Engine waste heat recovery system based on organic rankine cycle

A technology of engine waste heat and Rankine cycle, applied in the direction of machine/engine, engine operation, engine components, etc., can solve problems such as system optimization and engine bipolar supercharging bipolar intercooler, etc. The problem of limited application of aluminum material, high energy recovery efficiency, and the effect of reducing environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

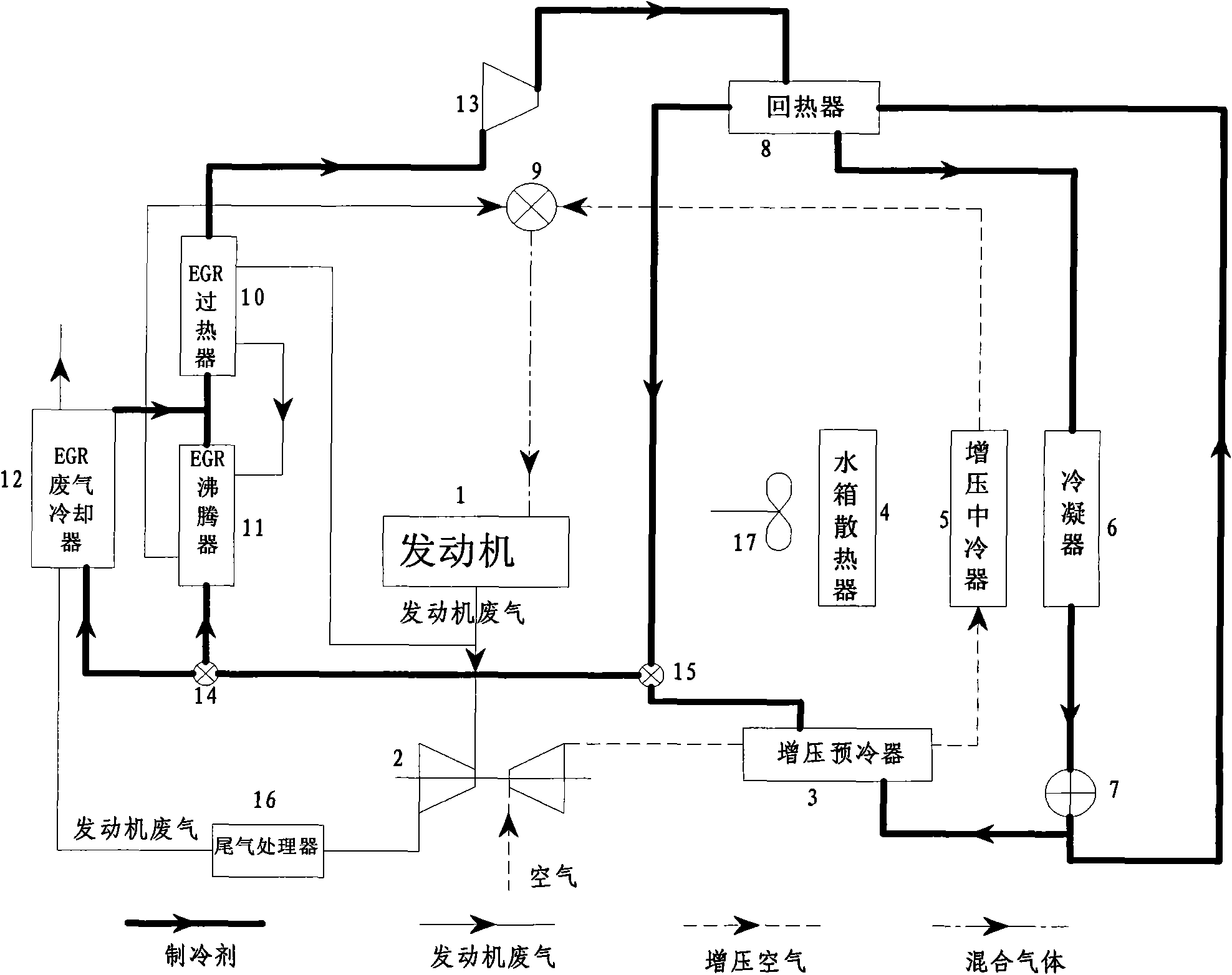

[0017] Such as figure 1 As shown, the engine waste heat recovery system of the present invention mainly includes: the main heat source engine 1 of the system, especially a heavy-duty engine; used as a working medium refrigerant R245fa and an engine exhaust treatment device as a heating heat source, an EGR superheater 10, and an EGR boiler 11. Exhaust gas cooler 12; booster precooler 3 used as a heater for the working medium refrigerant R245fa, and a regenerator 8 for the refrigerant circuit; a power pump 7 and various A variety of connecting pipelines and valves, such as three-way control valve 14, three-way valve 15; turbine generator 13 used for energy recovery; condenser 6 to complete the transformation of refrigerant from gaseous state to liquid; pipelines and valves for engine exhaust , such as the EGR valve 9; and the front-end module of the engine, which mainly includes a suction fan 17, a supercharged intercooler 5, a water tank radiator 4, and the like.

[0018] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com