Rotary-type photocatalysed or adsorptive reactor

A wheel-type, photocatalytic technology, applied in the field of environmental protection, can solve the problems that affect the degradation of pollutants, COD reduction, catalyst, fluid and sunlight contact area are not large enough, etc., to improve the treatment effect, compact structure, and realize the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

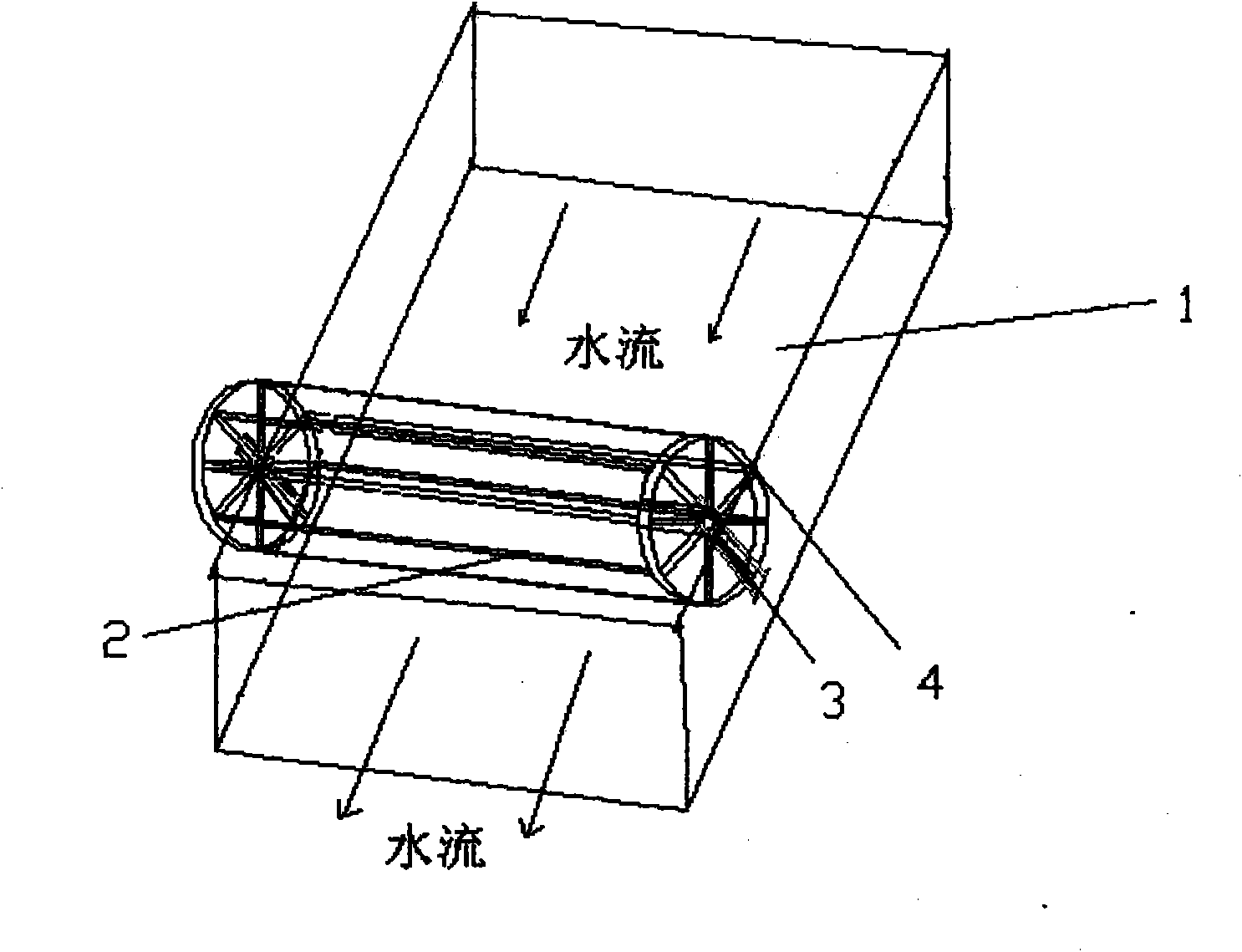

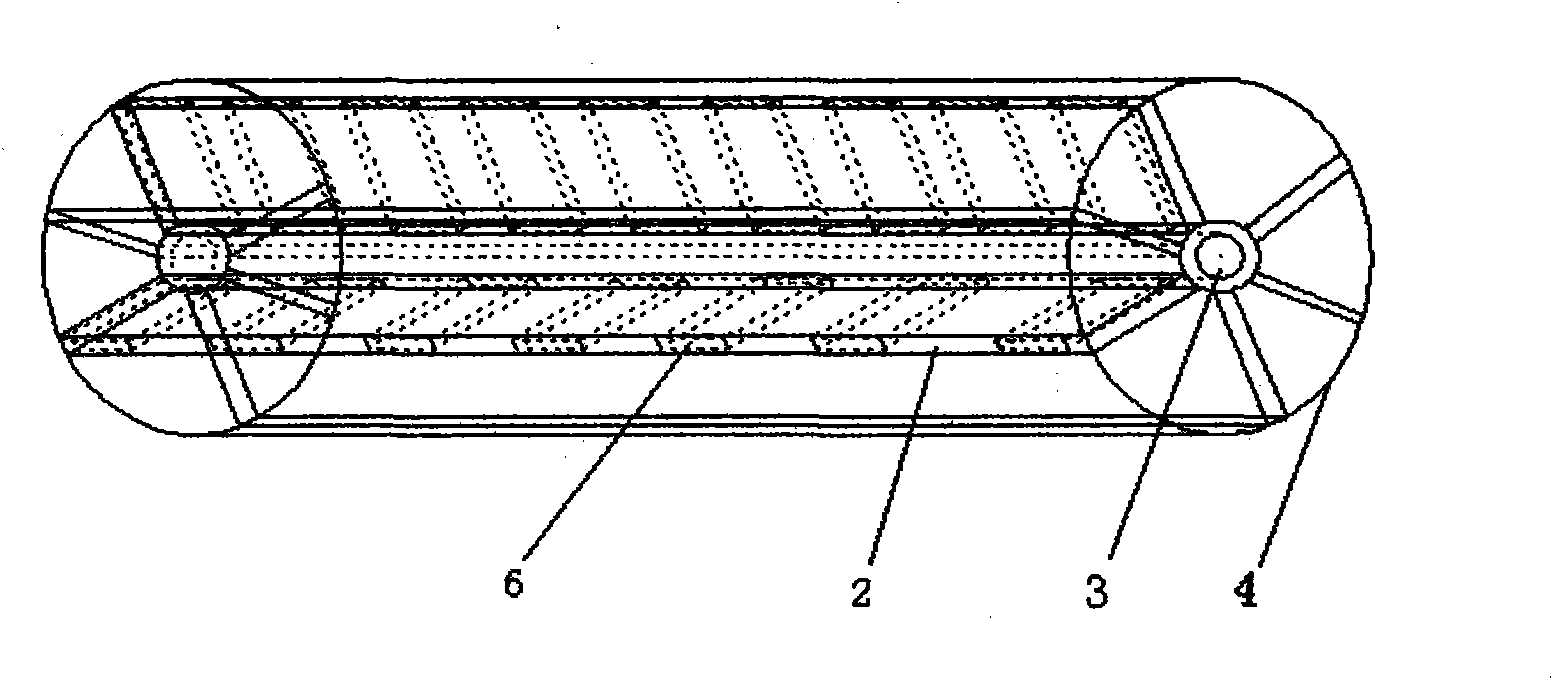

[0026] from figure 1 , figure 2 , image 3 , Figure 4 Visible, a kind of runner-type photocatalytic or adsorption reactor of the present invention mainly comprises tank 1, runner 4, water inlet and outlet, light source etc., is characterized in that: described tank 1 is placed obliquely, and runner 4 is horizontal Placed in the water tank 1, connected and fixed with the two sides of the water tank 1 through the central axis 3, the runner 4 is provided with a slot 2, and a thin plate 6 is inserted into the slot 2, and fixed by bolts. Both sides of the thin plate 6 are loaded with catalysts, films or adsorbents, 1 / 2 to 2 / 3 of the runner 4 is above the water surface, and the sunlight or ultraviolet lamp 9 is used as the light source; the water inlet is located on the top of the water