Method for preparing manganic manganous oxide nano-material

A technology of manganese trimganese tetraoxide nanometer and manganese acetate, which is applied in the direction of nanostructure manufacturing, manganese oxide/manganese hydroxide, nanotechnology, etc., to achieve the effects of high output, easy control and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

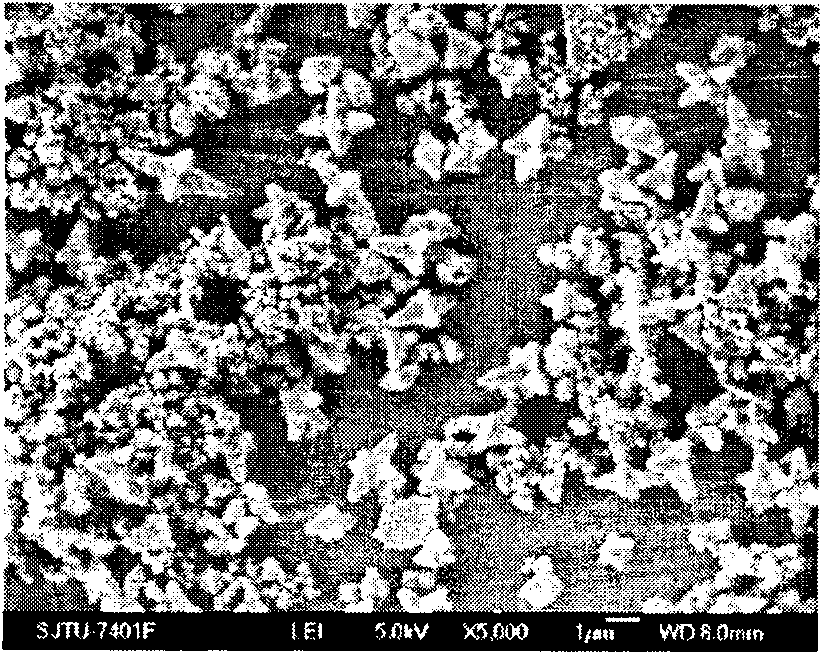

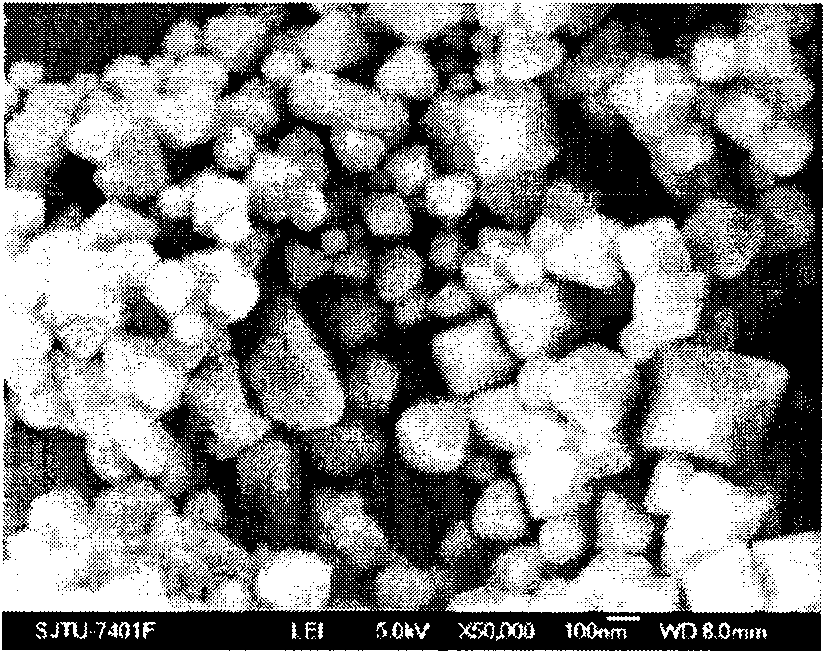

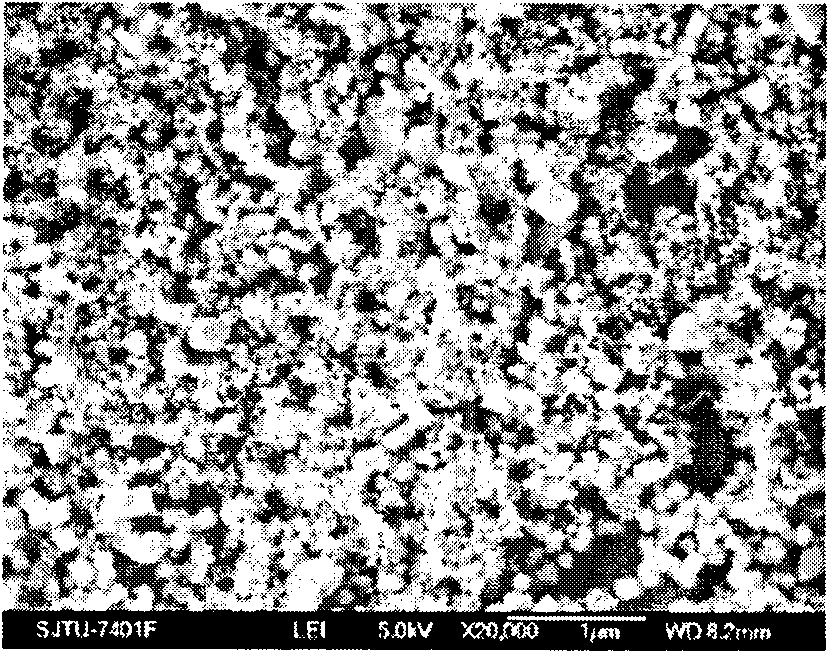

Image

Examples

Embodiment 1

[0022] The first step, inject 10 milliliters of pure water in the beaker of 50 milliliters, dissolve 1 millimole manganese acetate in water and stir to form clear solution, then dissolve 1 millimole sodium sulfate therein and stir to obtain manganese acetate aqueous solution. In addition, 10 ml of pure water was injected into a 50 ml beaker, 4 mmol of manganese acetate was dissolved in water to obtain a clear solution, and 0.4 g of polyvinylpyrrolidone was dissolved therein and stirred to obtain an aqueous solution of polyvinylpyrrolidone.

[0023] The second step is to mix and stir the manganese acetate aqueous solution and the polyvinylpyrrolidone aqueous solution for 30 minutes, then transfer it into a stainless steel autoclave with a polytetrafluoroethylene liner with a volume of 35 ml, and add pure water to 70% to 90% of the volume of the kettle , the kettle was sealed, and put into a high-temperature oven at 180° C. to react for 24 hours.

[0024] The third step is to ul...

Embodiment 2

