Preparation method of multi-light metal coordination aluminum hydride hydrogen storage material

An aluminum hydride, hydrogen storage material technology, applied in metal hydride, chemical instruments and methods, hydrogen production and other directions, to achieve the effects of simple raw materials, high production efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

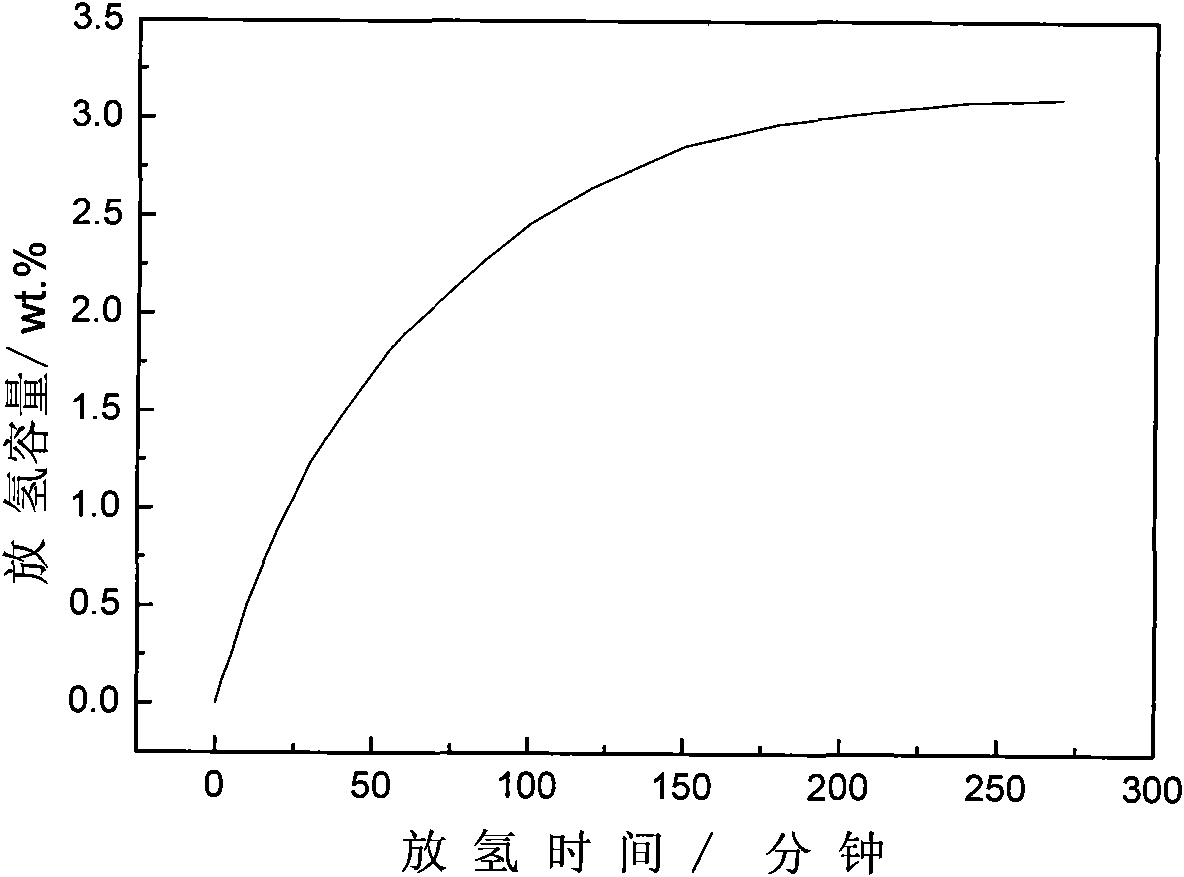

Embodiment 1

[0020] Na according to the chemical formula x Li 3-x H 6 Coordination hydride hydrogen storage material, x=1.8 constitutes Na 1.8 Li 1.2 H 6 Coordinated hydrides. With NaH, LiH and Al powder as raw materials, elemental Ti powder as catalyst, calculate the weight ratio of LiH, NaH and Al powder according to NaH: LiH: Al=1.8: 1.2: 1 (molar ratio), then press (NaH+LiH +Al) is 4 mol.% of the total molar weight to calculate the doping amount of Ti powder. The purity of the above-mentioned NaH is ≥95%, and the particle size is 74 μm; the purity of LiH is ≥97%, and the particle size is 74 μm; the purity of Al powder is ≥99%, and the particle size is 74-154 μm; the purity of Ti powder is ≥99%, and the particle size is -3 bar, then filled with 3.5MPa hydrogen with a purity greater than 99.9%, and then ball milled at room temperature for 120h. Prepared Na 1.8 Li 1.2 H 6 The measured hydrogen discharge capacity at the first hydrogen discharge is 3.10wt.%.

