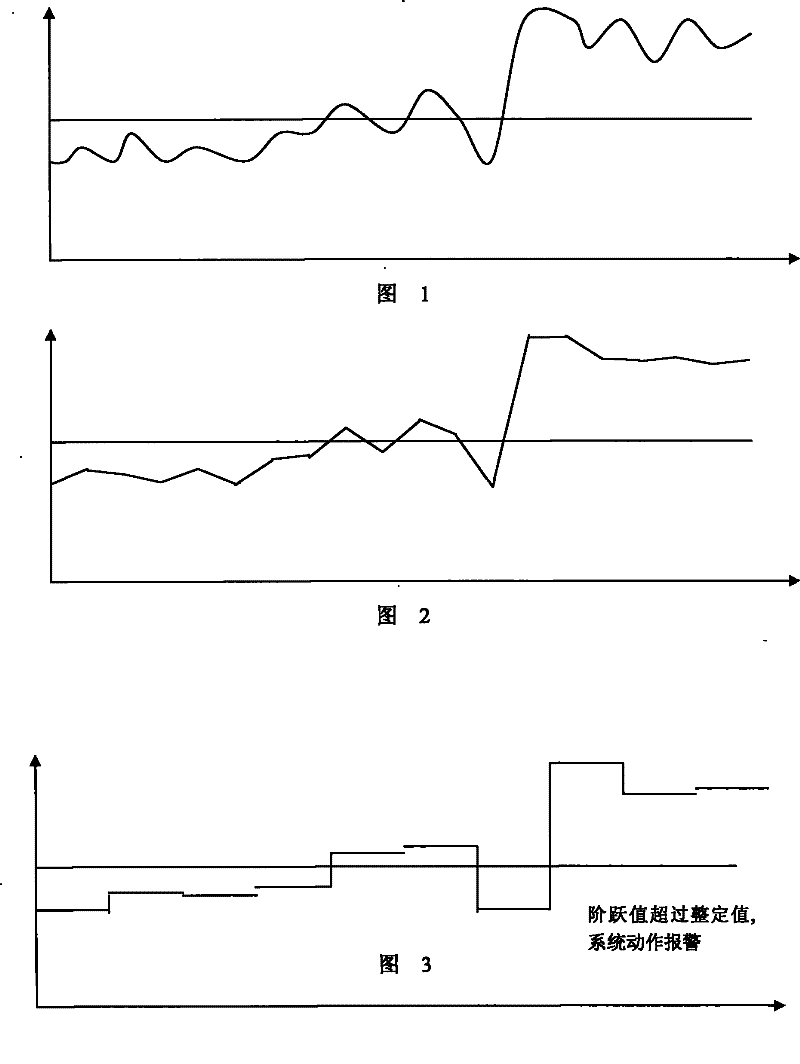

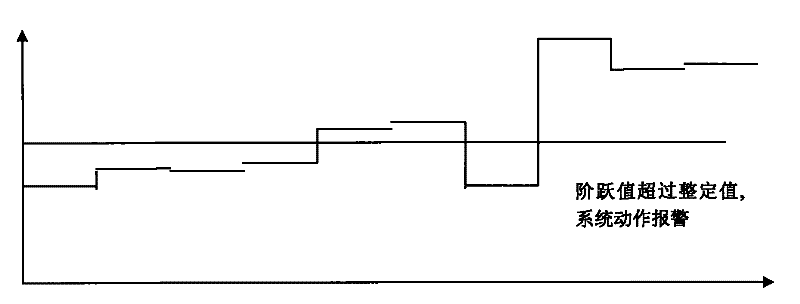

[0048] The production real-time parameter classification alarm and identification auxiliary method of the power plant first scans the equipment parameters of the steam turbine generator set through the production real-time system, such as including No. 1 unit, No. 2 unit, coal yard, chemical control, ash control, fire protection, etc. The equipment groups that make up the steam turbine generator set are divided into two types: production equipment and measurement equipment. When these two types of equipment fail, according to the rules of equipment parameter changes, classification alarms and identification are carried out.

[0049] All available parameters are divided into three categories:

[0050] 1) Parameters that change with load rules, such as regulating stage pressure, total coal volume, etc.;

[0051] 2) Parameters that are basically constant with the load, such as seal oil hydrogen differential pressure, fan bearing temperature, etc.;

[0052] 3) Does not change wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com