Oil shale dry-process coking method and water spraying structure of gas retort

A dry distillation furnace and oil shale technology, which is used in coke ovens, coke cooling, special forms of dry distillation, etc., can solve the problems of easy freezing, large water consumption, pollution, etc., to reduce investment and daily management costs, reduce Heat supply, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

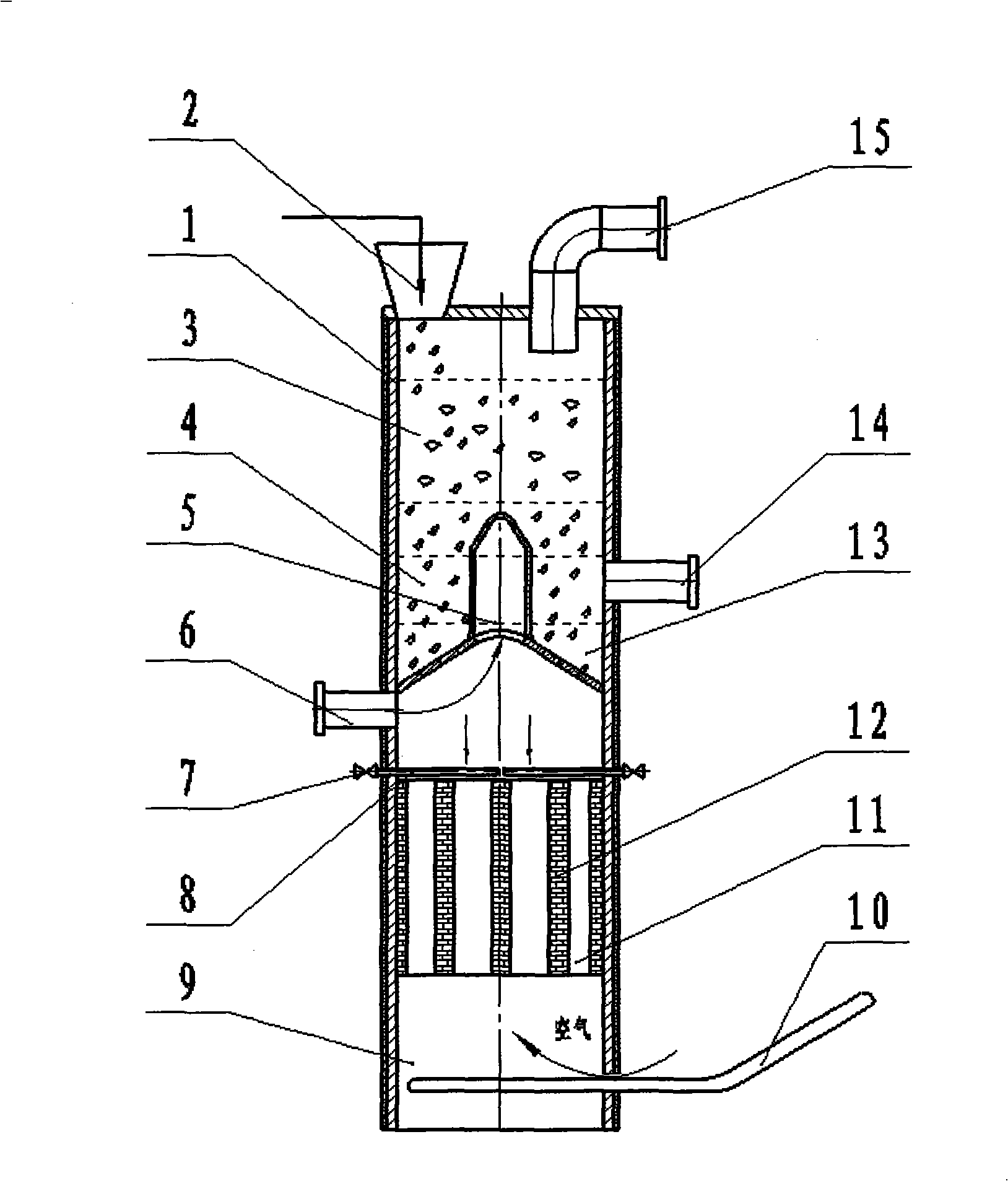

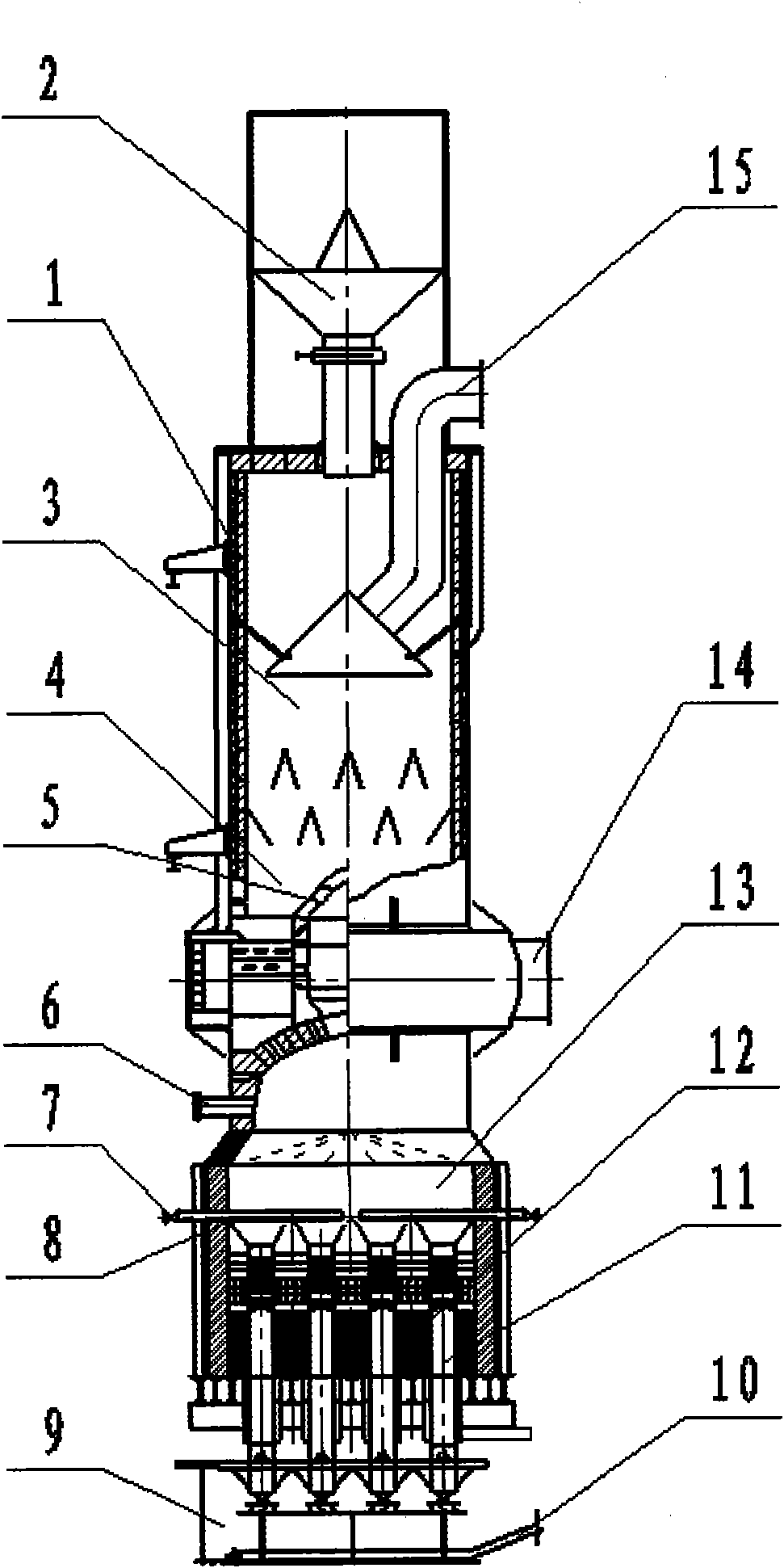

[0028] The specific implementation method on the 300-ton oil shale retort furnace in Huadian type is: see figure 1 , figure 2 ,

