Method for producing isomaltulose without purification step

A technology for isomaltulose and its production method, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., and can solve problems affecting the quality of isomaltulose products and increasing production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

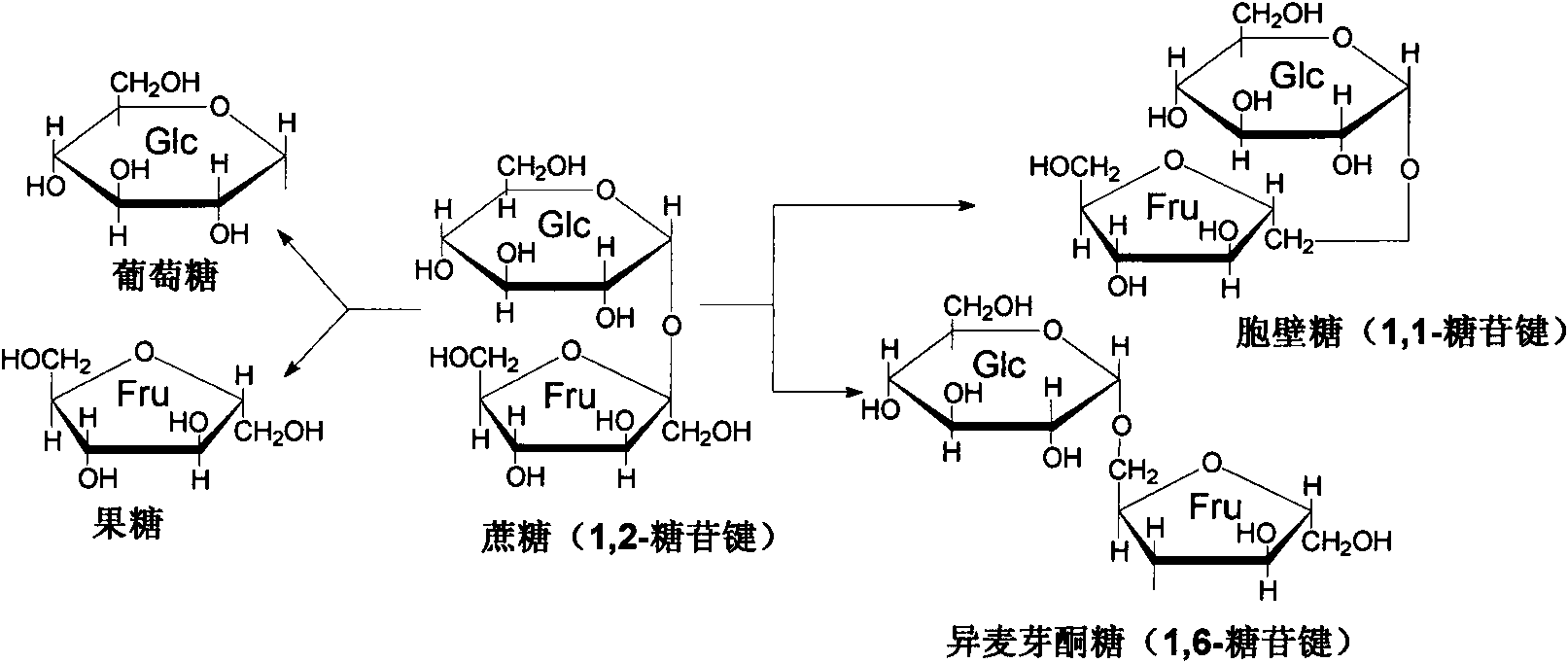

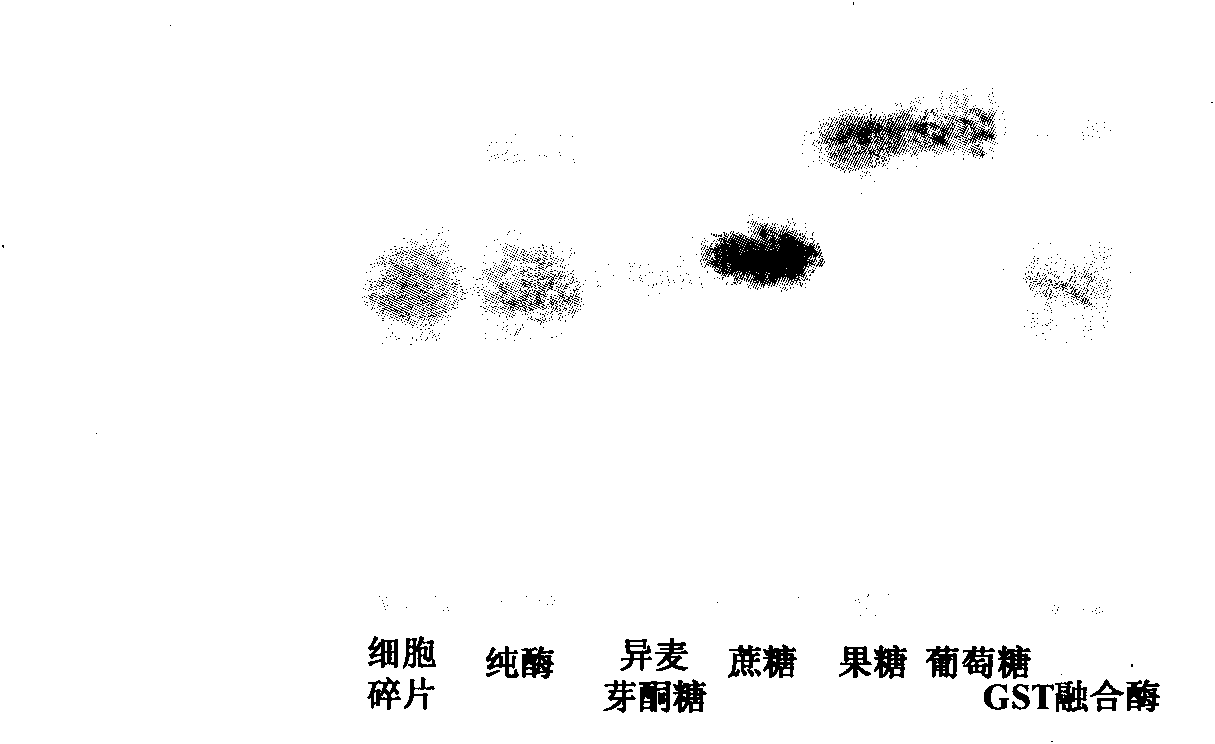

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, conversion tank batch conversion production isomaltulose

[0029] Klebsiella LSI was inoculated from the reserved slant into sucrose medium (2% sucrose, 0.1% yeast powder, 0.1% peptone, 0.05% magnesium sulfate, 0.1% NaH 2 PO 4 , 0.1% KNO 3 , pH6.6) in the Erlenmeyer flask of activation culture 8 hours (30 ℃, 150 rev / min), transfer in the fermentor that fresh sucrose medium is housed by 5% inoculum amount, ventilate and cultivate after 12 hours, in fermentor Cells were sonicated under aseptic conditions to prepare a suspension of active cell fragments. In a 10-ton conversion tank, 5%, 10%, 15% and 20% sucrose solutions were respectively prepared, sterilized at 95°C for 20 minutes, and then cooled to 30°C. Transfer the above active cell debris suspension into a 10-ton transformation tank at a ratio of 1:10, keep it warm at 30°C, and pass sterile air to maintain the positive pressure state in the transformation tank. When the sucrose concentration is 5% a...

