Micro-stress shelter pile foundation strengthening method

A stress isolation and pile foundation technology, applied in the direction of foundation structure engineering, foundation structure repair, soil protection, etc., can solve the problems of inability to erect large-scale pile-forming equipment, reduction of friction resistance of original bridge piles, and low clearance of urban bridges. Achieve the effect of improving physical and mechanical properties, increasing bearing capacity and deformation modulus, and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

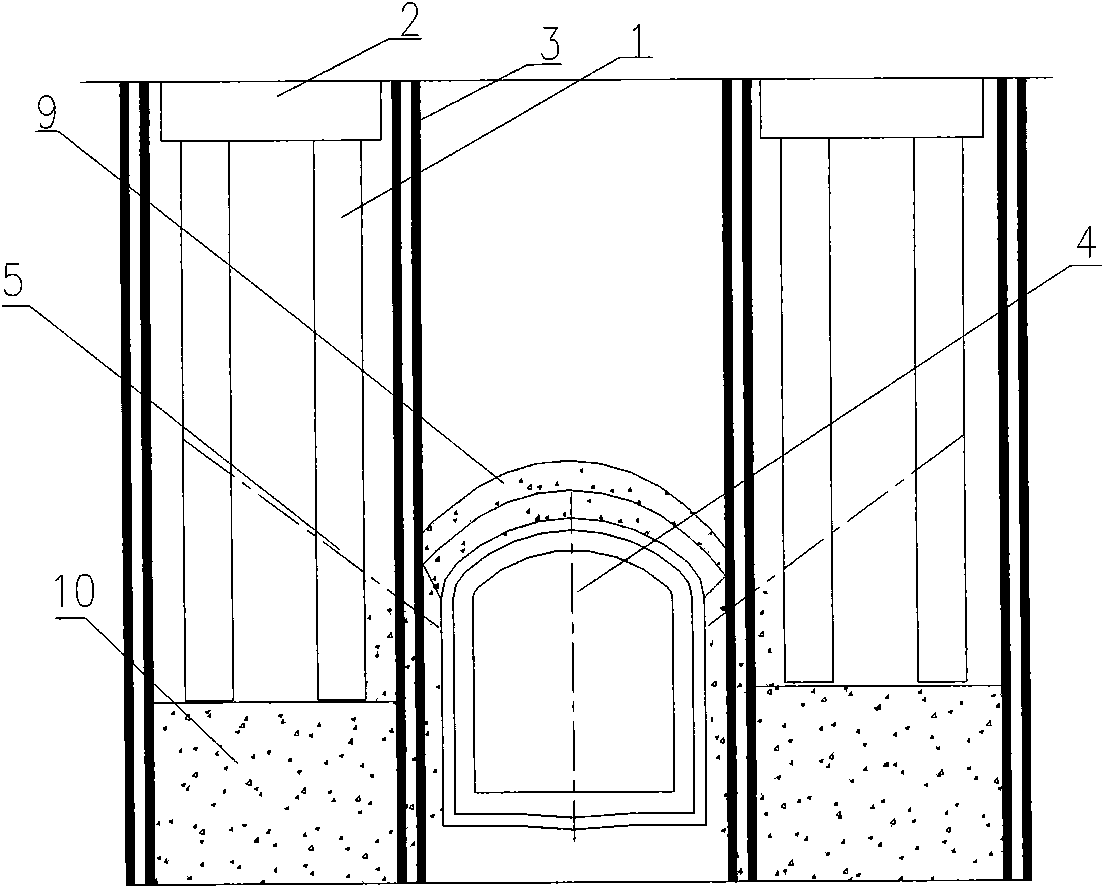

[0026] The present invention will be further described below in conjunction with accompanying drawing.

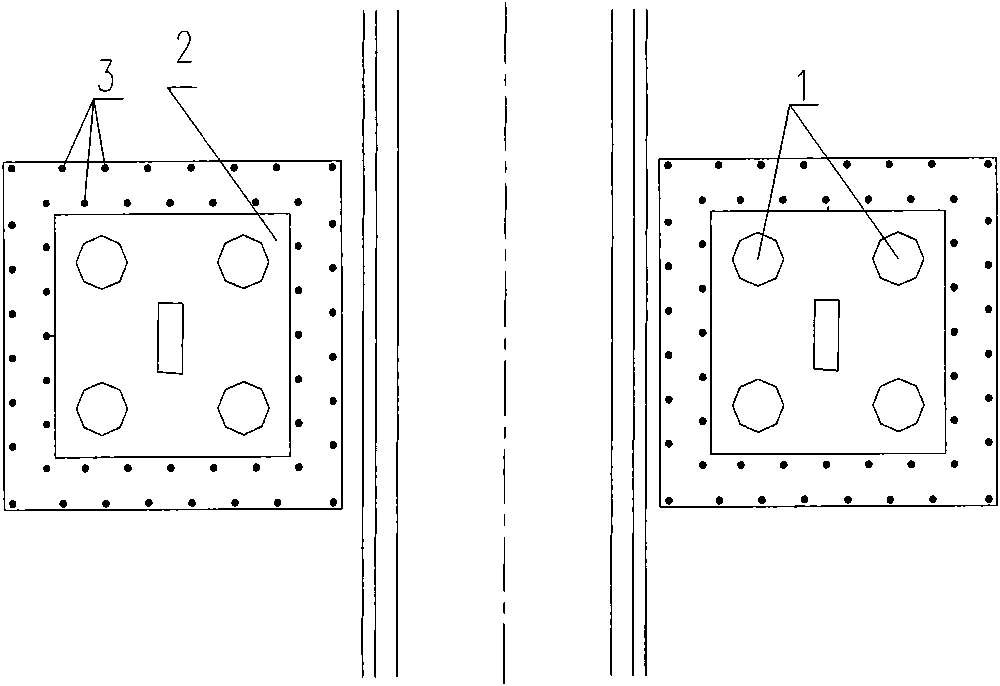

[0027] exist figure 1 Among them, the miniature stress isolation piles 3 are set up around the bridge pile foundation 1 and the cap 2 from the ground, and the miniature stress isolation piles can be arranged in a single row or in multiple rows.

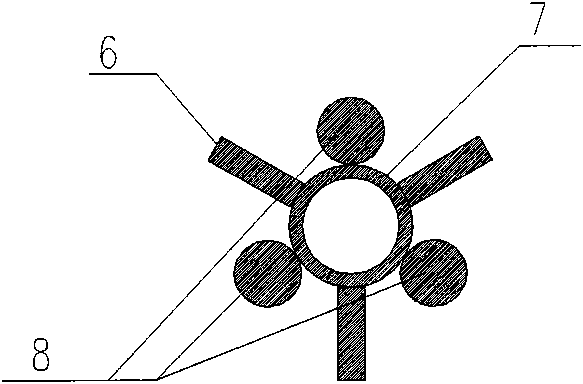

[0028] exist figure 2 Among them, the rod body of each micro-stress isolation pile 3 is composed of a positioning support 6, an isolation inner ring 7 and 2-5 longitudinal threaded steel bars 8.

[0029] In the specific implementation, the casing pipe of the dry method is used to follow up the equipment to form holes, and the simple support frame is used for hoisting, and the manual fit is put in place. After the rod body is in place, pull out the drilling casing to prepare for grouting.

[0030] exist image 3 Among them, the pile diameter of micro stress isolation pile 3 is generally 0.15-0.25m, and the spacing and row spaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com