Split type reaming bit for large-diameter raising-boring and assembly method thereof

A reaming bit, large-diameter technology, used in drill bits, drilling equipment, drill pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

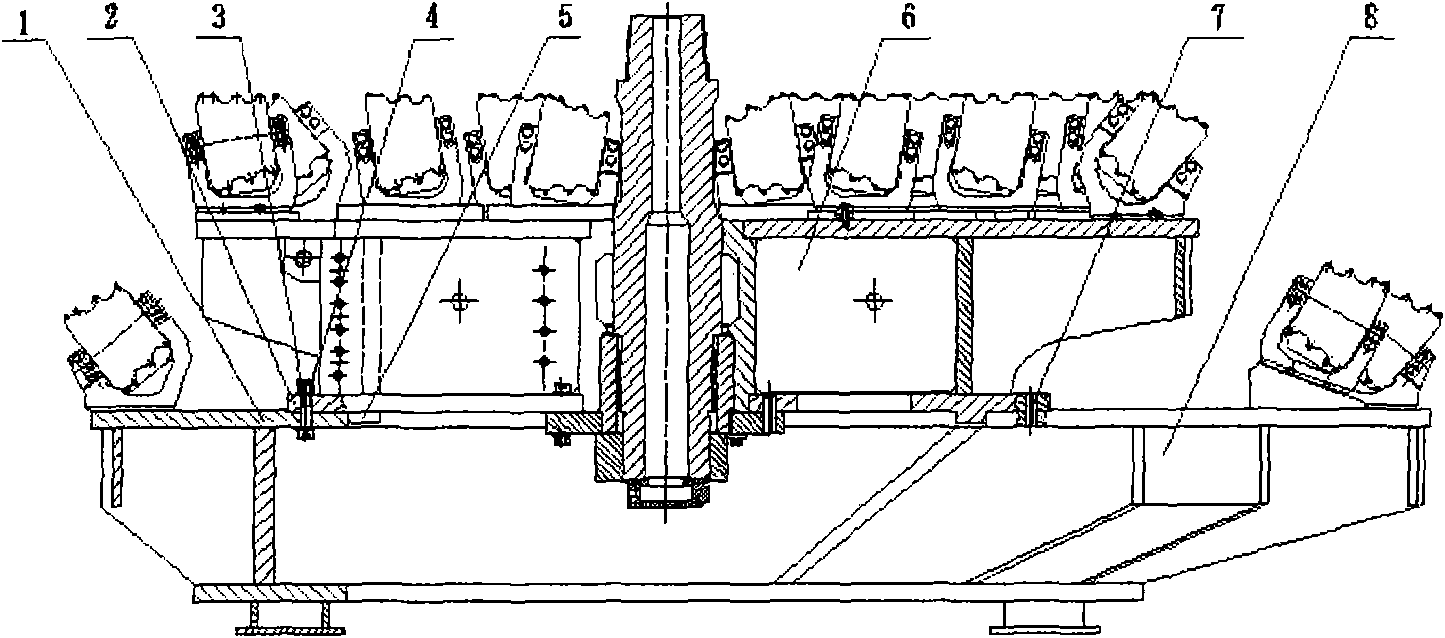

[0014] Such as figure 1 Shown, the present invention is that the first-stage reaming bit body 6 of 3.5m by the reaming diameter that is positioned at the upper part cooperates with the second-stage reaming drill extension part 8 that the reaming diameter is 5.0m through its lower branch, The upper panel 1 of the expansion part of the second-stage reaming drill is connected with the lower panel 2 of the first-stage reaming drill with bolts 3, lock nuts 4 and positioning pins 7 to form the overall structure of the large-diameter reaming drill, which constitutes The "tower" structure formed by the first stage reaming drill 6 and the second stage reaming drill positioned at its lower part.

