Erbium-doped lithium niobate crystal and preparation method thereof

A lithium niobate and crystal technology, which is applied in the field of erbium-doped lithium niobate crystals, can solve the problems of low laser gain, hindering the practical use of light sources, and not using optical fiber communication systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

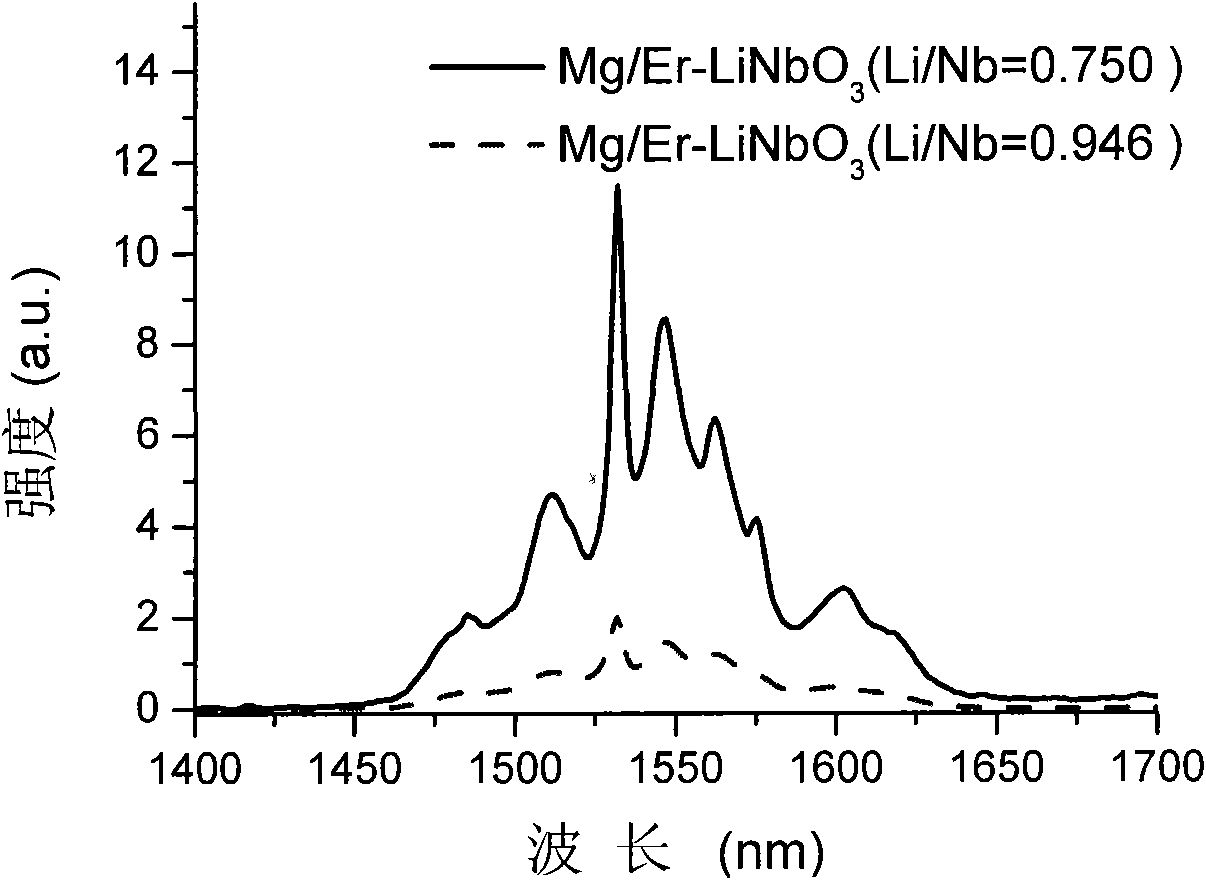

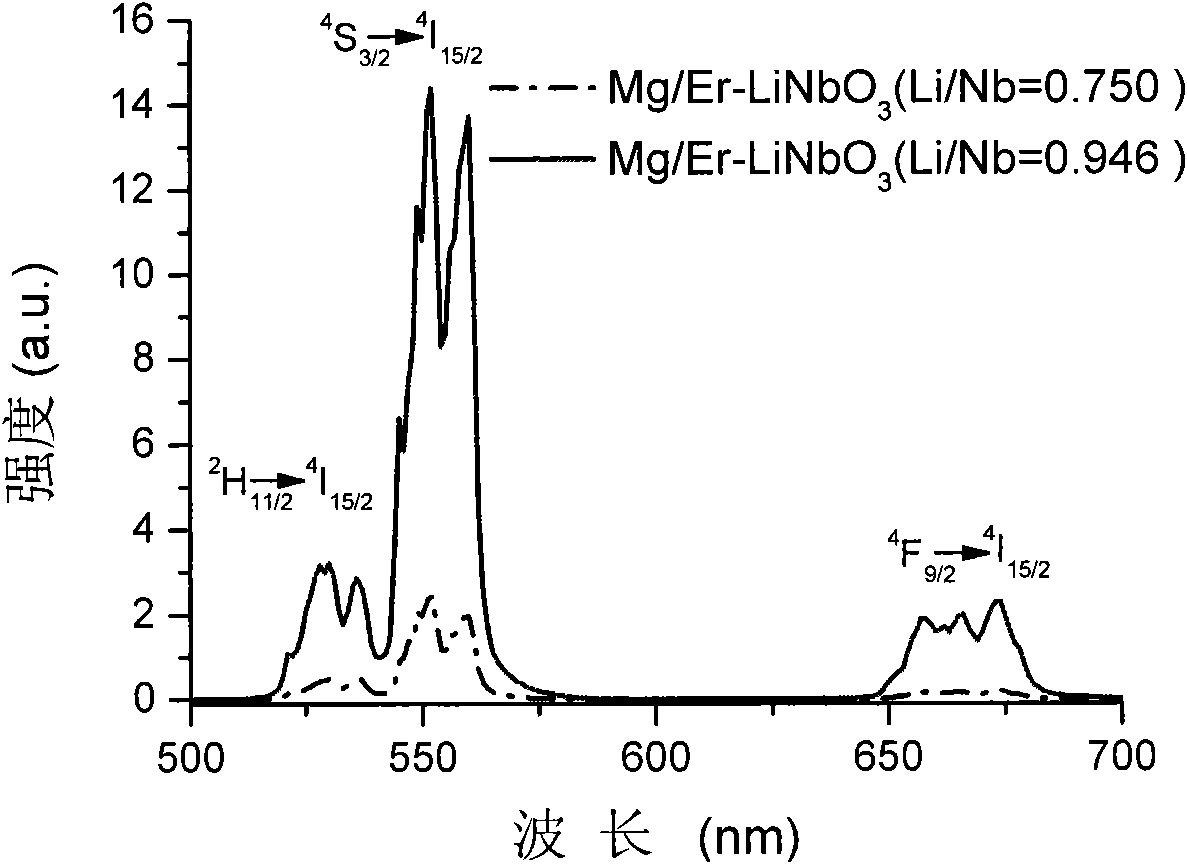

Embodiment 1

[0012] The specific steps of this embodiment include: 1) with 99.99wt% MgO, 99.99wt% Er 2 o 3 , 99.99wt% Nb 2 o 5 , 99.99wt% LiCO 3 As the basic raw material, the doping amount of MgO is 2mol%, Er 2 o 3 The doping amount is 1mol%, and the Li / Nb molar ratio=0.75, weighs each raw material respectively with this, and the total weight is 200g, fully mixes for standby; 2) Put the mixed raw material into the Pt crucible, adopt traditional The crystal growth is carried out by the pulling method, and the key parameters are: the pulling speed is 1mm / h, the axial temperature is 35°C / cm, and the rotation speed is 12rpm. The grown crystals are all light pink, with a diameter of 30mm and a height of 20mm. Growth stripes , High-quality crystals without cracks; 3) All crystals are heated at a temperature of 1200°C and a current density of 5mA / cm 2 Polarization under certain conditions; 4) Cut the crystal into the used wafer according to 10mm×10mm×3mm (Z×X×Y), and polish it with high pr...

Embodiment 2

