Method and system for laser deicing for power transmission and transformation equipment

A power transmission and transformation equipment and laser technology, applied in the field of laser applications, can solve the problems of small area of icing area, difficult to achieve, and increase the laser action distance, and achieve the effect of removing large-area icing, avoiding damage, and being light in weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

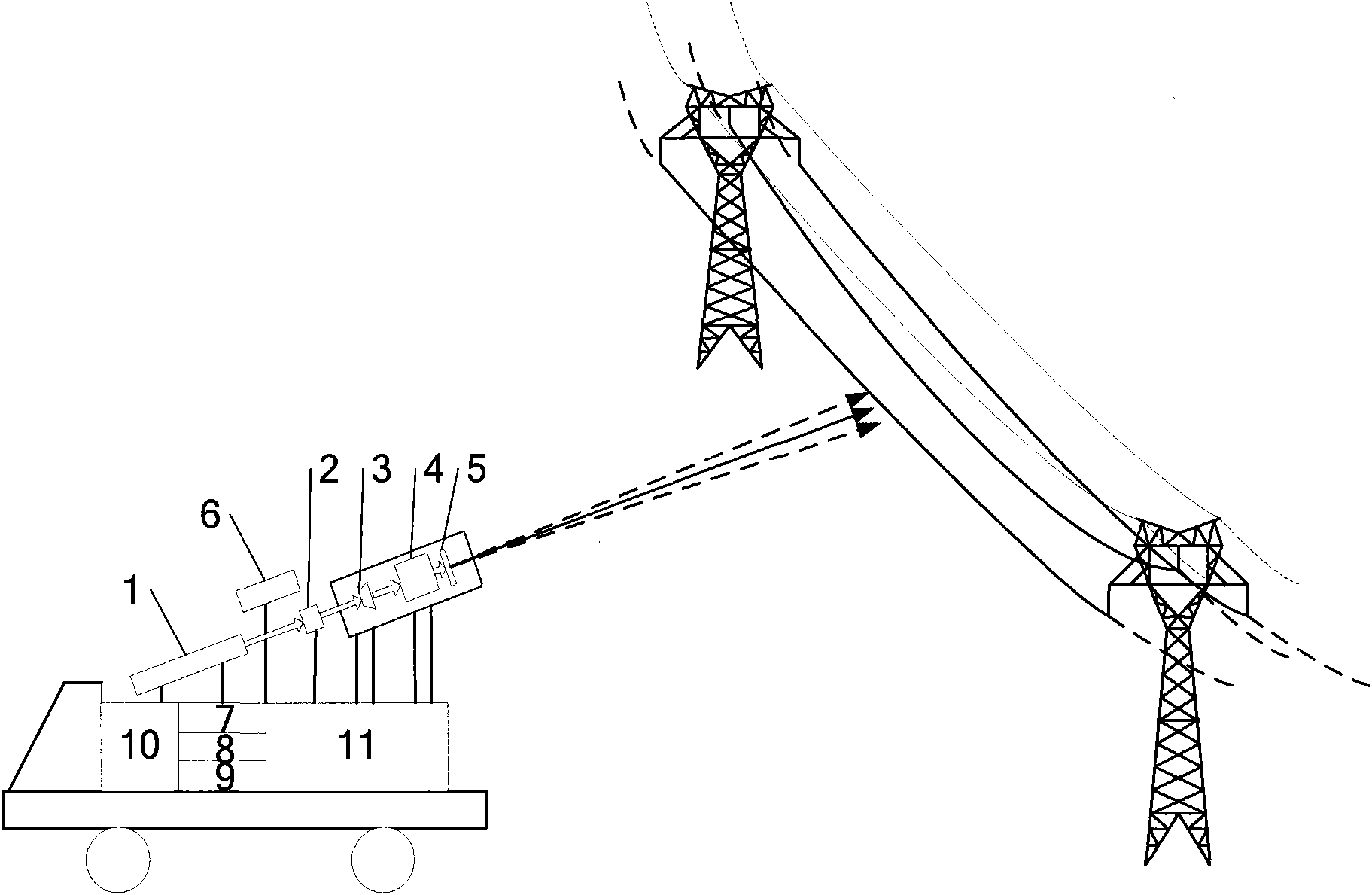

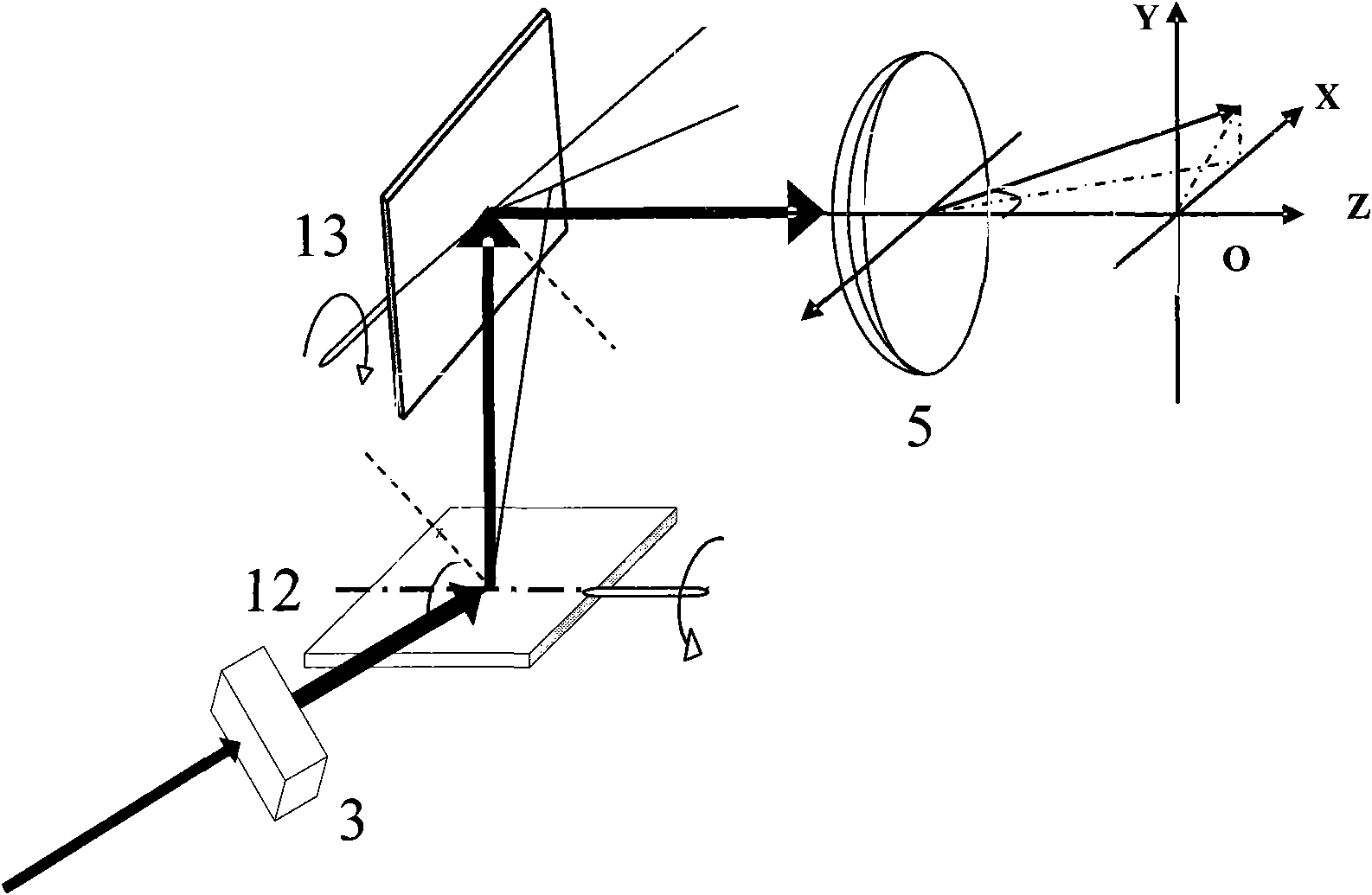

[0015] The deicing system is placed on a mobile device, such as a vehicle, driving to a distance of 100m to 1000m from the ice-covered power transmission and transformation equipment, starting the laser to make the laser output power smaller, and adjusting the elevation angle of the laser head 1 so that the laser can be transmitted over a long distance On the ice of power transmission and transformation equipment, at the same time ensure that the frequency conversion device 2, beam expander 3, scanning galvanometer 4 and focusing mirror 5 are on the same optical axis as the laser head 1. The infrared laser output by the laser head 1 passes through the frequency conversion device 2, and part of it is converted into visible laser light. The focusing of the visible laser light is observed through the aiming device 6, and the laser irradiation position is determined. Since the visible laser and the infrared laser are output coaxially, the output can be guaranteed. The infrared lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com