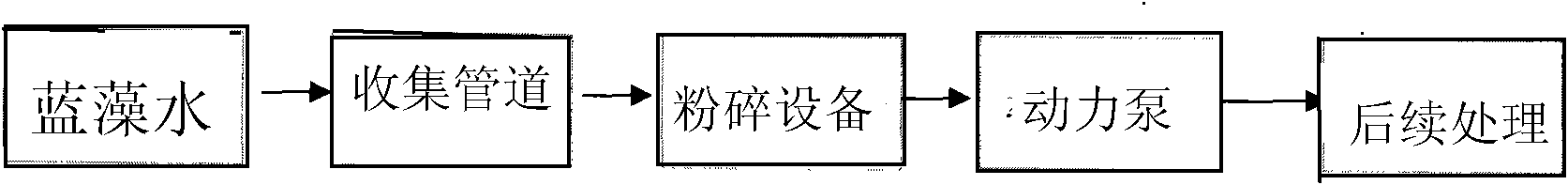

Blue algae collection system

A collection system, cyanobacteria technology, applied in the direction of dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, inconvenient operation, high manufacturing cost, etc., to achieve The effect of comprehensive utilization value improvement, extended service life, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

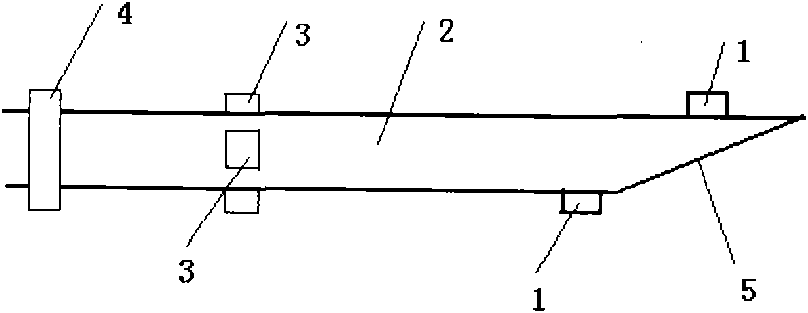

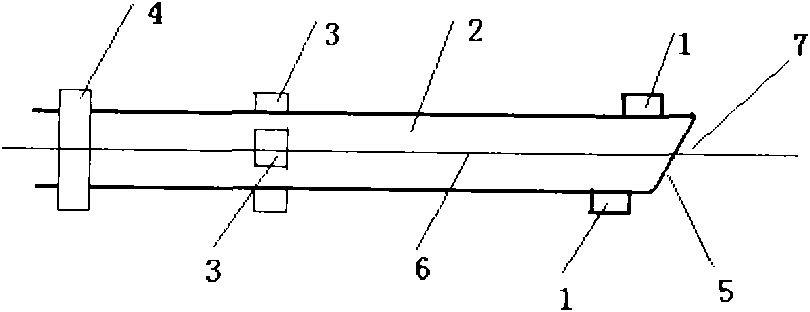

Embodiment 1

[0017] Embodiment 1: Collection pipeline 2, gear pulverizer, and power pump form the collection system, and the gear pulverizer and power pump are installed at the rear of the collection pipeline in sequence and connected in sequence with commercially available ordinary pipelines. Floaters 3 and 4 are installed on the collection pipe 2, and the floaters are limited to being able to float the pipe, and can be fixed in blocks or rings; a gravity regulator 1 is installed on the outer surfaces of the longest axial end and the shortest end of the pipe respectively , can be realized by methods such as adding and subtracting weights with scale hooks, adding and subtracting weights with welded storage baskets, and directly binding gravity weights; the angle between the plane formed by the collection port 5 of the collection pipe 2 and the central axis 6 of the collection pipe 7 is 20 degrees.

[0018] The cyanobacteria water is first sucked through the collection pipeline 2, the gear ...

Embodiment 2

[0019] Embodiment 2: In Embodiment 1, the gravity regulator 1 is changed to only install one gravity regulator 1 on the outer surface of the axially longest end of the pipeline.

Embodiment 3

[0020] Embodiment 3: In Embodiment 1, the gravity regulator 1 is changed to only install one gravity regulator 1 on the outer surface of the axially shortest end of the pipeline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com