[0014] The specific steps of this embodiment are the same as in Example 1, except that the specific steps include: 1) with 99.99wt% MgO, 99.99wt% Er 2 o 3 , 99.99wt% Nb 2 o 5 , 99.99wt% LiCO 3 As the basic raw material, the doping amount of MgO is 2.5mol%, Er 2 o 3 The doping amount is 2mol%, and the Li / Nb molar ratio=0.70, each raw material is weighed respectively with this, and total weight is 200g, fully mixes for standby; 2) Put the mixed raw material into the Pt crucible, adopt traditional The crystal growth is carried out by the pulling method, and the key parameters are: the pulling speed is 0.9mm / h, the axial temperature is 40°C / cm, and the rotation speed is 15rpm. The grown crystals are all light pink, and the diameter is 30mm, and the height is 20mm. High-quality crystals with growth streaks and no cracks.

Embodiment 3

[0016] The specific steps of this embodiment are the same as in Example 1, except that the specific steps include: 1) with 99.99wt% MgO, 99.99wt% Er 2 o 3 , 99.99wt% Nb 2 o 5 , 99.99wt% LiCO 3 As the basic raw material, the doping amount of MgO is 3mol%, Er 2 o 3 The doping amount is 3mol%, and the Li / Nb molar ratio=0.73, weighs each raw material respectively with this, and the total weight is 200g, fully mixes for standby; 2) Put the mixed raw material into the Pt crucible, adopt traditional The crystal growth is carried out by the pulling method, and the key parameters are: the pulling speed is 0.8mm / h, the axial temperature is 43°C / cm, and the rotation speed is 11rpm. The grown crystals are all light pink, and the diameter is 30mm, and the height is 20mm. High-quality crystals with growth streaks and no cracks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com