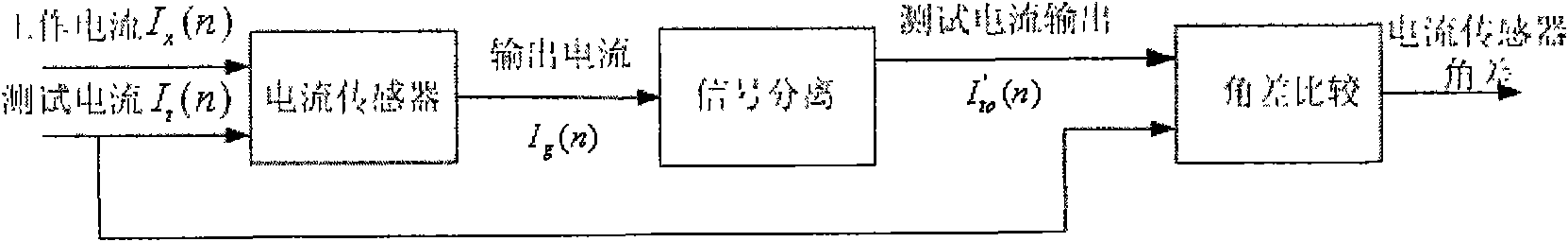

Method for monitoring current sensor angular difference online based on kernel independent component analysis

A current sensor, core-independent technology, applied to the phase angle between voltage and current, measuring electrical variables, instruments, etc., can solve problems such as complex calculations, inaccurate signal parameters such as frequency, amplitude and phase, and spectrum leakage , achieve good robustness, realize online calibration and verification, and achieve high separation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

