Fuel cell engine system and starting method thereof

An engine system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve problems such as complex control systems, troublesome startup, and poor reliability of lithium batteries, and achieve simple system structure and convenient startup and operation , the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiment that accompanying drawing provides.

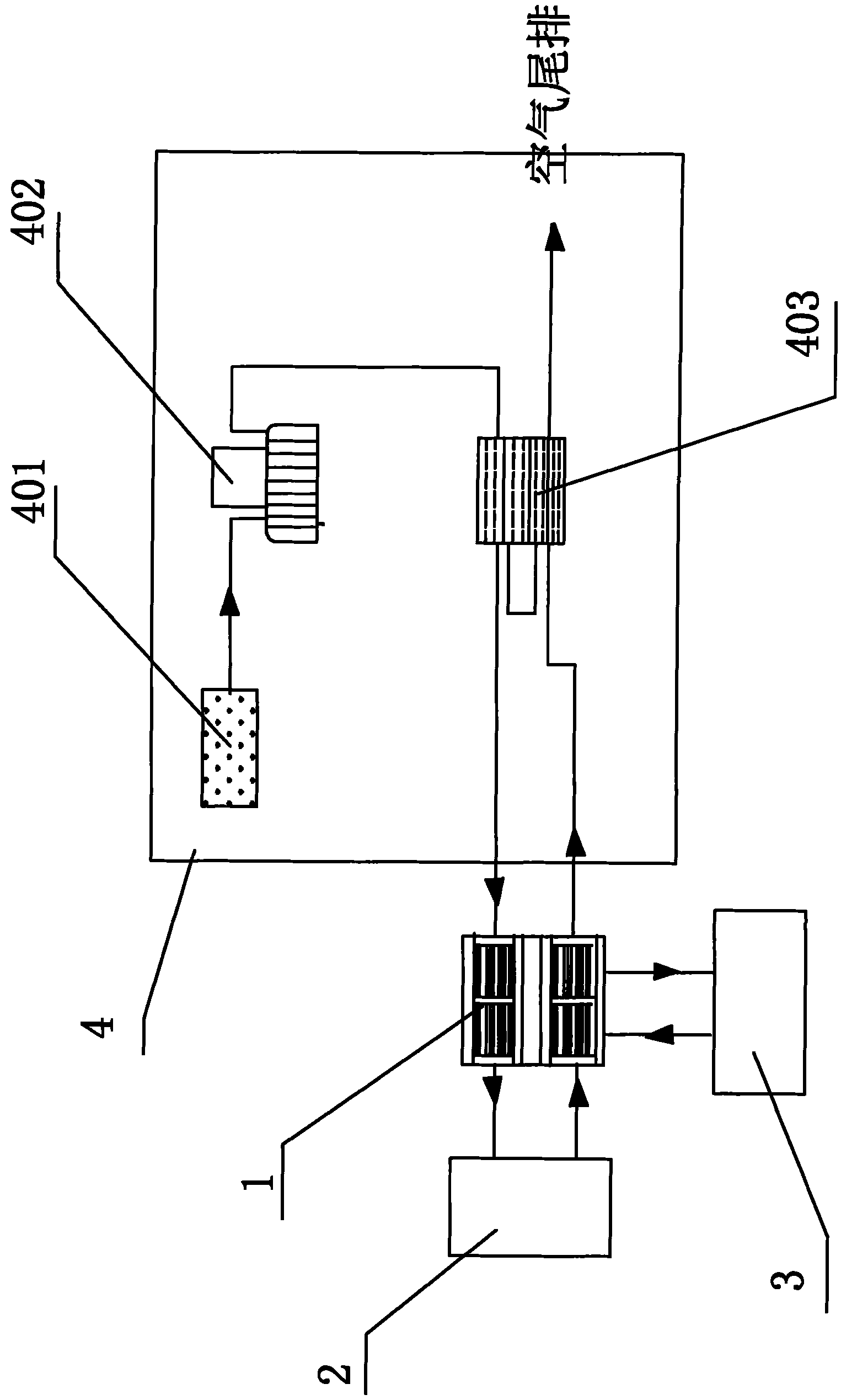

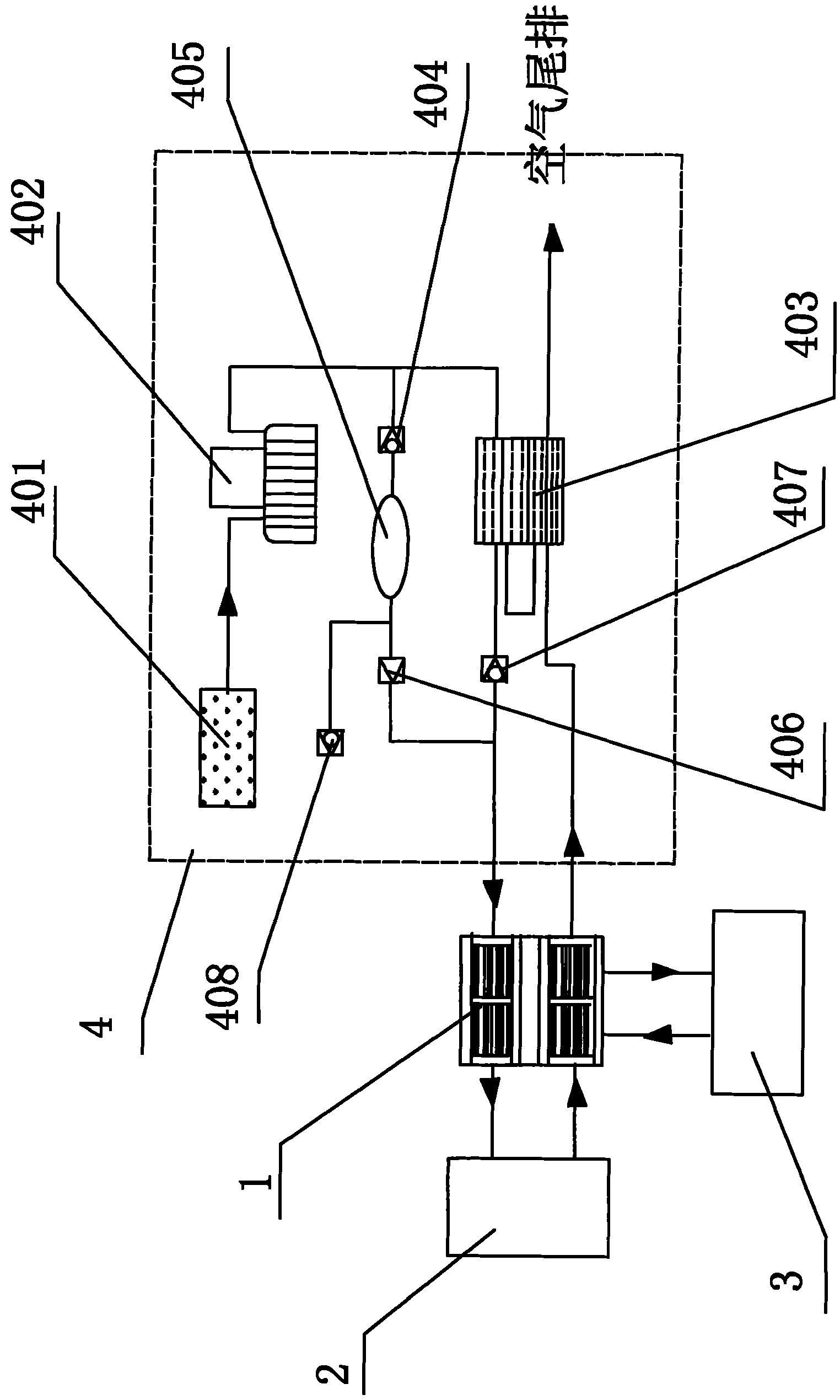

