Wastewater treatment

A waste water and horizontal technology, applied in food industry waste water treatment, water treatment parameter control, biological water/sewage treatment, etc., can solve the problems of sludge settling degradation, interference stability and reliable EBRP method development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0164] Example 1-Treatment of slaughterhouse wastewater, discharged into the drain

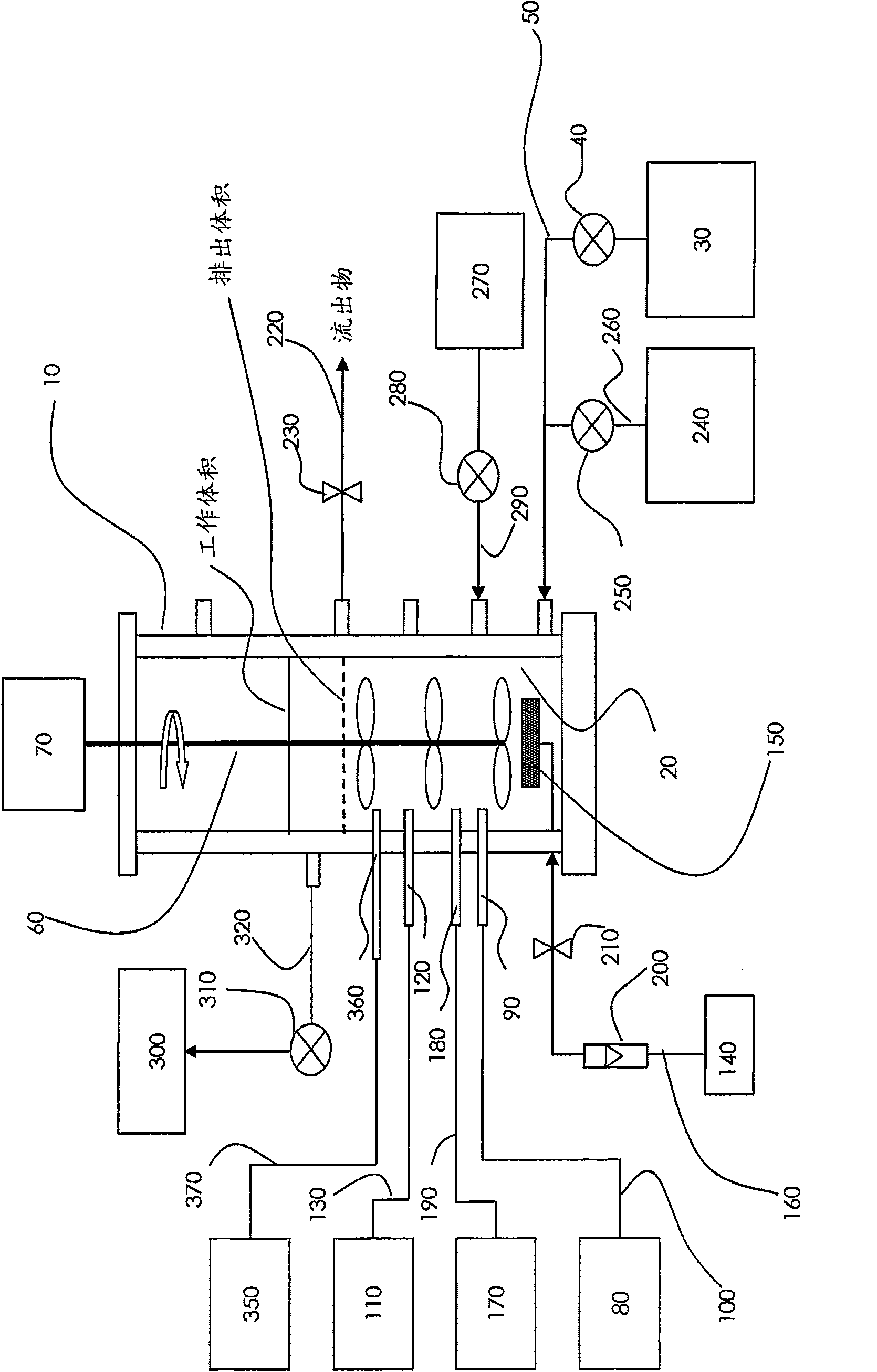

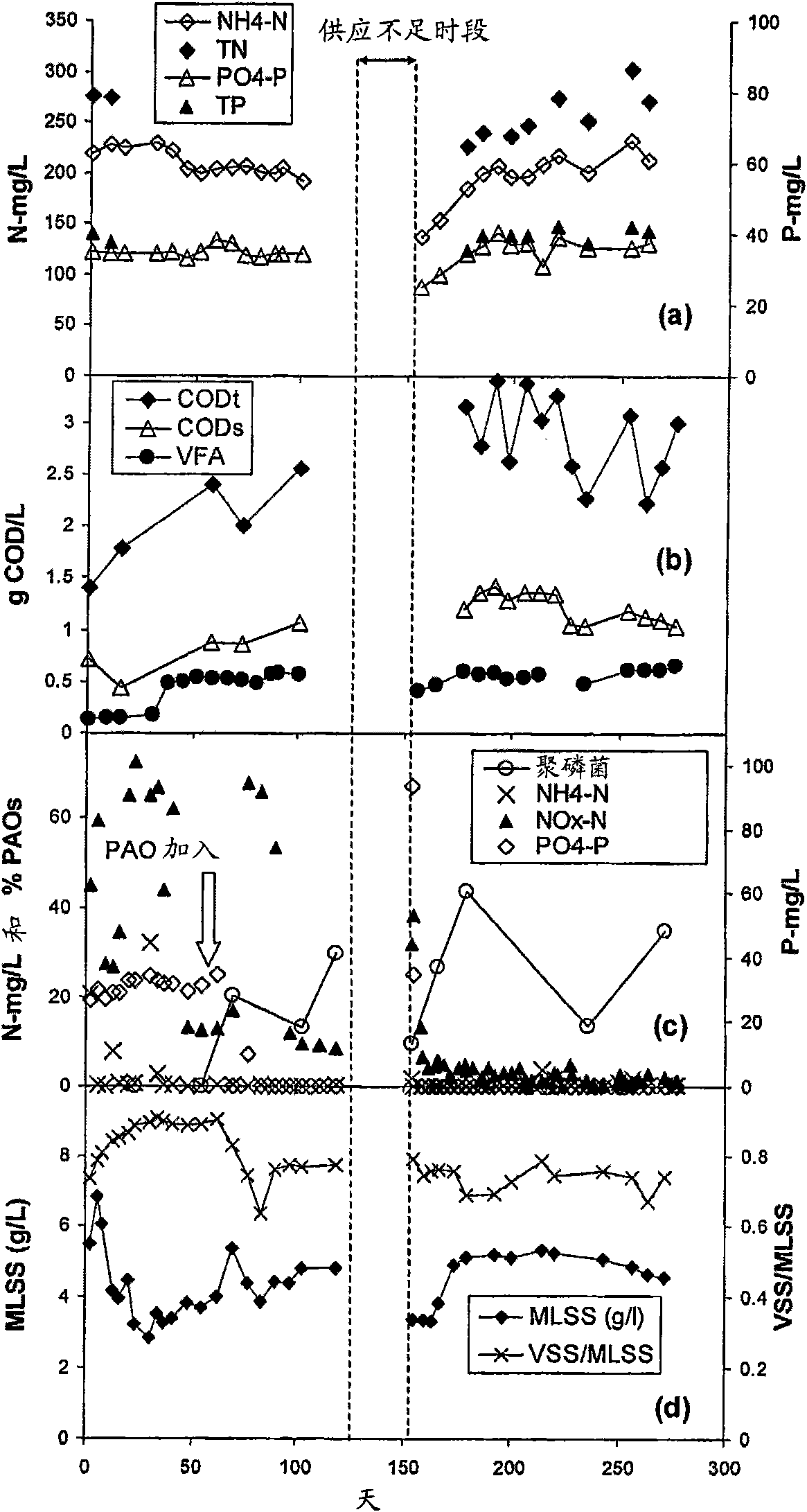

[0165] Establishment and operation of the reactor

[0166] In these studies, a laboratory-scale SBR with a working volume of 7L (according to figure 1 And above to build. See also Figure 15 ). The SBR was inoculated with non-EBPR (enhanced biological phosphorus removal) sludge from a real-scale SBR from Queensland, Australia that treats slaughterhouse wastewater. Since there seems to be no EBPR organisms in the initial inoculation sludge used, 1L of EBPR sludge enriched in the laboratory reactor (MLSS about 4g / L) was added on the 60th day to initiate the EBPR process in the reactor . The SBR was run in a temperature-controlled room (18-22°C) with a cycle time of 6 h. In each cycle, 1L of slaughterhouse wastewater (details are shown below) was pumped into the reactor during three filling periods, and the volume distribution was 0.5L, 0.3L and 0.2L, respectively. After each filling period is no ae...

Embodiment 2

[0217] Example 2-Slaughterhouse wastewater treatment for land irrigation

[0218] This plan is used to develop the operating strategy of SBR to produce effluent quality suitable for land irrigation. The same multi-feed principle used to produce effluent suitable for river discharge is used. However, the order of execution is different.

[0219] Land irrigation requires a high level of biological oxygen demand (BOD) removal (>95%), and a moderate level of nitrogen and phosphorus removal. It is believed that the presence of total phosphorus at a level of 10-20 mgP / L and total nitrogen at a level of 50-100 mgN / L in the treated effluent may be suitable for this purpose. Relative to nitrate, ammonia / ammonium is the preferred form of nitrogen in the final process effluent for land applications.