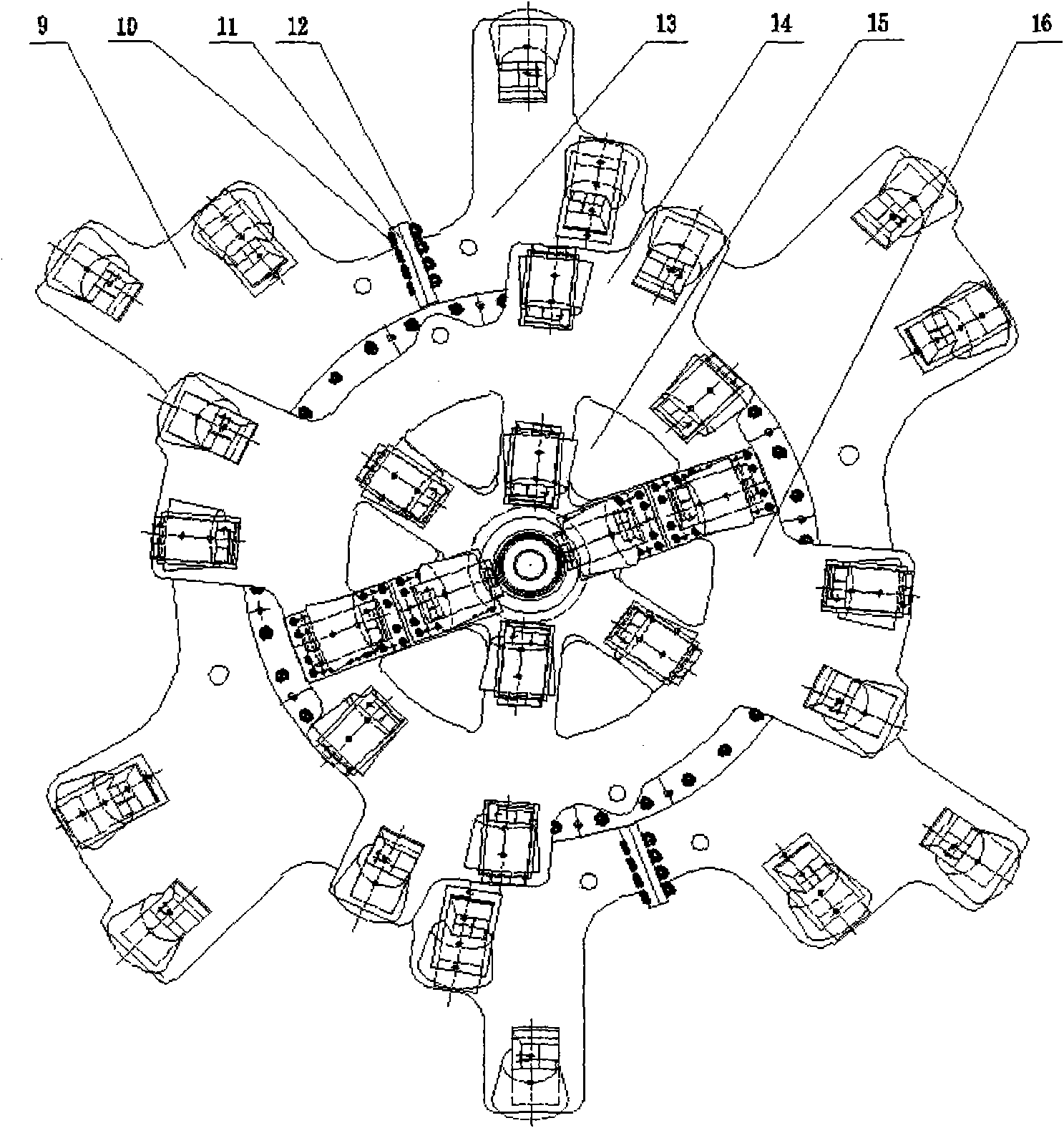

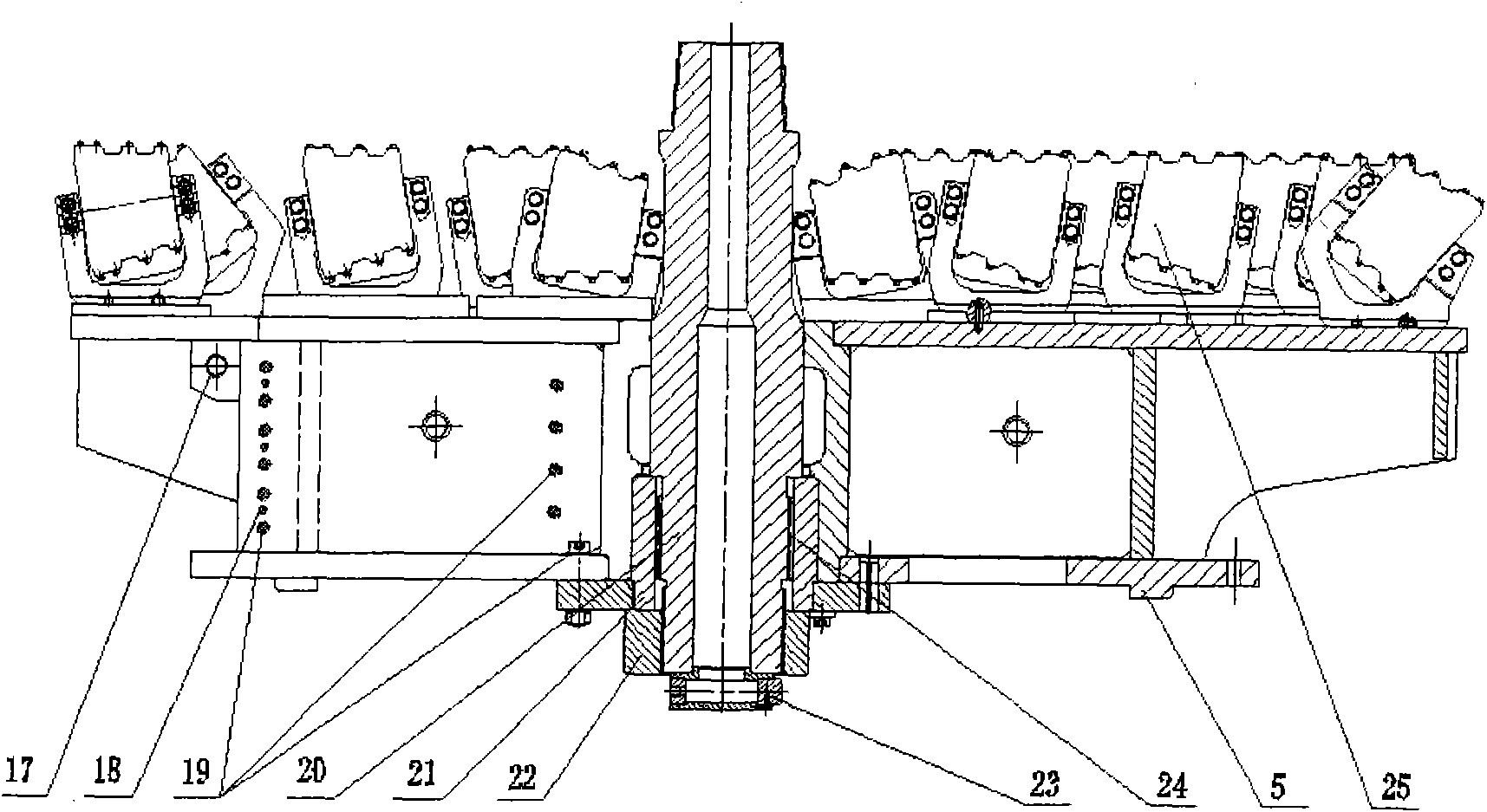

[0015] refer to Figure 2 to Figure 4 , wherein the upper first-stage reaming bit body 6 is divided into left and right halves 14, 16, and the left and right halves 14 and 16 pass through longitudinal positioning pins 18, bolts 19 and transverse connecting bolts 27 and positioning The pins 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com