Method for preparing nitride red fluorescent powder for white light LED

A technology of nitride phosphors and red phosphors, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of complex circuit design, high cost, immature technology, etc., and achieve good chemical and thermal stability , strong absorption and high heat quenching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

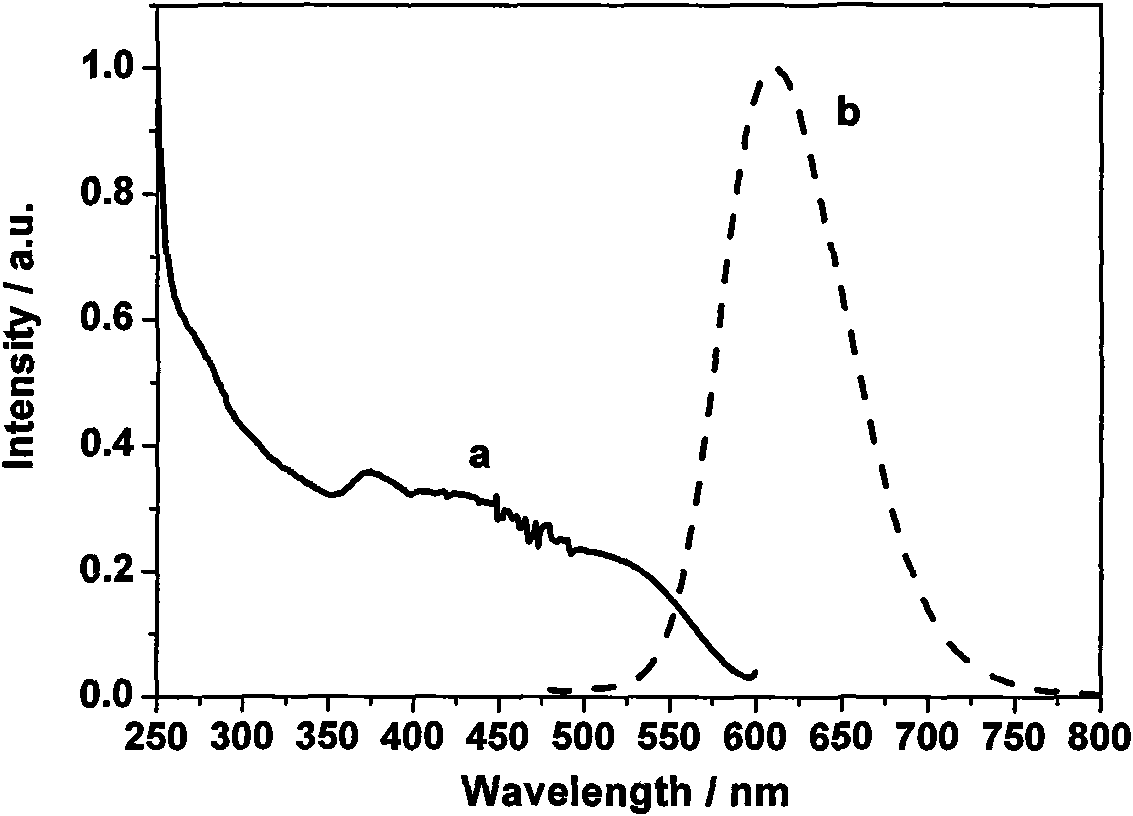

Image

Examples

Embodiment 1

[0010] Embodiment 1: A kind of preparation method of nitride red fluorescent powder for white light LED, this method follows the following steps: 1.98 moles of compound A, 0.02 moles of EuN 0.95 and 1.67 moles of amorphous Si 3 N 4 Mix well to get a mixture, in N 2 and H 2 After the mixture was fired at 1350 ° C for 15 hours in a mixed atmosphere with a volume ratio of 9:1, it was cooled to room temperature and ground for the first time to obtain the first grinding product. 2 and H 2 In a mixed atmosphere with a volume ratio of 9:1, burn the first grinding product at 1450°C for 13 hours, take it out after cooling to room temperature, and perform the second grinding to obtain the second grinding product. The second grinding The product passes through a 150-mesh sieve to obtain a nitride red phosphor powder for white light LEDs; the compound A is SrN x , x=0.65 in compound A.

Embodiment 2

[0011] Embodiment 2: A kind of preparation method of nitride red fluorescent powder for white light LED, this method follows the following steps: 1.995 moles of compound A, 0.005 moles of EuN 0.95 and 1.67 moles of amorphous Si 3 N 4 Mix well to get a mixture, in N 2 and H 2 After the mixture was fired at 1350 ° C for 15 hours in a mixed atmosphere with a volume ratio of 9:1, it was cooled to room temperature and ground for the first time to obtain the first grinding product. 2 and H 2 In a mixed atmosphere with a volume ratio of 9:1, burn the first grinding product at 1450°C for 13 hours, take it out after cooling to room temperature, and perform the second grinding to obtain the second grinding product. The second grinding The product passes through a 150-mesh sieve to obtain a nitride red phosphor powder for white light LEDs; the compound A is SrN x , x=0.65 in compound A.

Embodiment 3

[0012] Embodiment 3: A kind of preparation method of nitride red fluorescent powder for white light LED, this method follows the following steps: 1.999 moles of compound A, 0.001 moles of EuN 0.95 and 1.67 moles of amorphous Si 3 N 4 Mix well to get a mixture, in N 2 and H 2 After the mixture was fired at 1350 ° C for 15 hours in a mixed atmosphere with a volume ratio of 9:1, it was cooled to room temperature and ground for the first time to obtain the first grinding product. 2 and H 2 In a mixed atmosphere with a volume ratio of 9:1, burn the first grinding product at 1450°C for 13 hours, take it out after cooling to room temperature, and perform the second grinding to obtain the second grinding product. The second grinding The product passes through a 150-mesh sieve to obtain a nitride red phosphor powder for white light LEDs; the compound A is SrN x , x=0.65 in compound A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com