[0027] The first step, inject 10 milliliters of pure water in the beaker of 50 milliliters, dissolve 1 millimole manganese acetate in water and stir to form a clear solution, then dissolve 1 millimole potassium sulfate therein and stir to obtain manganese acetate aqueous solution. In addition, 10 ml of pure water was injected into a 50 ml beaker, 4 mmol of manganese acetate was dissolved in water to obtain a clear solution, and 0.4 g of polyvinylpyrrolidone was dissolved therein and stirred to obtain an aqueous solution of polyvinylpyrrolidone.

[0028] The second step is to mix and stir the manganese acetate aqueous solution and the polyvinylpyrrolidone aqueous solution for 30 minutes, then transfer it into a stainless steel autoclave with a polytetrafluoroethylene liner with a volume of 35 ml, and add pure water to 70% to 90% of the volume of the kettle , the kettle was sealed, and put into a high-temperature oven at 180° C. to react for 24 hours.

[0029] The third step is ...

Embodiment 3

[0031] The first step, inject 10 milliliters of pure water in the beaker of 50 milliliters, dissolve 1 mmol manganese acetate in water and stir to form clear manganese acetate aqueous solution. In addition, 10 ml of pure water was injected into a 50 ml beaker, 4 mmol of manganese acetate was dissolved in water to obtain a clear solution, and 0.4 g of polyvinylpyrrolidone was dissolved therein and stirred to obtain an aqueous solution of polyvinylpyrrolidone.

[0032] The second step is to mix and stir the manganese acetate aqueous solution and the polyvinylpyrrolidone aqueous solution for 30 minutes, then transfer it into a stainless steel autoclave with a polytetrafluoroethylene liner with a volume of 35 ml, and add pure water to 70% to 90% of the volume of the kettle , the kettle was sealed, and put into a high-temperature oven at 180° C. to react for 24 hours.

[0033] The third step, after natural cooling of the obtained manganese-containing solid salt, ultrasonically disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com