tank 1, The water outlet is arranged at the bottom of the water tank, and the water flow impacts the thin plate 6, so that the runner 4 rotates slowly. If the water tank is installed indoors, i...

Embodiment 2

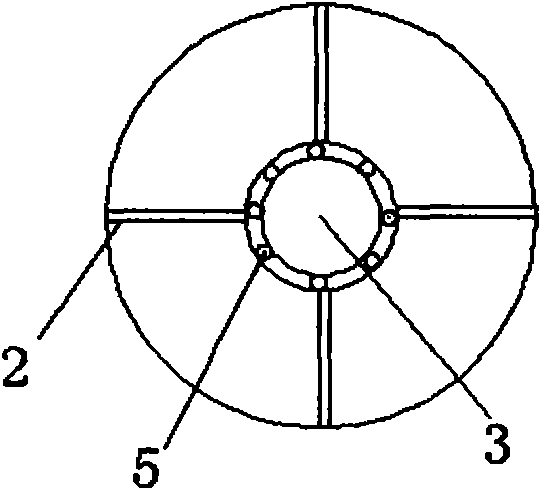

[0029] from Figure 4 , 5 , 6 Visible, a kind of runner type photocatalytic or adsorption reactor, mainly has water tank 1, runner 4, water inlet, water outlet, motor 7, light source 9, it is characterized in that: runner 4 is horizontally placed in water tank 1 , the central shaft 3 is connected to the bearings 5 at the openings on both sides of the water tank 1, and the speed-regulating motor 7 is driven by the meshing of the gear on the central shaft 3 through the synchronous toothed belt 8; the runner 4 is provided with a card slot 2. There is a thin plate 6 built into the card slot 2, and both sides of the thin plate 6 are loaded with a catalyst thin layer, film or adsorbent. 1 / 2 to 2 / 3 of the runner 4 is above the water surface, and the sunlight or A UV lamp was used as the light source. Likewise, the sink is placed indoors with a UV lamp as the light source.

[0030] In the aforementioned rotary photocatalytic or adsorption reactor, the thin plate 6 is an ordinary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com