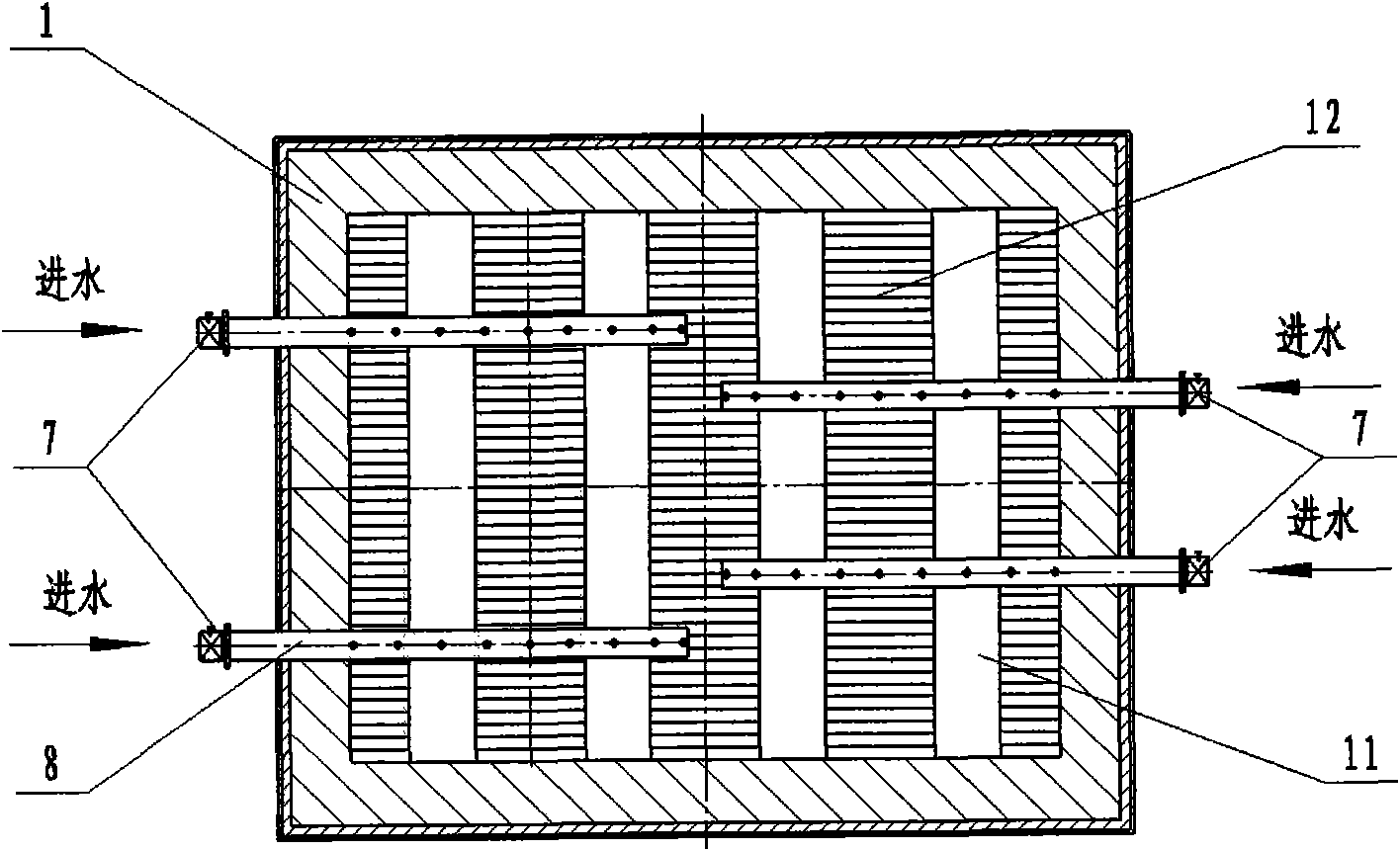

[0029] Change the cold cycle gas inlet entering into the original retort furnace (the applicant's prior application 200810228891.0, "300 tons of oil shale gas full cycle retort furnace per day") into saturated water vapor inlet 6, and install a spray nozzle at its lower part Water structure: the water inlet pipe with the regulating valve 7 is connected with the water spray pipe 8 arranged in the furnace, and the water spray pipe 8 has a water spray hole. The water of 25 ℃-80 ℃ is ejected by the spray hole of water spray pipe 8, or feeds steam from steam inlet 6 simultaneously, also can only use one; The pressure of water is 8000Pa, and steam pressure is 7500Pa. Both steam and water are obtained from the heat recovered from the waste heat boiler in the dry distillation system, without adding a new heat source. The ratio of water vapor and water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com