The production of carbon black, components of hydrocarbon fuels and a raw material for the chemical industry from rubber-containing waste

A chemical industry, hydrocarbon fuel technology, applied in the field of chemical industry, can solve the problems affecting the degree of clean IC, reactor separation area and weight increase, unwanted side reaction effects, etc., to achieve the effect of preventing compaction and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

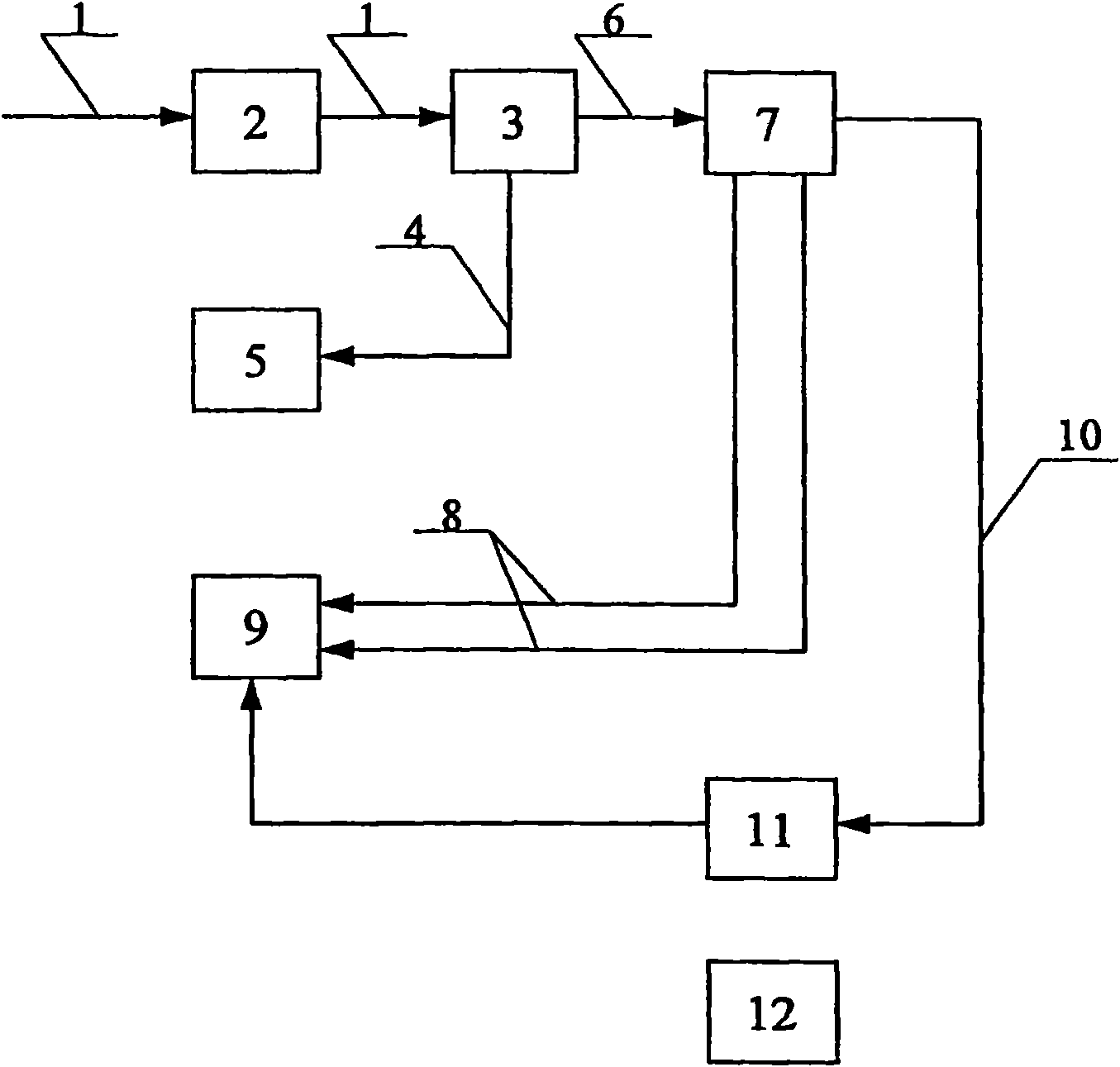

[0048] figure 1 The meaning of the numbers in the middle:

[0049] 1- Contains rubber raw materials;

[0050] 2- Areas for receiving, storing and preparing raw materials;

[0051] 3 - the area for grinding the raw material and separating the fragments after grinding;

[0052] 4- Metal fragments after grinding;

[0053] 5- Areas for storage, pressing, packaging and delivery of commercial products;

[0054] 6 - Rubber crumbs;

[0055] 7- Equipment for the pyrolysis of rubber crumbs;

[0056] 8 - liquid pyrolysis products;

[0057] 9 - storage tank;

[0058] 10 - industrial carbon (IC);

[0059] 11 - Areas for rectification of industrial charcoal;

[0060] 12- General equipment and facilities.

[0061]Rubber-containing raw material 1 including waste tires, cables, rubber goods production waste, household waste, etc. enters an area 2 for receiving, storing and preparing the raw material, and then enters an area 3 for grinding the raw material and separating the pieces af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com