Method for measuring diameter and straightness accuracy parameters of seamless round steel pipe

A technology for parameter measurement and straightness, applied in measuring devices, instruments, optical devices, etc., can solve problems such as increasing the difficulty of system installation and debugging, improve production efficiency and product quality, simplify adjustments, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

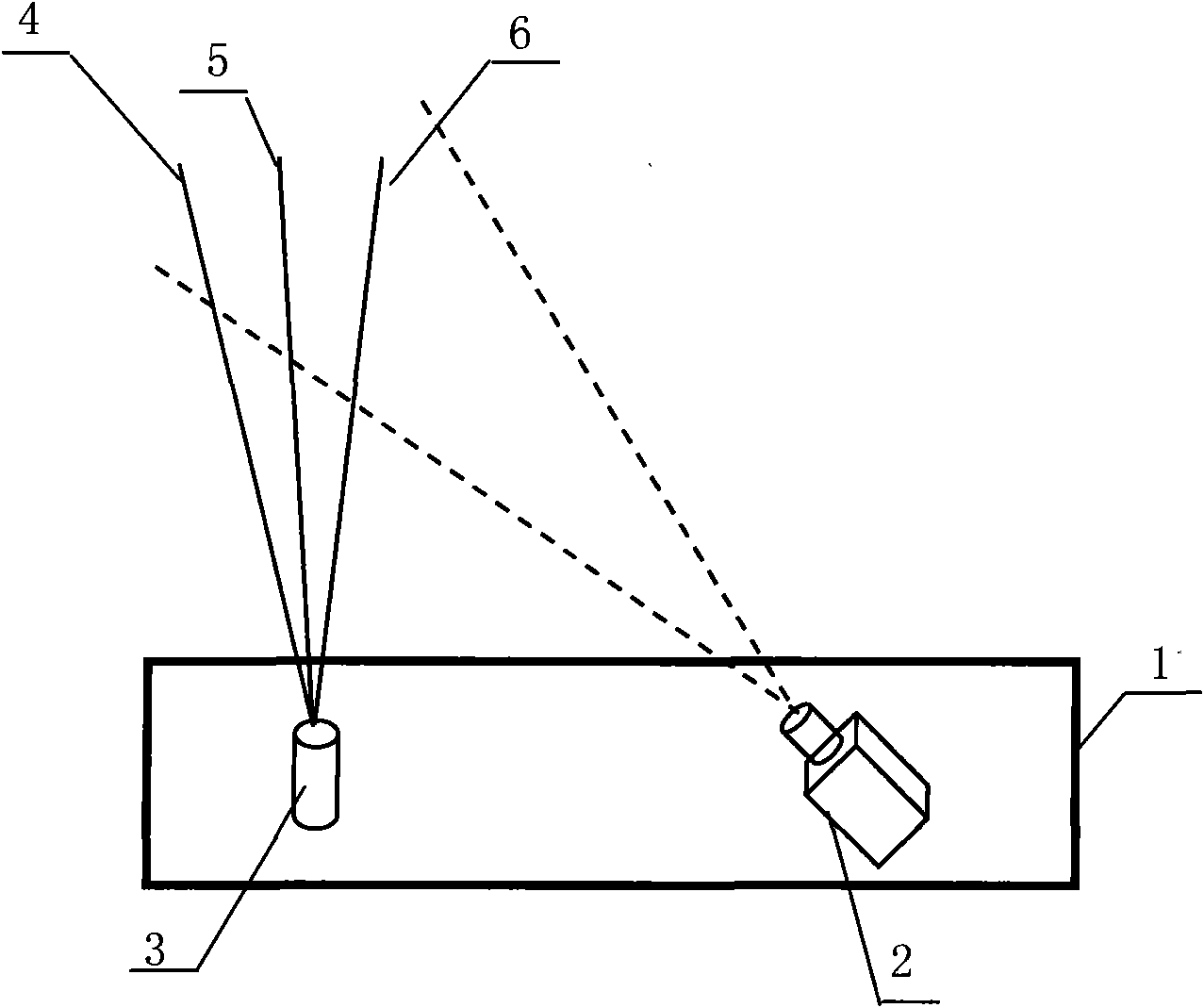

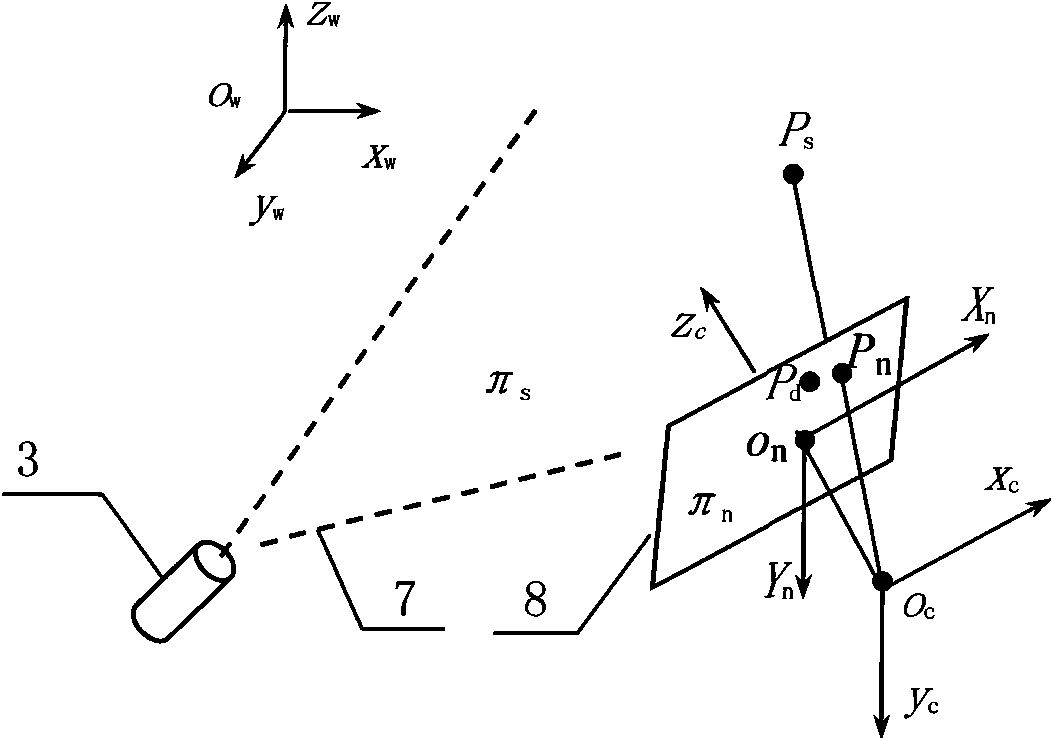

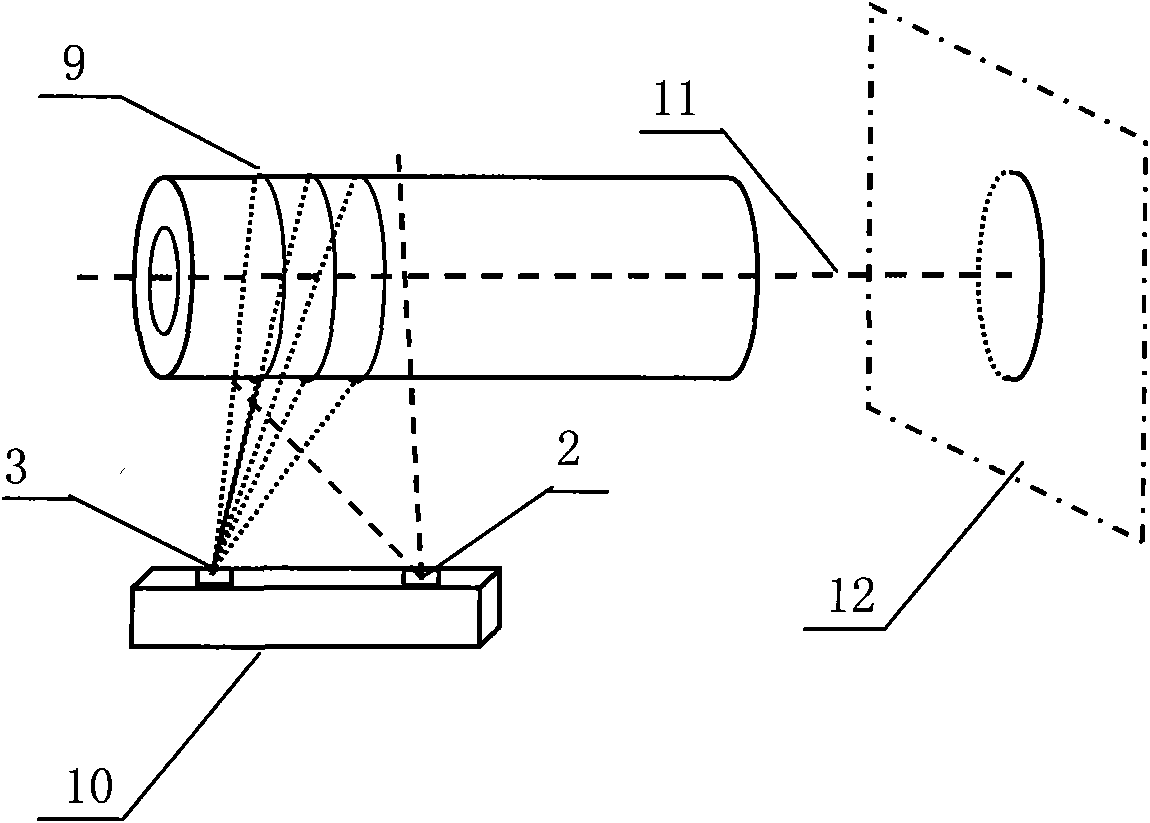

[0034] A method for measuring the diameter and straightness parameters of a seamless circular steel pipe of the present invention is to install a multi-line structured light vision sensor at a suitable position (refer to the working distance of the sensor) of the seamless circular steel pipe to be measured, and the structure of laser projection in the sensor The central axis of the light plane and the seamless circular steel pipe is not required to be strictly vertical, and the installation of the sensor has no strict pose requirements; the measurement of the straightness of the seamless circular steel pipe and the dynamic construction of the virtual central axis: the multi-line structured light vision sensor is used to realize it simultaneously The measurement of three-dimensional data of multiple different sections of seamless circular steel pipes, fitting the space section ellipse through the three-dimensional data measured by different sections, and determining the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com