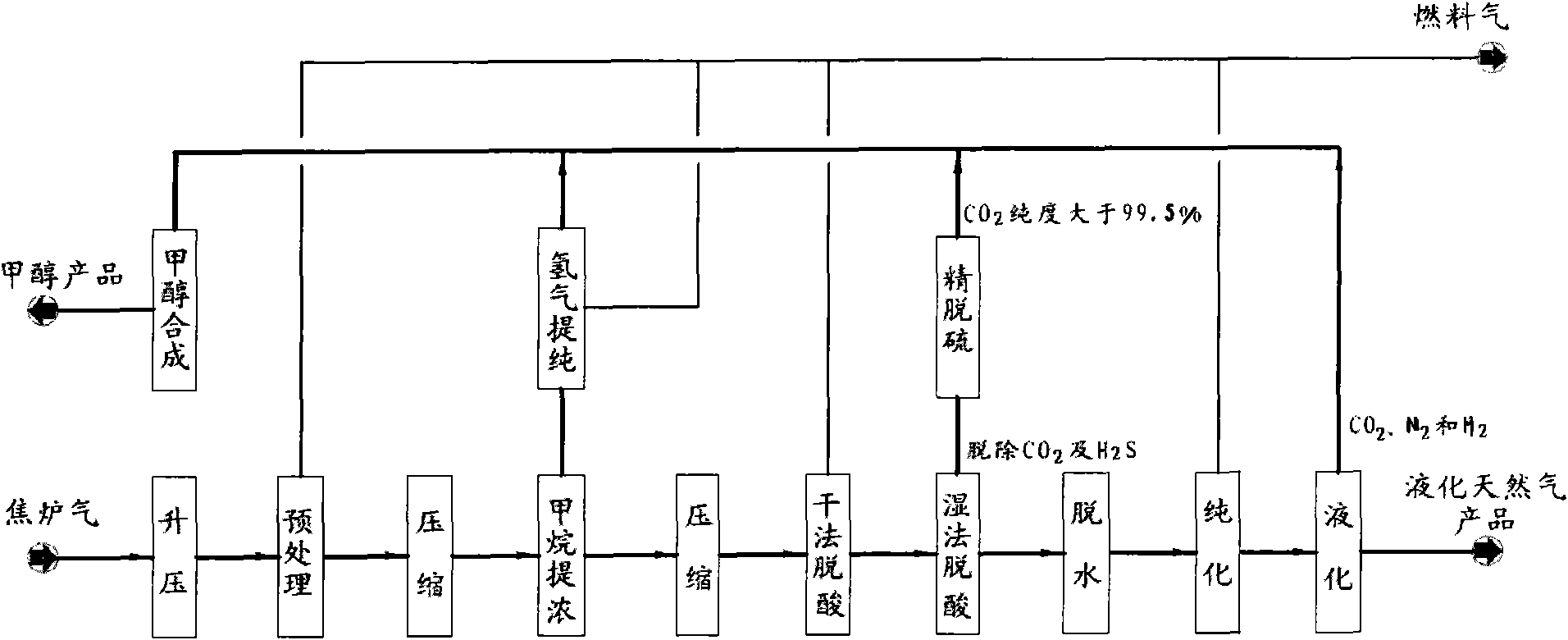

Method for producing liquefied natural gas and carbinol simultaneously

A technology for liquefied natural gas and methanol, applied in chemical instruments and methods, production of bulk chemicals, preparation of organic compounds, etc., can solve problems such as the risk of not being able to respond to market changes, and achieve the effect of reducing energy consumption and creating benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Coke oven gas at 20000Nm 3 The flow rate per hour is pressurized to 0.4MPa by the screw compressor and then enters the pretreatment process. The pretreatment adopts the temperature-swing-pressure-swing adsorption method. The adsorbent is coke plus activated carbon, and the benzene in the coke oven gas is removed at 35°C. , naphthalene, tar and HCN, using the tail gas from the hydrogen purification process as the regeneration medium; then the coke oven gas pressure is increased to 1.0MPa, and the temperature is controlled at 40°C before entering the pressure swing adsorption process (methane concentration). Here, 97% of H in the coke oven gas 2 through the adsorbent, while CH 4 , CO, CO 2 and N 2 is adsorbed. unadsorbed H 2 The flow rate is 13150Nm 3 / h, the concentration is 88.7%, the methane content is 1.03%, and then enters the pressure swing adsorption (hydrogen purification) process, at 0.9MPa, 40 ℃ its concentration is increased to 99.8%, sent out as the raw ma...

Embodiment 2

[0040] Coke oven gas at 18000Nm 3 The flow rate of / h is boosted to 0.08MPa by the Roots blower and then enters the pretreatment process. The temperature-swing-pressure-swing adsorption method is used for pretreatment. The adsorbent is coke plus molecular sieves. The benzene, naphthalene, tar and HCN in the coke oven gas are removed at 40°C, and steam is used as the regeneration medium; then the pressure of the coke oven gas is increased. After reaching 1.2MPa and cooling to 40°C, it enters the pressure swing adsorption process (methane concentration). 98% H in coke oven gas 2 through the adsorbent, while CH 4 , CO, CO 2 and N 2 is adsorbed. unadsorbed H 2 The flow rate is 11890Nm 3 / h, the concentration is 89%, the methane content is 1.05%, and then enters the pressure swing adsorption (hydrogen purification) process, at 1.1MPa, 40 ℃, the purity is increased to 99.9%, and sent to the methanol synthesis process as raw material gas. The adsorbed methane-rich gas (60.02%...

Embodiment 3

[0044] The flow rate is 25000Nm 3 / h of coke oven gas is pressurized to 0.05MPa by a centrifugal blower and then enters the pretreatment process. The pretreatment adopts the temperature-swing-pressure-swing adsorption method. Benzene, naphthalene, tar and HCN, using the tail gas from the hydrogen purification process as the regeneration medium; then the pressure of the coke oven gas is increased to 2.0MPa, cooled to 40°C, and then enters the pressure swing adsorption process (methane concentration). Here, 98.5% H in the coke oven gas 2 Through the adsorbent, CH 4 , CO, CO 2 and N 2 is adsorbed. The unadsorbed H2 flow rate is 16620Nm 3 / h, the concentration is 88.9%, the methane content is 1.01%, and then enters the pressure swing adsorption (hydrogen purification) process, at 0.9MPa, 40 ℃ its concentration is increased to 99.8%, sent out as the raw material gas of synthesizing methanol. The adsorbed methane-rich gas (60.15% methane content) is desorbed with a pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com