Preparation method of positive electrode post of lithium battery

A positive pole, lithium battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as failure to achieve high-capacity lithium battery performance indicators, reduced lithium battery positive conductivity, and low lithium battery discharge capacity. , to achieve the effect of being beneficial to adsorption and ion exchange, beneficial to utilization, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

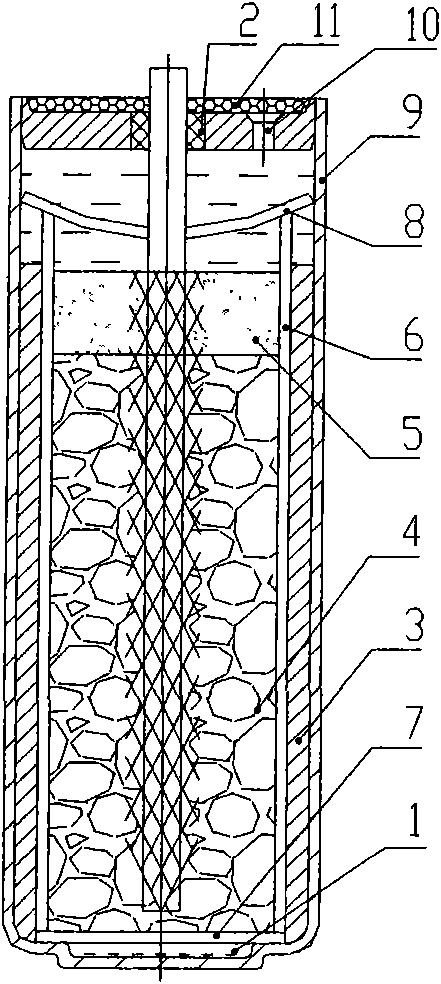

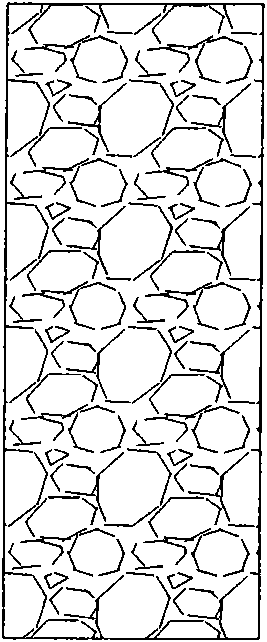

[0026] like figure 1 The shown lithium battery with the lithium battery positive pole prepared by the method of the present invention includes electrolyte 1, cover group 2, lithium negative pole 3, lithium battery positive pole 4, positive electrode cover sheet 5, side diaphragm 6, bottom diaphragm 7, Upper diaphragm 8, steel shell 9, sealing nail 10, epoxy resin 11. Among them, the positive pole of the lithium battery is as figure 2 Shown, the preparation method of lithium battery positive pole comprises the following steps:

[0027] Step (1), mixing and stirring the solid raw material and the liquid raw material in proportion to make the positive electrode raw material; the specific method is:

[0028] Mix the powdery solid raw materials, the solid raw materials include: 5300g powdery acetylene black, 380g copper powder;

[0029] Add liquid raw materials and mix and stir. The liquid raw materials include: 35000ml of distilled water, 1000ml of isopropanol, and 320ml of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com