Porous-medium gas hot water heater

A technology of gas water heaters and porous media, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of insufficient combustion intensity and heat exchange intensity, complex structure, large volume, etc., and achieve favorable heat Return transmission, uniform temperature distribution, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

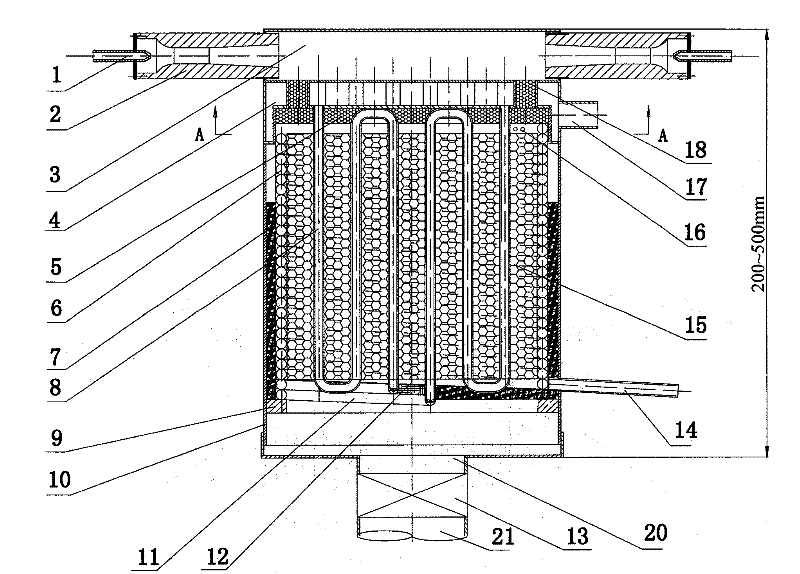

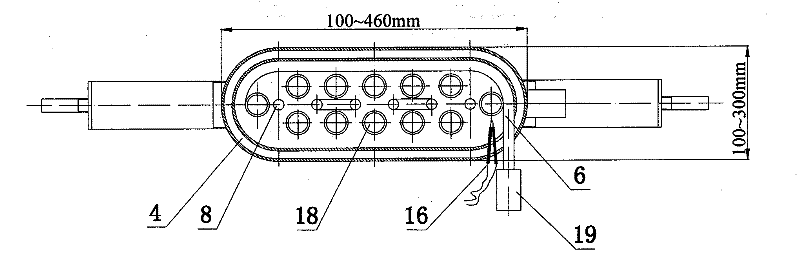

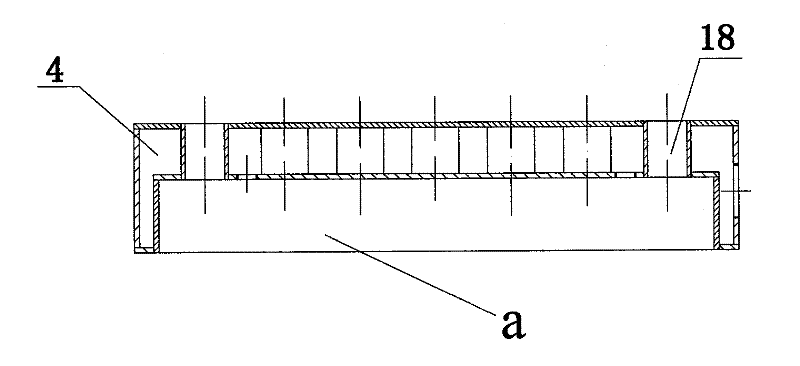

[0038] The structure and shape of this embodiment are shown in Figure 1~4 .

[0039] In the porous medium gas water heater of this embodiment, the width of the cylinder surrounded by the spiral heat exchange tubes 6 is 150mm, the length is 225mm, and the height is 225mm; The center distance of the tempering channel 18 is 30mm; the width of the water heater body is 150mm, the length is 280mm, and the height is 350mm; The cross-section of the sleeve 4, the spiral heat exchange tube 6 and the outer sleeve 10 is oblong, and the upper part of the outer sleeve 10 corresponding to the combustion chamber has 7 rows of vent holes, each with a total of 8 1mm wide holes. Gap, the size of the gap between the small-pore porous medium material 5 and the large-pore porous medium material 15 is 5 mm, and there are 12 anti-temper passages 18 connected up and down in the middle of the water-cooling sleeve 4, and the spiral heat exchange The width of the small gap left at the upper 1 / 3 of the...

Embodiment 2

[0041] Except for the following parts, others are the same as in Example 1.

[0042] In the porous medium gas water heater of this embodiment, the width of the cylinder surrounded by the spiral heat exchange tubes 6 is 40mm, the length is 50mm, and the height is 150mm; The center distance of the tempering channel 18 is 20mm; the width of the water heater body is 100mm, the length is 100mm, and the height is 200mm; The cross-section of the sleeve 4, the spiral heat exchange tube 6 and the outer sleeve 10 is circular, and the air holes provided on the upper part of the outer sleeve 10 corresponding to the combustion chamber are 3 rows of 4 slits with a width of 1 mm each. The size of the gap between the small-pore porous medium material 5 and the large-pore porous medium material 15 is 4 mm, and there is one anti-temper passage 18 connected up and down in the middle of the water-cooling sleeve 4, and the spiral heat exchange tube 6 The width of the small slit left at the upper ...

Embodiment 3

[0044] Except for the following parts, others are the same as in Example 1.

[0045] In the porous medium gas water heater of this embodiment, the width of the cylinder surrounded by the spiral heat exchange tubes 6 is 250mm, the length is 400mm, and the height is 300mm; The center distance of the tempering channel 18 is 40mm; the width of the water heater body is 300mm, the length is 460mm, and the height is 500mm; The cross-section of the sleeve 4, the spiral heat exchange tube 6 and the outer sleeve 10 is elliptical, and the air holes provided on the upper part of the outer sleeve 10 corresponding to the combustion chamber are 5 rows of 16 slits with a width of 2 mm each. The size of the gap between the small-pore porous medium material 5 and the large-pore porous medium material 15 is 6mm, and there are 42 anti-temper passages 18 connected up and down in the middle of the water-cooling sleeve 4, and the spiral heat exchange tube 6 The width of the small slit left at the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com