Embodiment 2

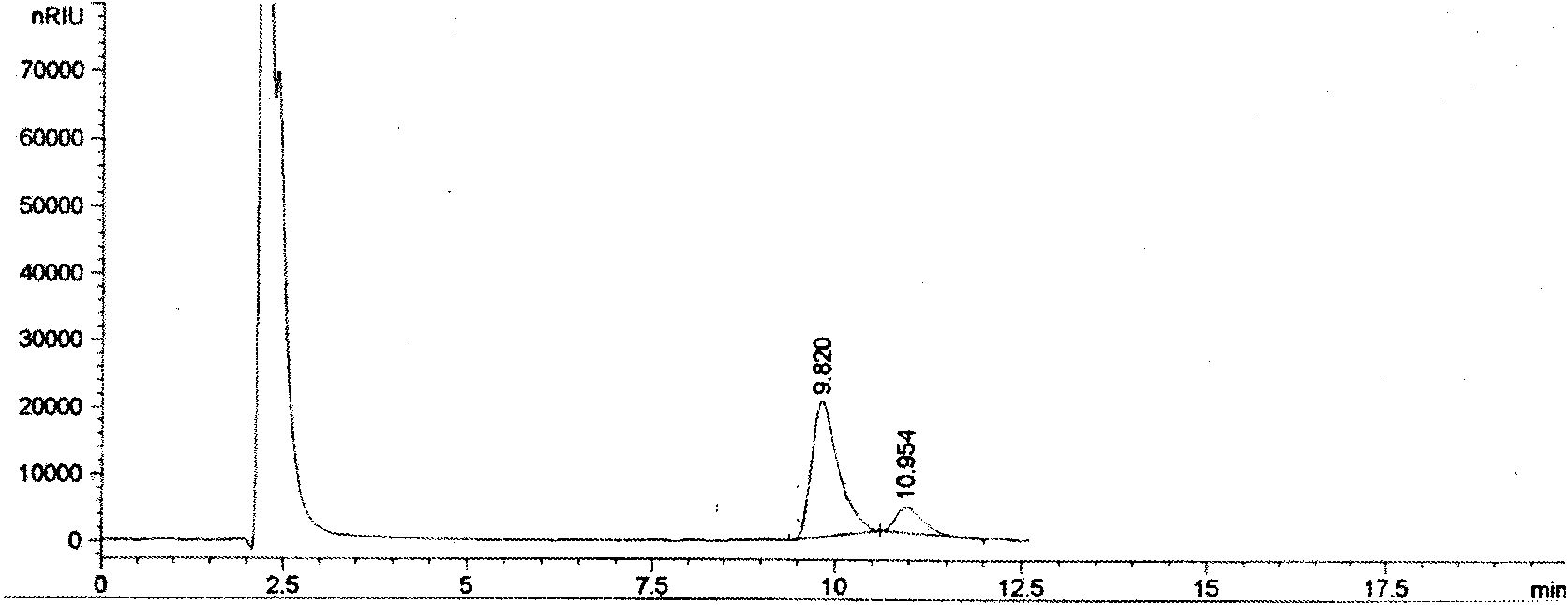

[0030] Embodiment 2, immobilized cell production isomaltulose

[0031] After every 5 ml of Klebsiella LSI bacterial culture solution was fully mixed with 100 ml of 2% sodium alginate solution, it was added dropwise to 0.65% (w / v) CaCl with a syringe 2 solution, and placed in the solution at 4°C for 4 hours to strengthen the immobilized particles. The immobilized cells were then transferred to a solution containing 0.1% CaCl 2 Sucrose medium (2% sucrose, 0.1% yeast powder, 0.1% peptone, 0.05% magnesium sulfate, 0.1% NaH 2 PO 4 , 0.1% KNO 3 , pH 6.6), cultured overnight at 30°C with shaking (150 rpm) to activate the immobilized cells. The immobilized cells were loaded into a 500 ml packed reactor, and 20% sucrose solution was added at different flow rates under the condition of 30° C., and the concentration of isomaltulose in the effluent was detected. When the sucrose flow rate was 4 ml / min, the sucrose conversion rate was 99.9%, and the concentrations of isomaltulose, mur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com