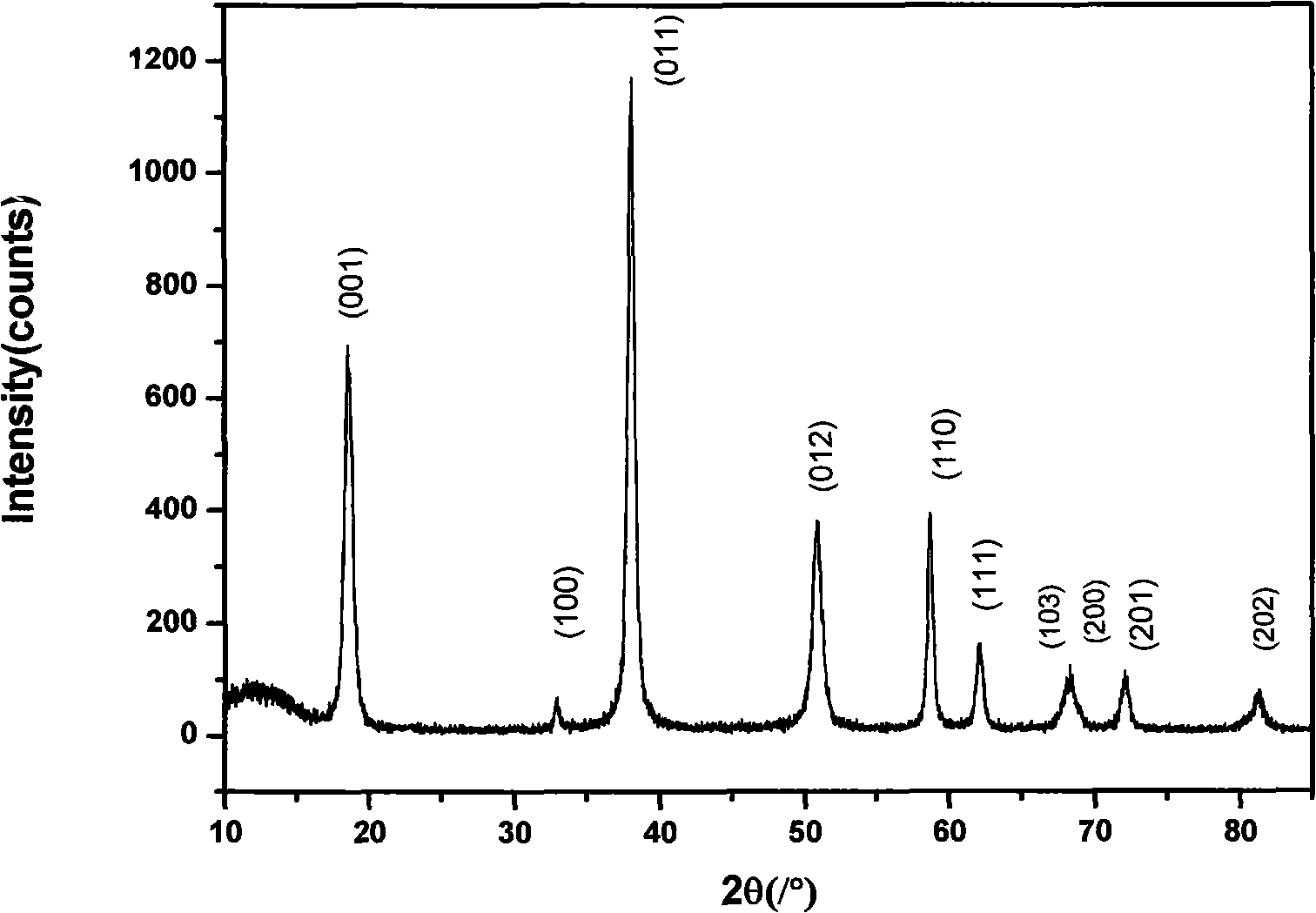

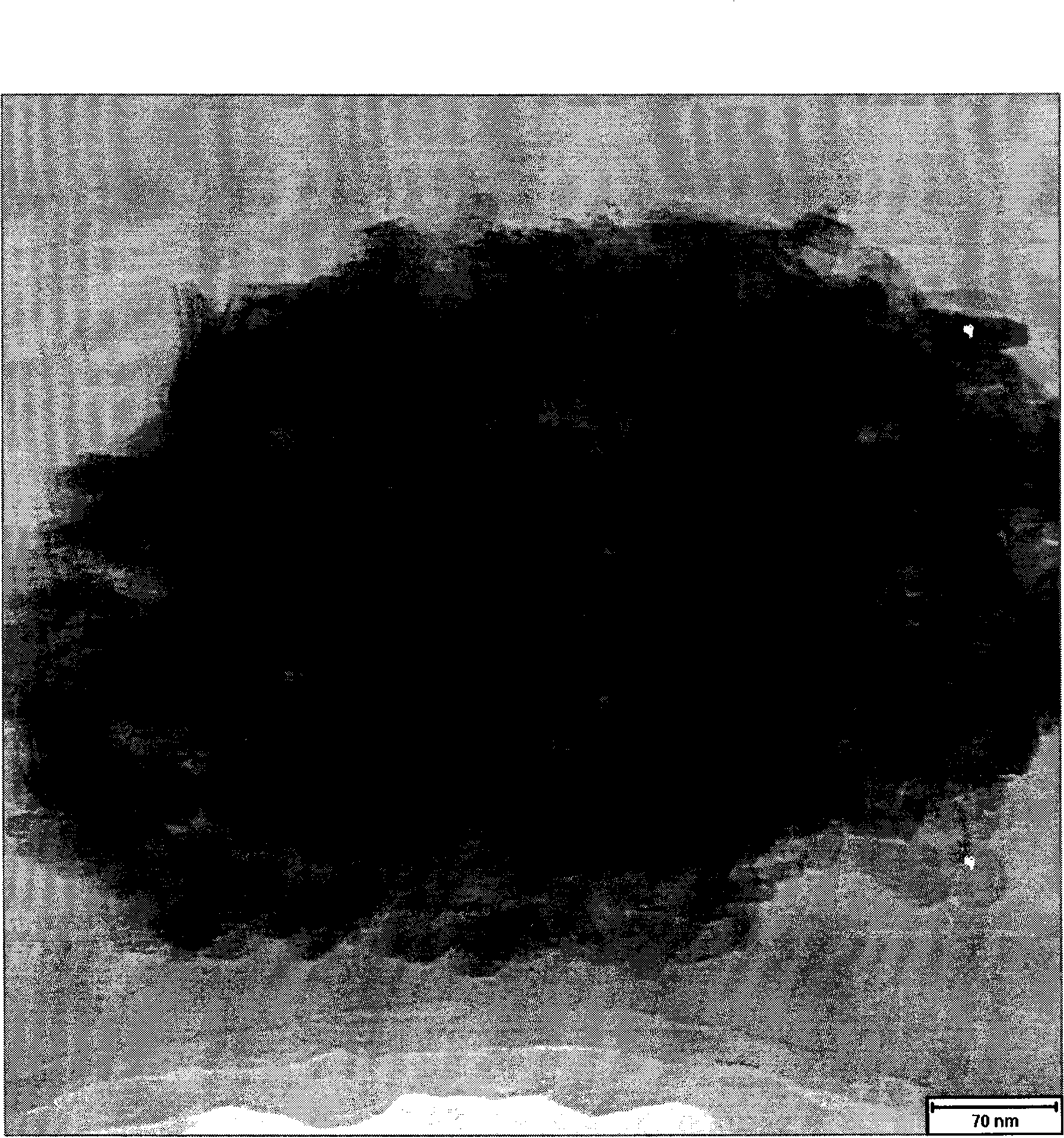

Preparation method of highly pure magnesium hydroxide nanocrystal

A magnesium hydroxide and nanocrystalline technology, applied in the direction of magnesium hydroxide, can solve the problems of poor filtration performance, poor crystallinity, strong volatility of ammonia water in the operating environment, etc., and achieve the effect of facilitating mass production and low autoclave pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of preparation method of high-purity magnesium hydroxide nanocrystal, its preparation method comprises the steps:

[0032] ①. Measure NaOH solution with a concentration of 2.0mol / L at room temperature and place it in a stainless steel container, and mix MgCl with a concentration of 1.0mol / L under constant stirring 2 ·6H 2 The O solution was added in batches and stirred for 20 minutes to make the mixed [OH - ] / 2[Mg 2+ ] molar ratio reaches 1.00;

[0033] ②. Transfer the mixed system into a high-pressure reactor, heat it up to 124°C, keep the pressure at 0.20Mpa, keep it warm for 2 hours, cool it naturally for 22 hours and age it in the reactor;

[0034] ③. Rinse the aged solid-liquid mixture twice on a Buchner funnel lined with medium-speed qualitative filter paper, and filter it with suction; put the filtered product into an oven for drying, drying conditions: 130°C×2hr; cool the product , weighed, and ground to obtain magnesium hydroxide nanocr...

Embodiment 2