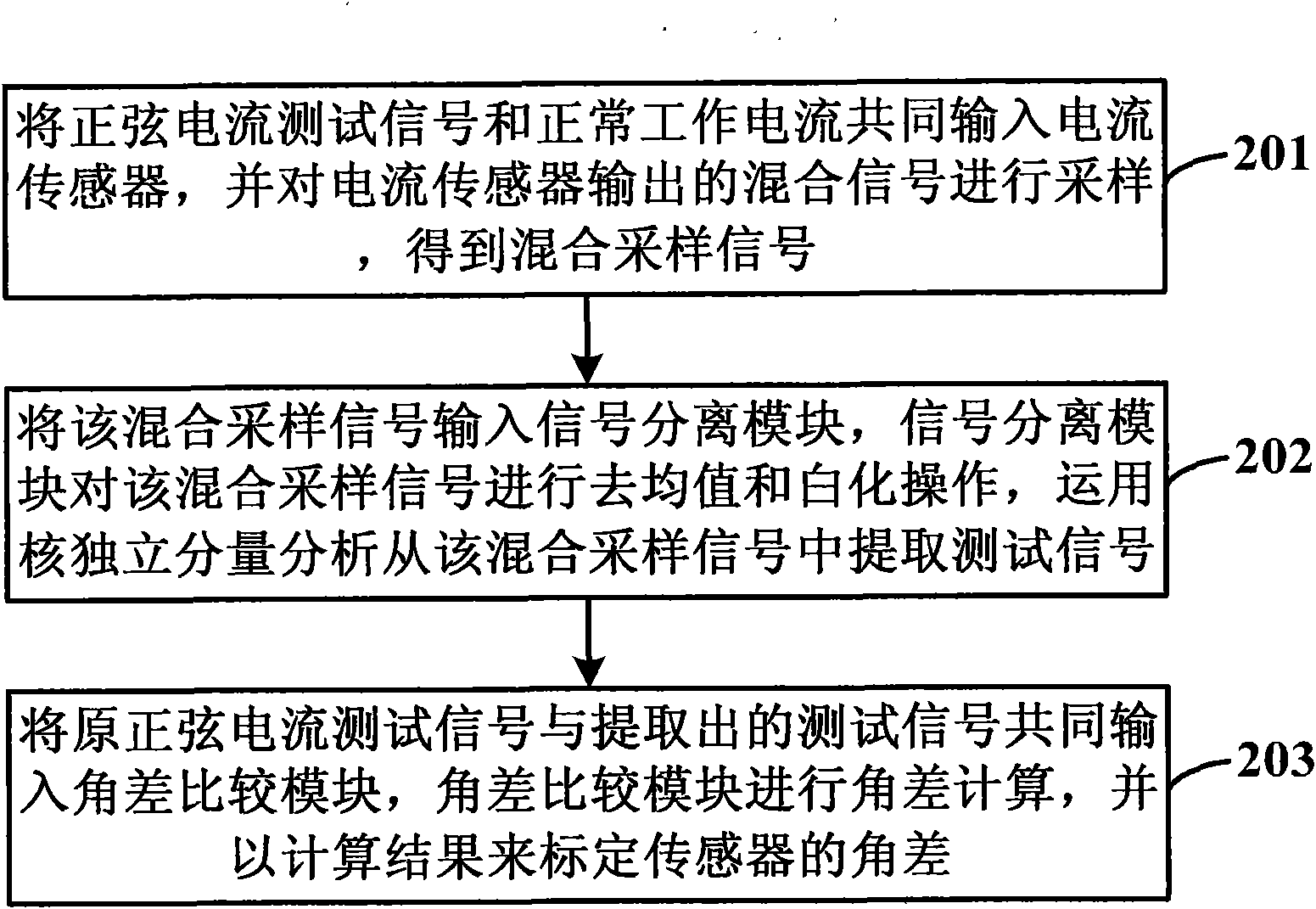

Method used

Image

Examples

Embodiment 1

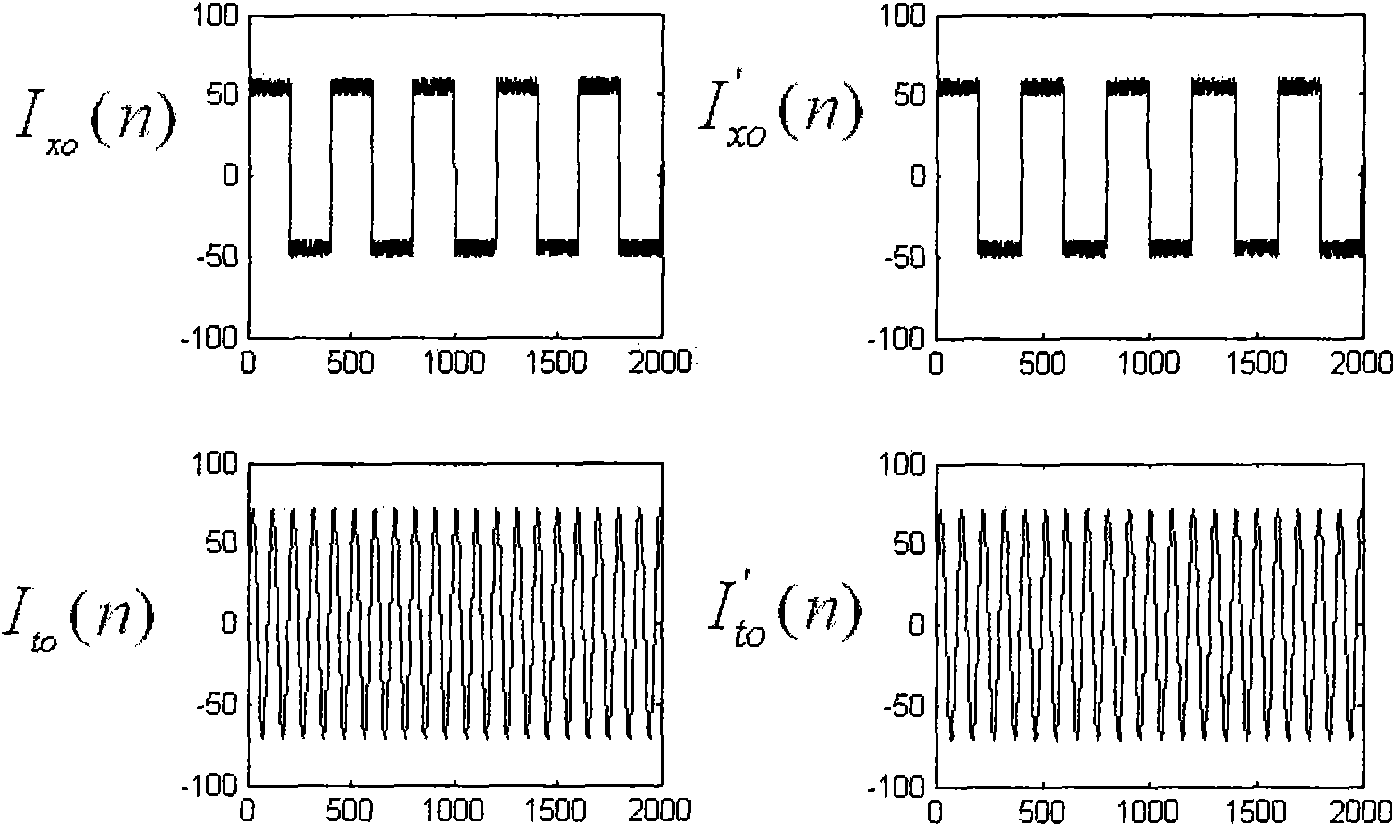

[0063] A square wave with a frequency of 50Hz and a signal-to-noise ratio of 18.73dB is used to simulate the output current I when the sensor is working normally when the test signal is not applied. xo (n), use a sine signal with a frequency of 203 Hz (in order to reduce the aliasing of the two signals in the frequency domain) and an initial phase of 0 as the output I of the test signal to (n), the two signals are superimposed according to the SNR 18.73dB to obtain the mixed signal I g (n). Both signals are sampled at a sampling interval of 50us, and finally a sampling point with a data volume of 10k is obtained.

[0064] Use this algorithm to I g (n) The result of a separation is as follows image 3 Shown. by image 3 From the separated waveforms of the two sets of signals in the middle, we can see that this algorithm can effectively separate the signal output by the sensor during normal operation and the single-frequency test signal.

Embodiment 2

[0066] Take three groups of current sensor working signal I x (n), the signal-to-noise ratio is 24.83dB, 18.73dB, 15.22dB, and each group of signals is separated 20 times by this algorithm. The maximum, minimum and average angle differences of the test signals before and after separation are calculated to verify the The performance of the algorithm under different system noise conditions. The results are shown in Table 1 below (unit: 0.0001rad):

[0067] Signal to noise ratio

[0068] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com