Device for detecting welding track of corrugated plate of container based on laser ranging

A technology of laser ranging and detection device, which is applied to measurement devices, optical devices, welding equipment, etc., can solve the problems of difficult application methods, detection accuracy, droplet transition form, and splash effects, etc., to facilitate streamlined operations. , Improve welding quality and welding efficiency, improve the effect of weld uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

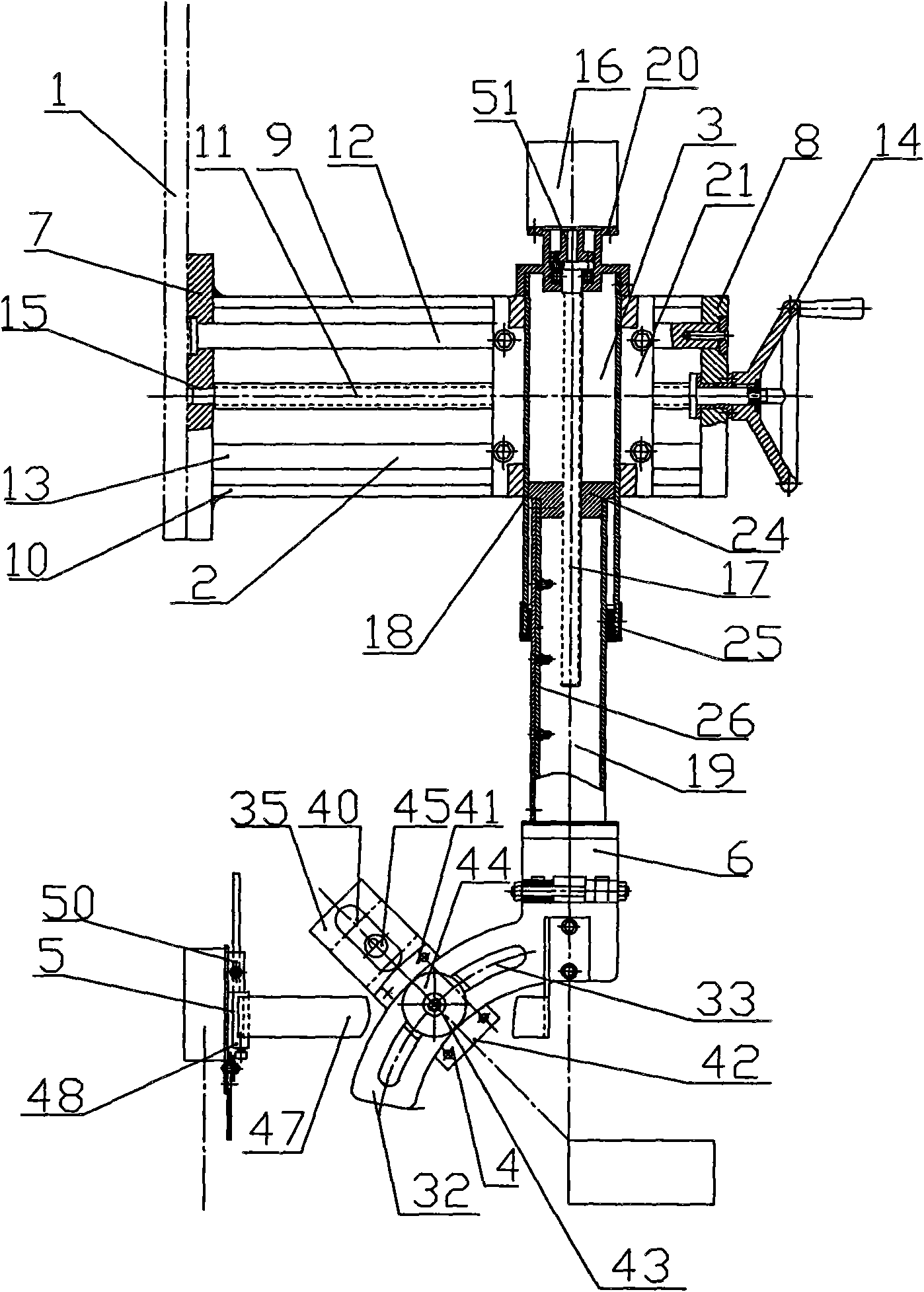

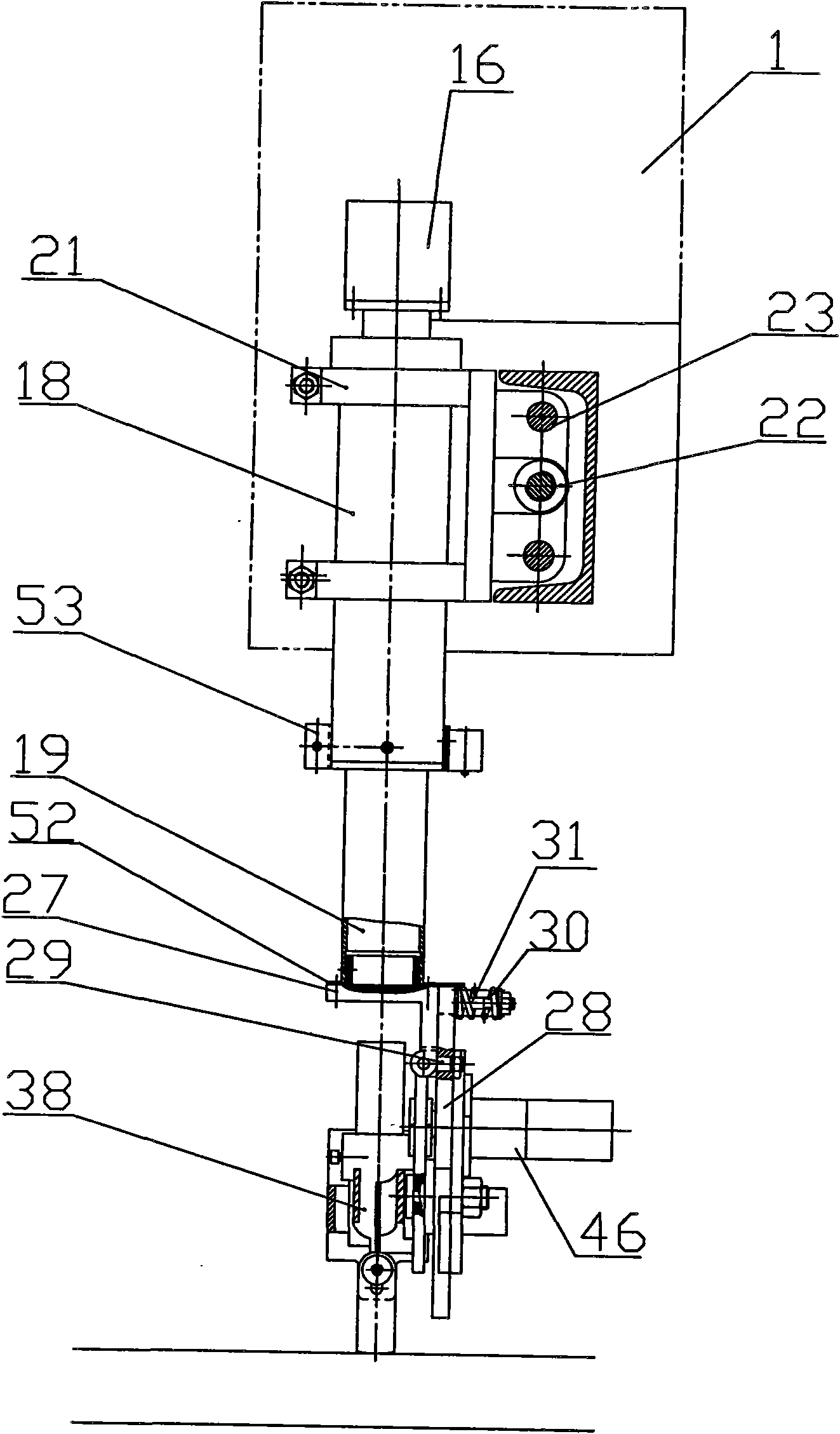

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Figure 1-6 Among them, the laser displacement sensor 54 and the welding torch position and posture adjustment device are connected to the circuit control device through a line, and one end of the welding torch spatial position and posture adjustment mechanism is fixed on the frame, and the laser displacement sensor 54 is arranged at the welding torch spatial position and posture adjustment mechanism. lower end. The lifting transmission part of the welding torch in the mechanism is driven by a servo motor, which drives the welding torch to adjust up and down. At the same time, the mechanism allows the adjustment of the inclination angle of the welding torch to meet the requirements of different welding processes. It can also realize the zigzag welding wire swing. The swing device is driven by a stepping motor and controlled by the main controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com