[0036] Embodiment 2: a kind of preparation method of high-purity magnesium hydroxide nanocrystal, its preparation method comprises the steps:

[0037] Step 1. used alkali NaOH solution in embodiment 1 is replaced with KOH solution instead;

[0038] The remaining steps of a method for preparing high-purity magnesium hydroxide nanocrystals are the same as in Example 1. The size and purity of the product obtained are also the same as in Example 1.

Embodiment 3

[0039] Embodiment 3: a kind of preparation method of high-purity magnesium hydroxide nanocrystal, its preparation method comprises the steps:

[0040] ①. Measure NaOH solution with a concentration of 7.0mol / L at room temperature and place it in a stainless steel container, and mix MgCl with a concentration of 4.5mol / L under constant stirring 2 ·6H 2 The O solution was added in batches and stirred for 20 minutes to make the mixed [OH - ] / 2[Mg 2+] molar ratio reaches 1.30;

[0041] ②. Transfer the mixed system into a high-pressure reactor, heat up to 135°C, keep the pressure at 0.32Mpa, then keep it warm for 5 hours, cool naturally for 22 hours and age in the reactor;

[0042] ③. Rinse the aged solid-liquid mixture twice on a Buchner funnel lined with medium-speed qualitative filter paper, and filter it with suction; put the filtered product into an oven for drying, drying conditions: 130°C×2hr; cool the product , weighed, and ground to obtain magnesium hydroxide nanocrystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com