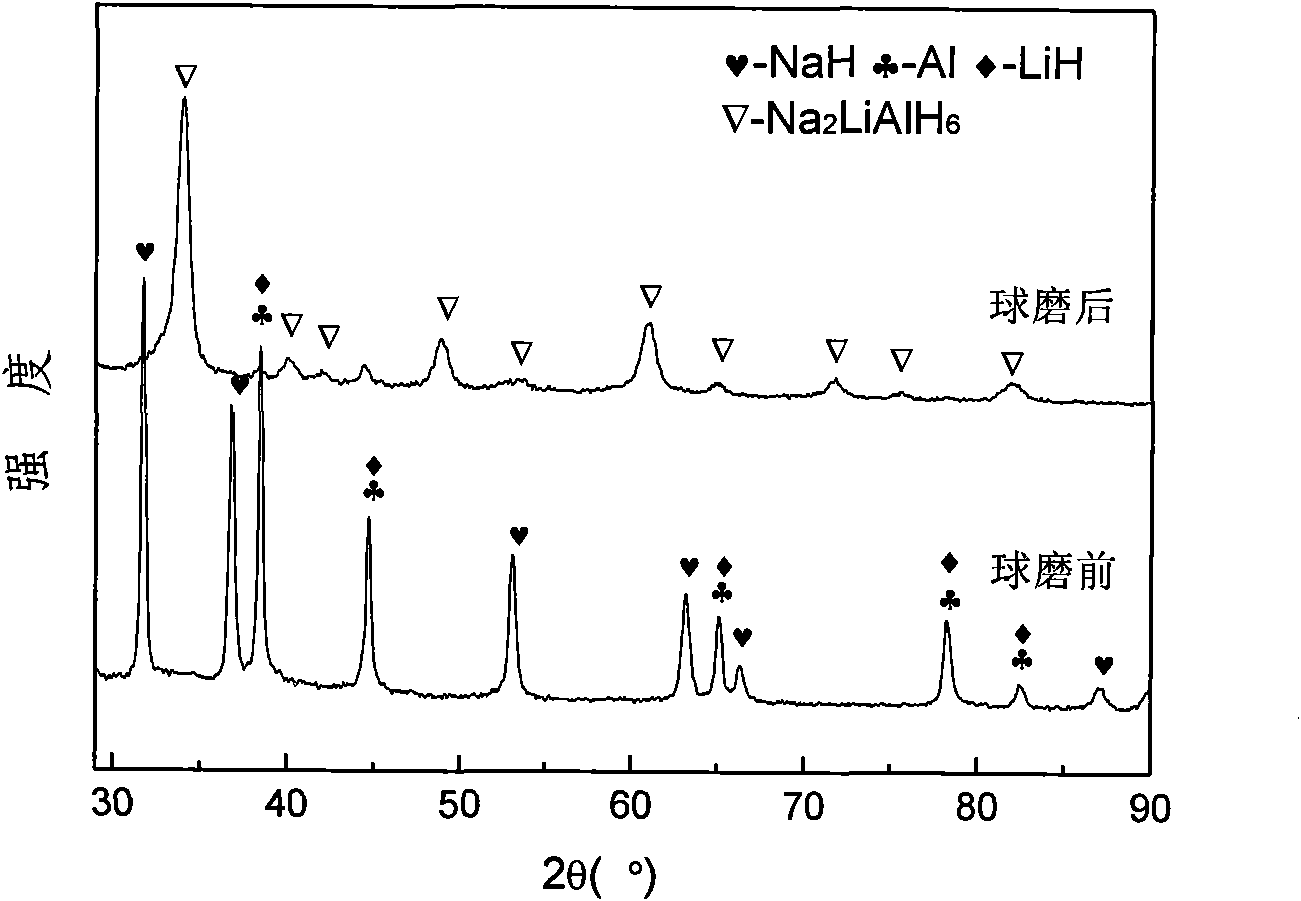

[0021] The main chem...

