125 DEG C irradiated crosslinking low-smoke and halogen-free flame retardant polyolefin jacket material used for oil platform

A polyolefin sheath, oil platform technology, applied in plastic/resin/wax insulators, organic insulators, conductors, etc., can solve the problems of high cost, large amount of smoke, unfavorable promotion and application, etc. low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The raw material components are as follows:

[0026] Ingredient parts by mass

[0027] EVA 80 parts

[0028] 20 parts of compatibilizer

[0029] Silicone complex 8 parts

[0030] Magnesium hydroxide 40 parts

[0031] Aluminum hydroxide 80 parts

[0032] Antioxidant 1010 4 parts

[0033] 1 part magnesium stearate

[0034] Polyethylene wax 0.2 parts

[0035] Triallyl isocyanurate 3 parts

[0036] Preparation method: The above raw material components are mixed by a plastic high mixer, plasticized and granulated by a twin-screw extrusion granulator and dried to obtain the product.

Embodiment 2

[0038] The raw material components are as follows:

[0039] Ingredient parts by mass

[0040] EVA 80 parts

[0041] 20 parts of compatibilizer

[0042] Silicone complex 8 parts

[0043] Magnesium hydroxide 20 parts

[0044] Aluminum hydroxide 100 parts

[0045] Antioxidant 1010 4 parts

[0046] 1 part magnesium stearate

[0047] Polyethylene wax 0.2 parts

[0048] Triallyl isocyanurate 3 parts

[0049] The preparation method is the same as in Example 1.

Embodiment 3

[0051] The raw material components are as follows:

[0052] Ingredient parts by mass

[0053] EVA 70 parts

[0054] 30 parts of compatibilizer

[0055] Silicone complex 8 parts

[0056] Magnesium hydroxide 40 parts

[0057] Aluminum hydroxide 80 parts

[0058] Antioxidant 1010 4 parts

[0059] 1 part magnesium stearate

[0060] Polyethylene wax 0.2 parts

[0061] Triallyl isocyanurate 3 parts

[0062] The preparation method is the same as in Example 1.

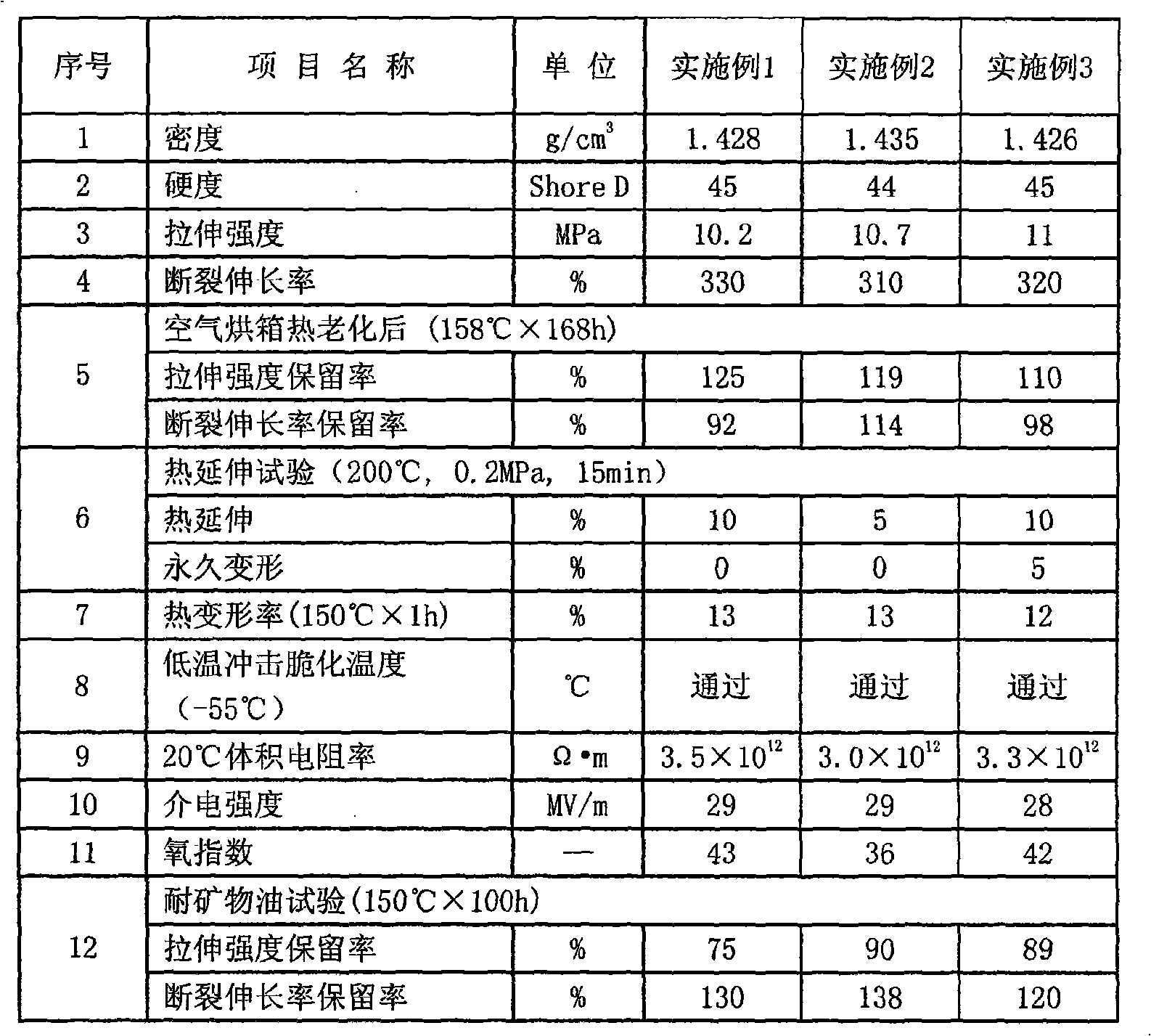

[0063] The technical parameters of the 125°C irradiation cross-linked low-smoke halogen-free flame-retardant polyolefin sheath material for oil platforms prepared in each embodiment are shown in Table 1.

[0064] Table 1.

[0065]

[0066] It can be seen from the indicators in Table 1 that the 125°C irradiation crosslinked low-smoke halogen-free flame-retardant polyolefin sheathing material for oil platforms of the present invention has excellent high-strength mechanical properties, aging resistance, oil resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com