Transparent conducting film and writing-resistance high-penetrability resistance-type touching control panel using same

A transparent conductive film, touch panel technology, applied in conductive layers on insulating carriers, electrical digital data processing, input/output process of data processing, etc. , to achieve the effect of improving optical transmittance, improving writing resistance, and increasing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

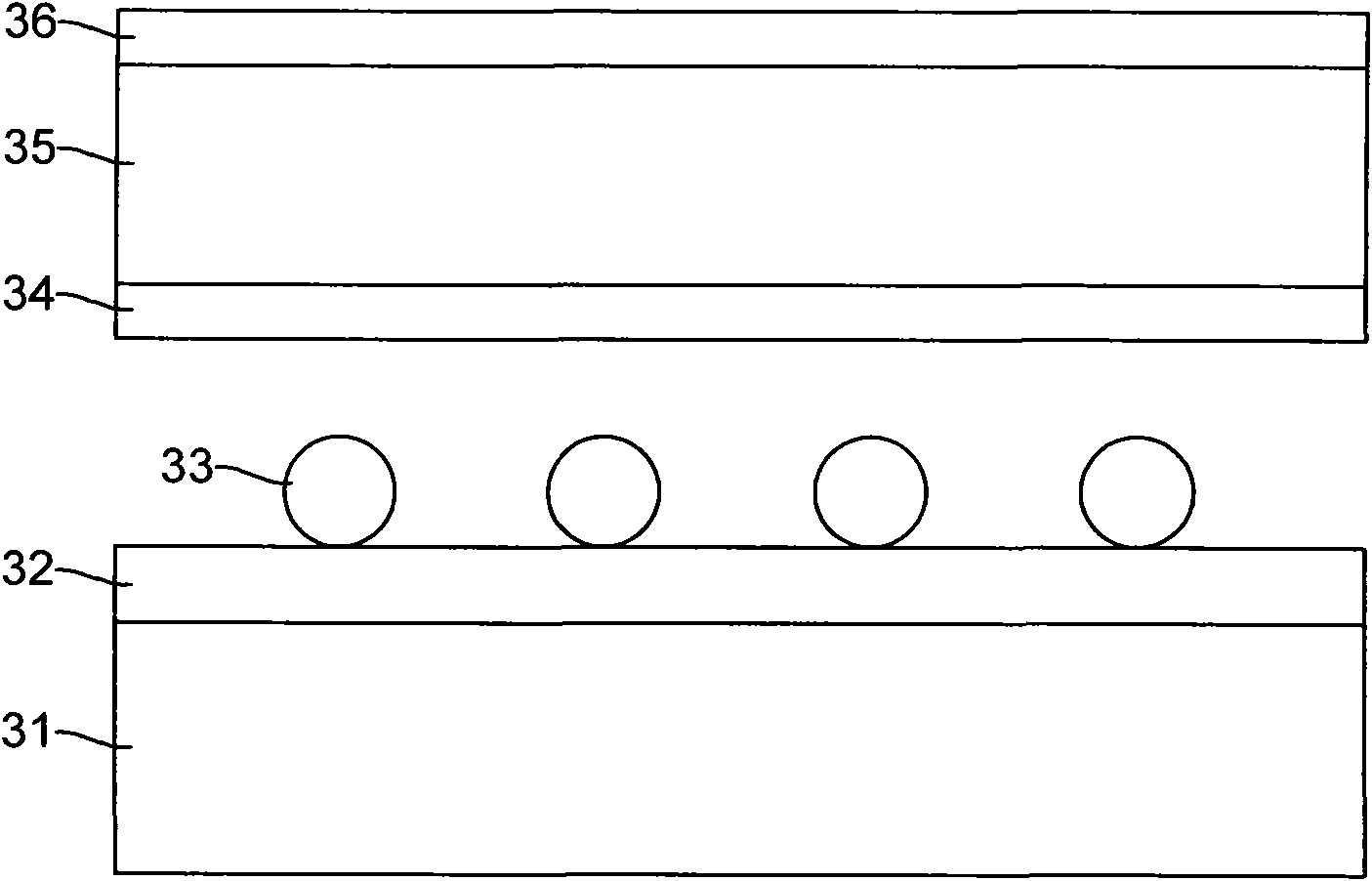

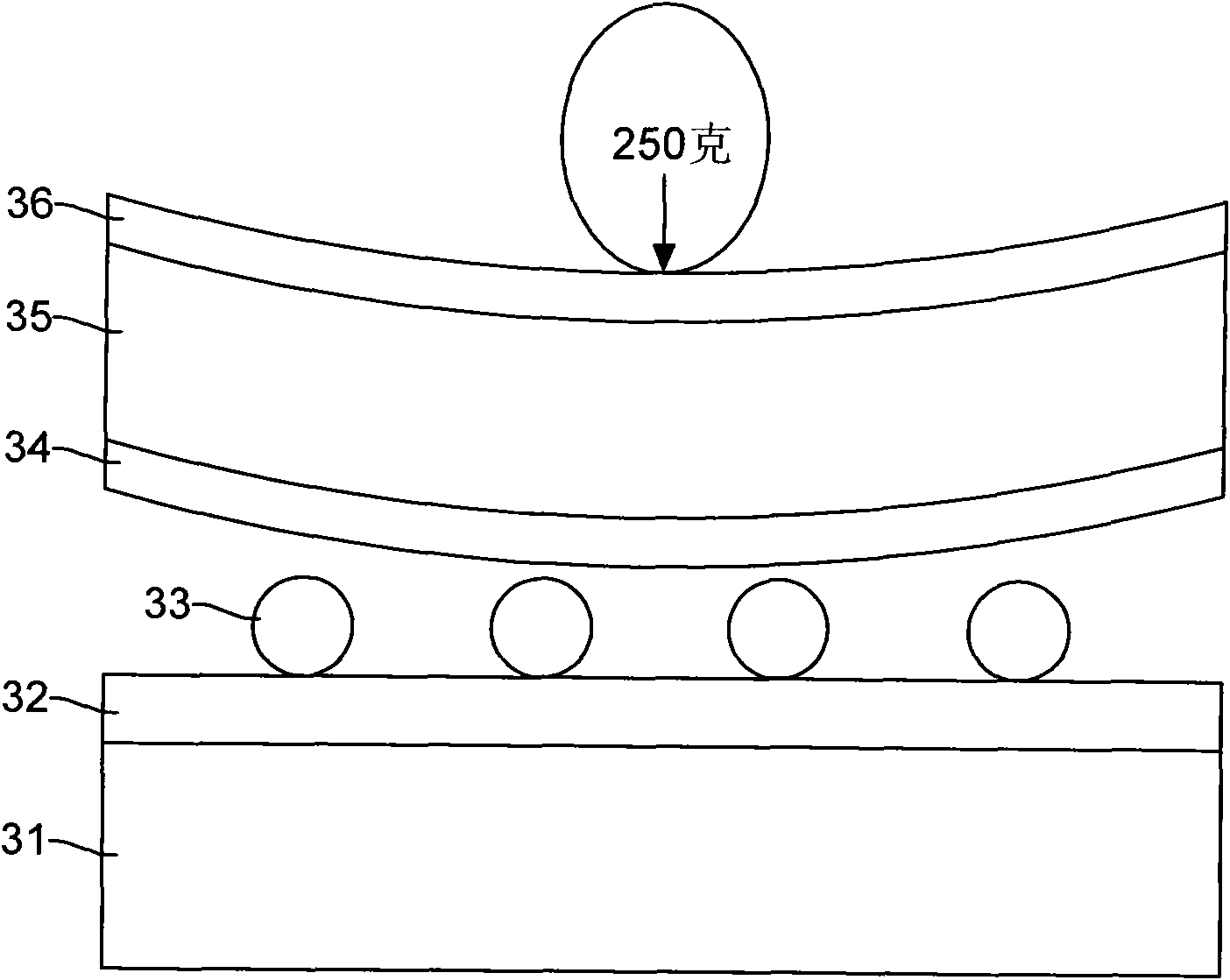