Embodiment 2

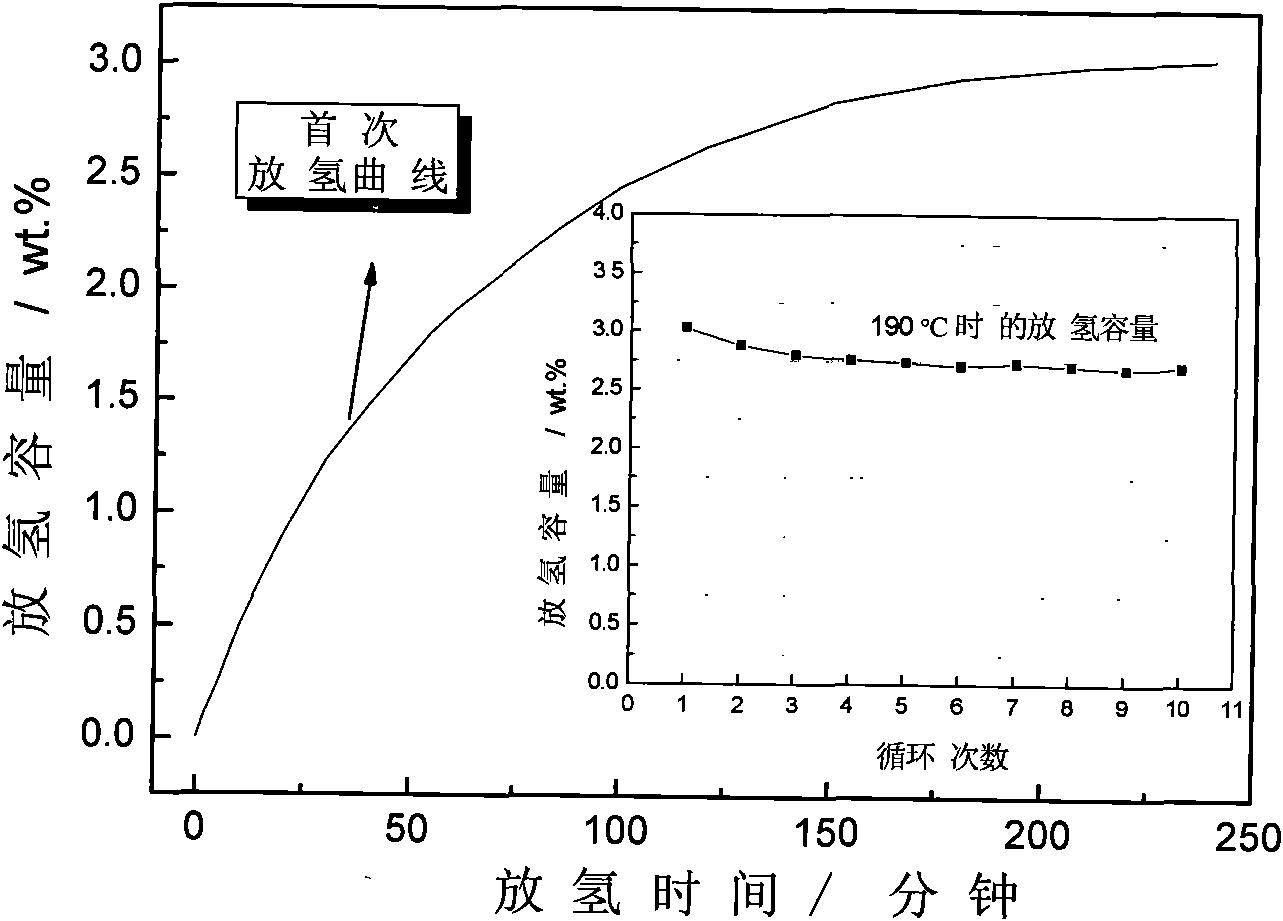

[0025] Na according to the chemical formula x Li 3-x H 6 Coordination hydride hydrogen storage material, x=2, that is to form Na 2 LiAlH 6 Coordinated hydrides. Using NaH, LiH and Al powder as raw materials, TiF 3 As a catalyst, calculate the weight ratio of NaH, LiH and Al powder according to NaH:LiH:Al=2:1:1 (molar ratio), and then calculate TiF according to 2mol.% of the total molar weight of (NaH+LiH+Al) 3the amount of doping. The purity of the above-mentioned NaH is ≥95%, and the particle size is 74 μm; the purity of LiH is ≥97%, and the particle size is 74 μm; the purity of Al powder is ≥99%, and the particle size is 74-154 μm TiF 3 Powder purity ≥ 99%, particle size ≤ 154μm. The raw materials and the catalyst are put into the ball mill pot and the balls are added at a ball-to-material ratio of 30:1. Before ball milling, evacuate the ball mill tank to a vacuum degree of 10 -3 bar, then filled with hydrogen with a purity of ≥99.9%, 2.5MPa, and then ball milled at...

Embodiment 3

[0029] Na according to the chemical formula x Li 3-x H 6 Coordination hydride hydrogen storage material, x=2.4, that is to form Na 2.4 Li 0.6 H 6 Coordinated hydrides. Use NaH, LiH and Al powder as raw materials. Choose simple V powder as the catalyst. First calculate the weight ratio of NaH, LiH and Al powder according to NaH: LiH: Al=2.4: 0.6: 1 (molar ratio), and then calculate the doping ratio of V catalyst according to 4mol.% of the total molar weight of (NaH+LiH+Al). Impurities, the average particle size of V powder is about 50 μm, and the purity is >99%. Raw material parameters such as purity and particle size of NaH, LiH and Al are the same as in Example 1. Before ball milling, evacuate the ball mill tank to a vacuum degree of 10 -3 bar, then filled with 3.8MPa hydrogen with a purity greater than 99.99%, and then ball milled at room temperature for 130h to prepare Na 2.4 Li 0.6 H 6 The measured hydrogen storage capacity of the complex hydride is 3.03 wt.%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com