Synthetic method of 2, 3-dibromo-2-methylpropanoic acid

A technique for the synthesis of methacrylic acid, which is applied in chemical instruments and methods, carboxylate preparation, organic compound preparation, etc., can solve the problems of harm to the human body and the environment, low yield, and potential safety hazards, and achieve operational Simple and convenient, high yield, avoiding the effect of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

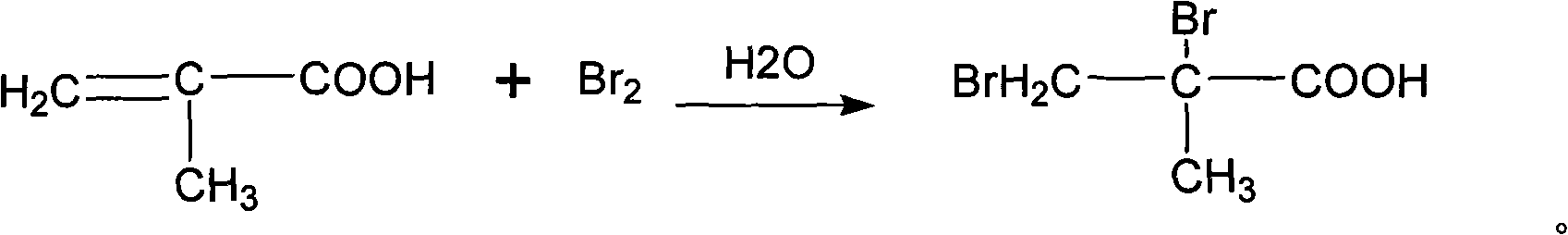

[0020] Embodiment 1, a kind of synthetic method of 2,3-dibromo-2-methyl propionic acid, take methacrylic acid and bromine as raw material, carry out following steps successively:

[0021] 1) Weigh methacrylic acid (40g, 0.4646mol) into a three-necked flask, add 40ml of water, heat up to 100°C under stirring, add bromine (74.4g, 0.4646mol) dropwise, drop it in about 30 minutes, continue to React at 100°C for 1 h; after the reaction, the crude product of 2,3-dibromo-2-methylpropionic acid was obtained.

[0022] 2), the above crude liquid is cooled to below 5°C (for example, 0°C) for crystallization, and then suction filtered to obtain the mother liquor and solid; the above solid is washed with cold water for 2 to 3 times, and after drying, 113g of light yellow solid is obtained. The light yellow solid is 2,3-dibromo-2-methylpropionic acid with a purity of 99.5% and a melting point of 46-48°C. The yield was 98.8%.

Embodiment 2

[0023] Embodiment 2, a kind of synthetic method of 2,3-dibromo-2-methyl propionic acid, take methacrylic acid and bromine as raw material, carry out the following steps successively:

[0024] 1) Weigh methacrylic acid (40g, 0.4646mol) into a three-necked flask, add 160ml of water, heat up to 75°C under stirring, add bromine (74.4g, 0.4646mol) dropwise, drop it in about 30 minutes, continue to Reaction at 75°C for 3h; after the reaction, the crude product of 2,3-dibromo-2-methylpropionic acid was obtained.

[0025] 2), cooling the above crude liquid to below 5°C (for example, 0°C) for crystallization, and then suction filtration to obtain the mother liquor and solid; washing the above solid with cold water for 2 to 3 times, and drying to obtain 111g of light yellow solid, the The light yellow solid is 2,3-dibromo-2-methylpropionic acid with a purity of 99.8% and a melting point of 46-47°C. The yield was 97.1%.

Embodiment 3

[0026] Embodiment 3, a kind of synthetic method of 2,3-dibromo-2-methyl propionic acid, take methacrylic acid and bromine as raw material, carry out the following steps successively:

[0027] 1) Weigh methacrylic acid (40g, 0.4646mol) into a three-necked flask, add 320ml ml water, heat up to 75°C under stirring, add bromine (223.2g, 1.3938mol) dropwise, drop it in about 30 minutes, continue React at 75°C for 1 h; after the reaction, the crude product of 2,3-dibromo-2-methylpropionic acid is obtained.

[0028] 2), cooling the above crude liquid to below 5°C (for example, 0°C) for crystallization, and then suction filtration to obtain the mother liquor and solid; washing the above solid with cold water 2 to 3 times, and drying to obtain 113.2 g of light yellow solid, The light yellow solid is 2,3-dibromo-2-methylpropionic acid with a purity of 99.6% and a melting point of 46-48°C. The yield was 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com