Gypsum particle dispersing agent and preparation method thereof

A dispersant and granule technology, applied in the field of gypsum particle dispersant and its preparation, can solve the problems of cumbersome operation and achieve the effect of low energy consumption, high efficiency and long-lasting structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

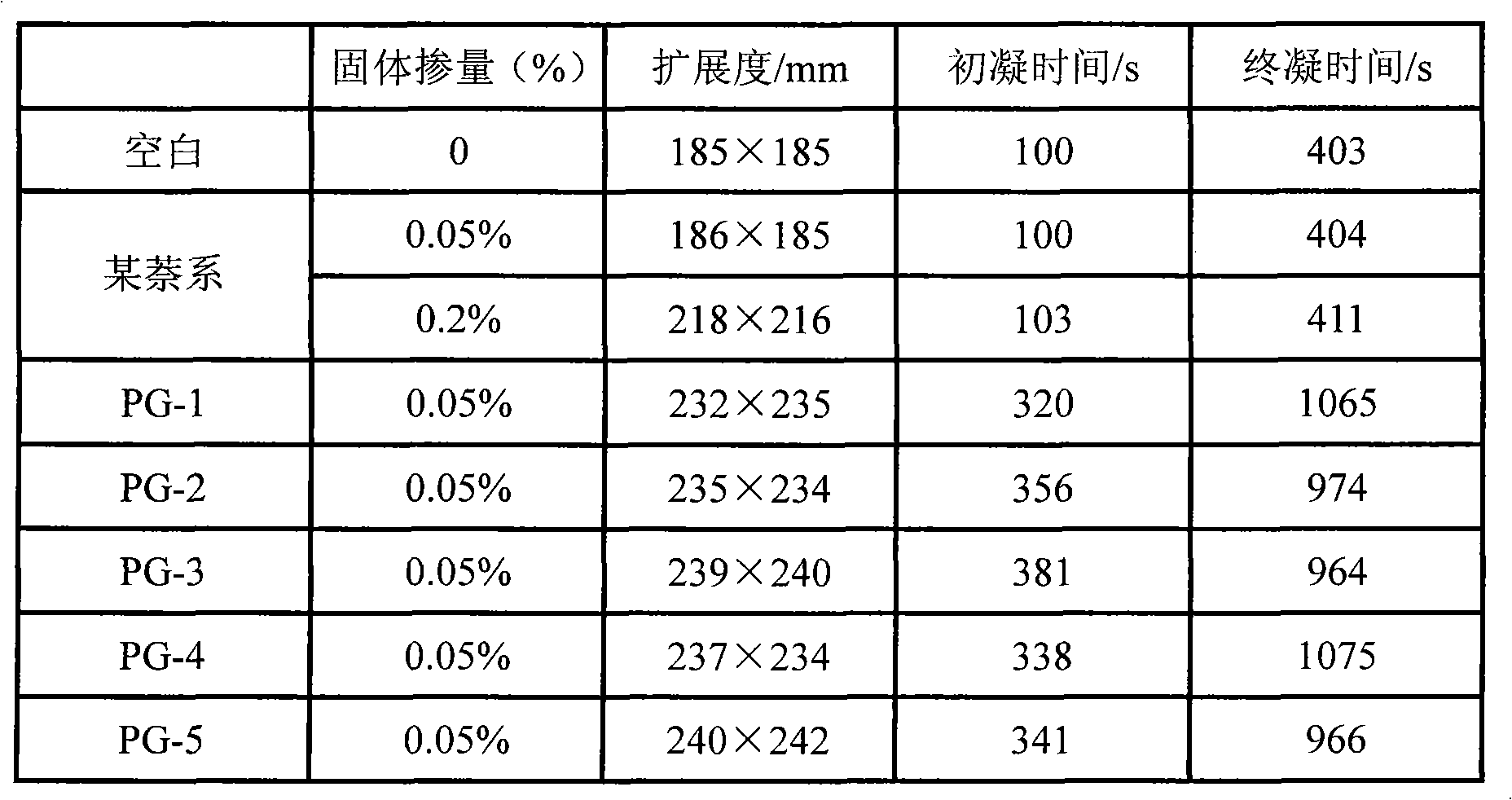

Embodiment 1

[0031] Add 120g of GE-1 and 120g of deionized water into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 80°C. Add dropwise the monomer aqueous solution that is mixed with 19.4g maleic anhydride, 3.6g p-styrene sulfonate, 1.3g 2-mercaptopropionic acid, 90g deionized water and 10g of potassium persulfate aqueous solution 10wt%, dropwise time control In about 90 minutes, the reaction temperature was controlled at 78-85°C. After the dropwise addition, the temperature was kept for 45 minutes to complete the polymerization. Add 28.6g of 28wt% ammonia water to neutralize to about pH 6.5. The gypsum particle dispersant of the present invention is obtained, which is designated as PG-1.

Embodiment 2

[0033]Add 120g of GE-2 and 120g of deionized water into a 500ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 80°C. At the same time, 10 g of monomer aqueous solution and 10 wt % ammonium persulfate aqueous solution mixed with 25.6 g maleic anhydride, 1.2 g mercaptoethanol, 70 g deionized water and 10 g of ammonium persulfate aqueous solution were added dropwise, the dropping time was controlled at about 90 minutes, and the reaction temperature was controlled at 78-85 ℃. After the dropwise addition, the temperature was kept for 45 minutes to complete the polymerization. Add 30 g of 28 wt % ammonia water to neutralize to about pH 6.5. The polycarboxylate gypsum dispersant of the present invention is obtained, which is designated as PG-2.

Embodiment 3

[0035] Add 120g of GE-3 and 120g of deionized water into a 500ml four-neck flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 85°C. Simultaneously add dropwise the monomer aqueous solution that is mixed with 14.3g maleic anhydride, 0.8g mercaptoacetic acid, 70g deionized water and 10g of the potassium persulfate aqueous solution of 7.8g and 20wt%, and dropwise time is controlled at about 120 minutes, and reaction temperature Control at 83-88°C. After the dropwise addition was completed, the insulation was kept for 30 minutes to complete the polymerization. Add 19.5 g of 28 wt % ammonia water to neutralize to about pH 6.5. The gypsum particle dispersant of the present invention is obtained, which is designated as PG-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com