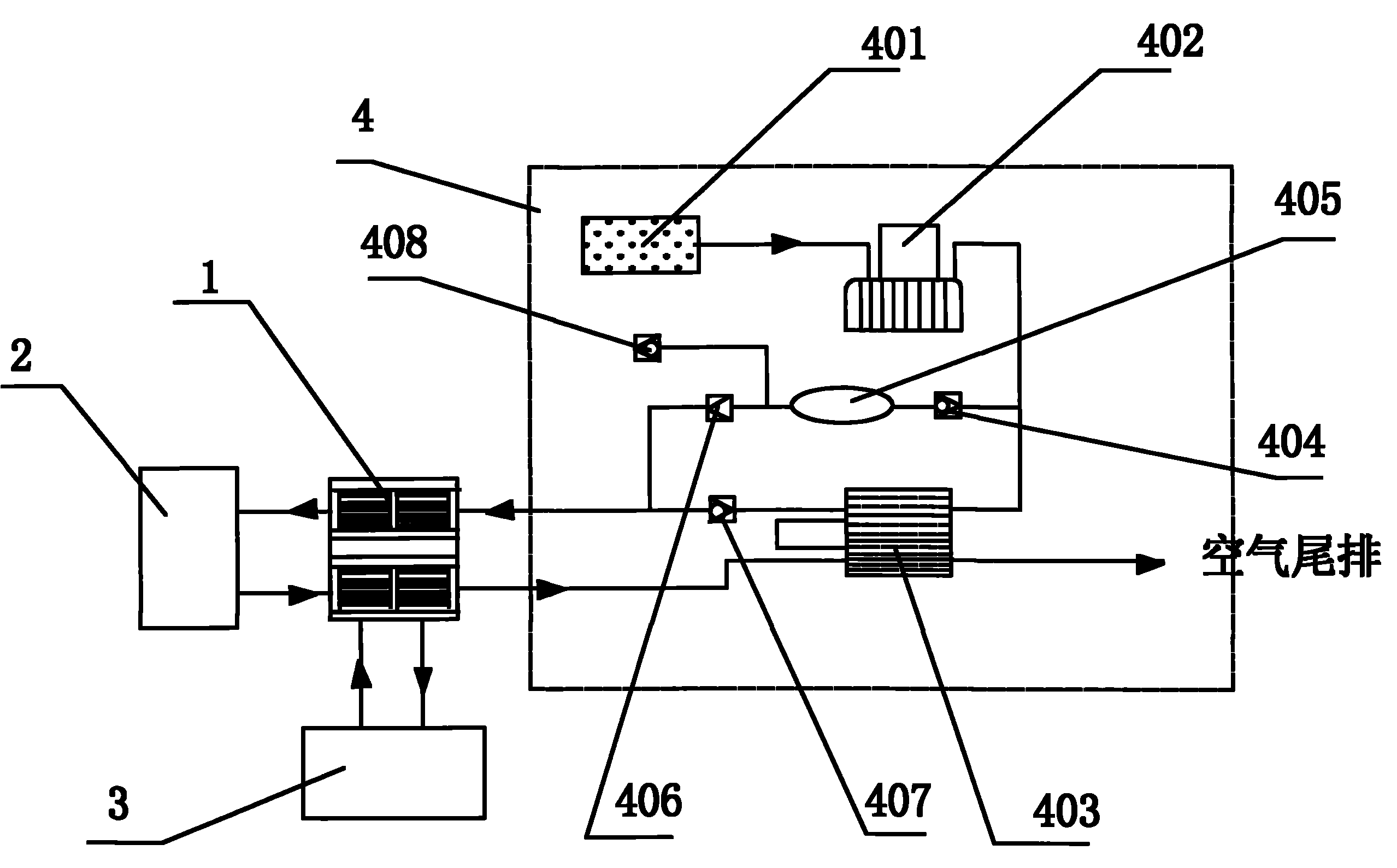

[0025] The embodiment is a 10kW fuel cell engine system with a maximum air operating pressure of 0.05MPa, including a fuel cell stack 1 , a hydrogen system 2 , an air system 4 and a cooling system 3 . The air system includes an air filter 401, an air supply device 402 and a wet enthalpy conversion device 403 connected by pipelines, and an outlet is connected in series on the pipeline between the air outlet of the wet enthalpy conversion device 403 and the air inlet of the fuel cell stack 1 One-way valve 407, the air outlet of the outlet one-way valve 407 is connected with the air inlet of the fuel cell stack 1, the air inlet of the outlet one-way valve 407 is connected with the air outlet of the wet enthalpy conversion device 403; the air system also includes an additional branch The additional branch is composed of an additional branch check va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com