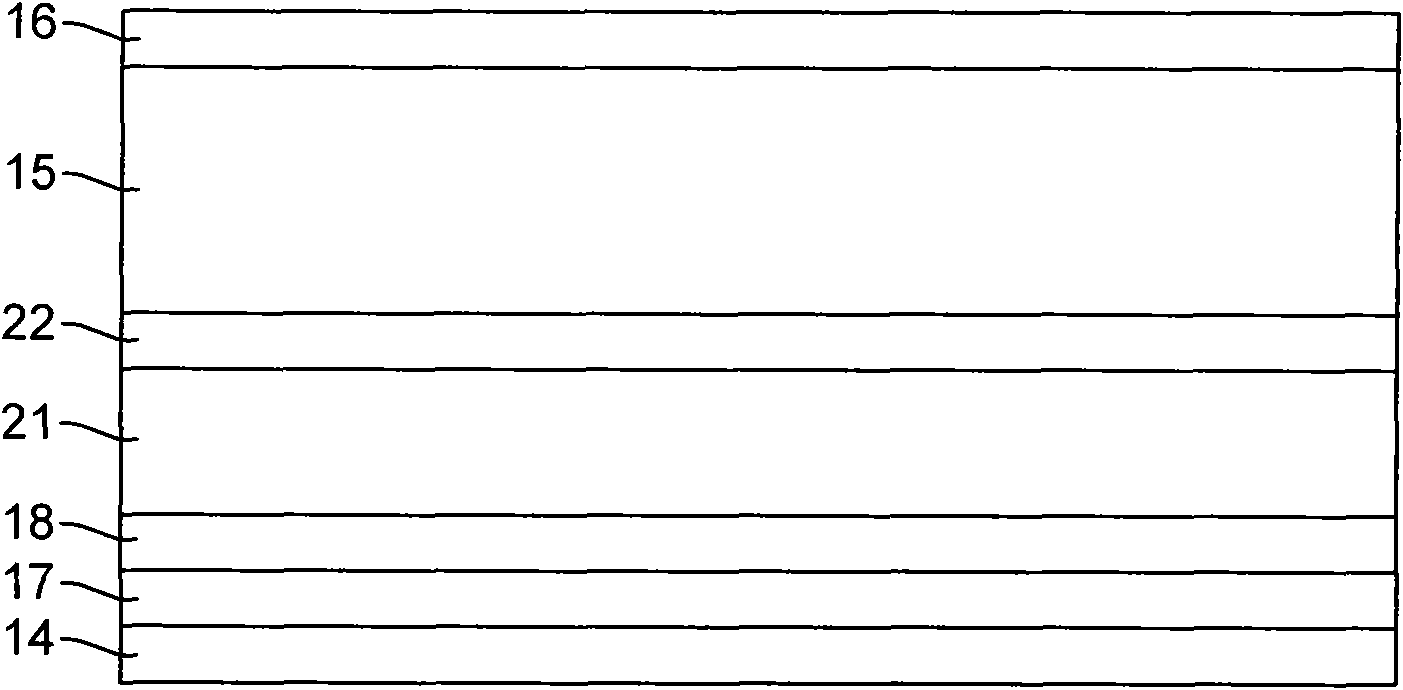

[0039] The design of the conductive film with high optical transmittance is described below. Generally, the transparent conductive film used in the touch panel is composed of a thin film layer of PET and ITO plated on it, that is, in figure 1 Among them, the second base material is PET (polyethylene terephthalate, Polyethylene Terephthalate, PET), and the second conductive layer is an ITO layer, the design of this kind of transparent conductive film, its anti-reflection effect is not good, even By adjusting the thickness of the ITO film layer, the room for improving the overall optical transmittance is very limited. However, by means of optical design, the multilayer film structure can be designed on the existing ITO-PET structure, so that the optical properties can be greatly improved. For example, if image 3 As shown, first on the PET substrate (as the second substrate 21 of the accompanying drawing), a high-refractive-index material (ie, the first dielectric layer 18, who...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com