[0220]The SBR was inoculated with sludge from a local slaughterhouse in Queensland in June 2005 and constructed similarly to that described in Example 1. It started from June 2005 to August 200...

Embodiment 3

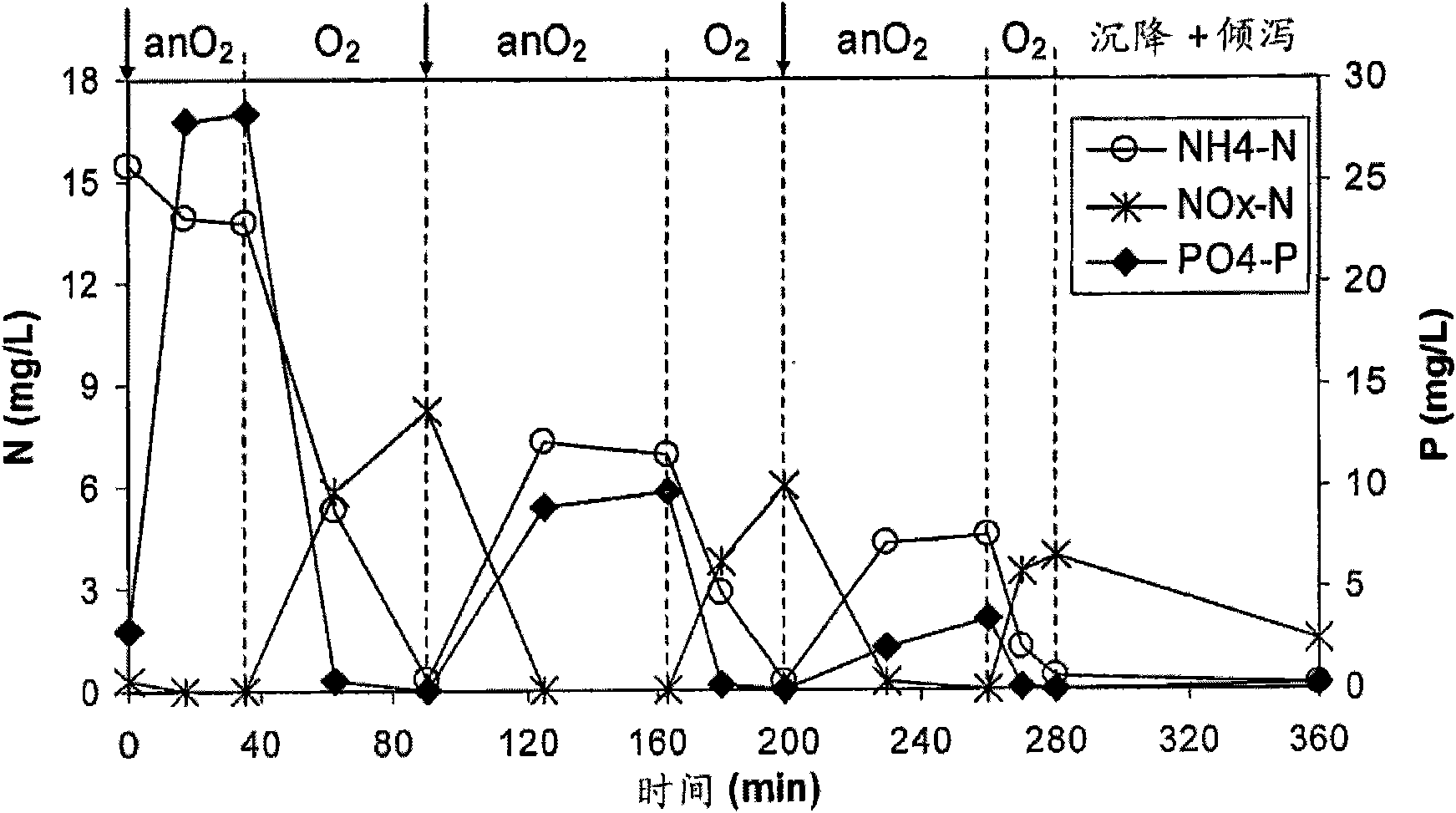

[0234] Example 3-Establish and maintain nitrosation / denitrification through automatic aeration control

[0235] This research focuses on aeration control to achieve nitrogen removal through nitrite instead of nitrate (see Figure 10A with 10B ). The control strategy is based on the slope of the pH signal and the oxygen uptake rate (OUR). During the aeration period, once the maximum pH value is reached and begins to decrease, the pH slope is calculated.

[0236] When the slope of the pH signal is lower than the minimum value input by the operator, the first condition for automatically stopping aeration is met.

[0237] The second condition is OUR. Since the purpose of the on-off aeration control system is to control DO in the reactor, OUR is directly related to O 2 The time the valve is "closed" is proportional to the filling time. When the valve is closed for longer than the maximum time entered by the operator, the second condition is met.

[0238] The third "safe" condition appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com