Polyvinyl alcohol film and preparation method thereof

A polyvinyl alcohol film and polyvinyl alcohol resin technology, applied in the field of materials, can solve the problems of lack of research results with independent intellectual property rights, manufacturing costs, unsuitable product prices, weak research strength, etc., and achieve good gloss and transparency, Excellent mechanical properties, reduced equipment costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

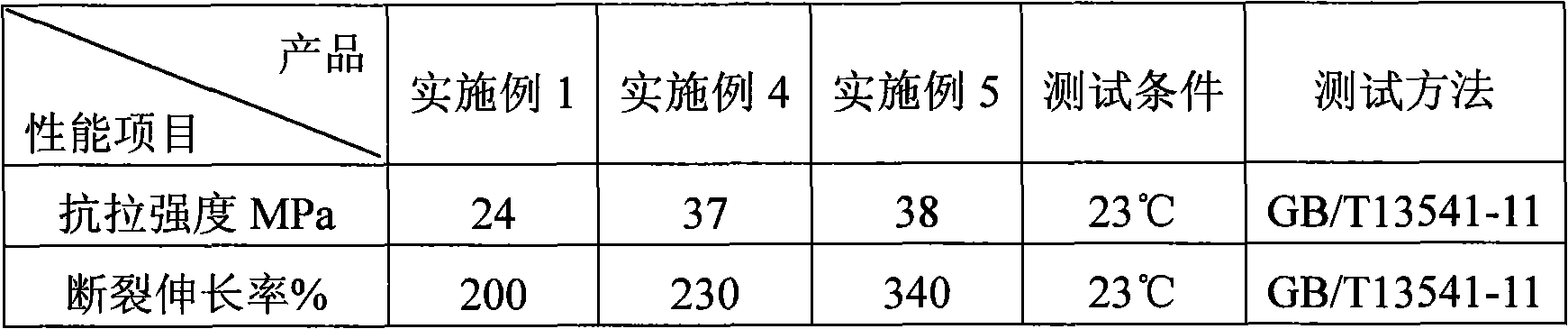

Examples

Embodiment 1

[0025] Add 180g of latent solvent DMF (Shanghai Reagent Factory), 60g of polyvinyl alcohol resin PVA17-88 (Sichuan Vinylon Factory), 4g of glycerin, 0.1g of n-butanol and 1g of borax into a 500mL three-necked flask, stirring at 800 rpm Then, gradually heat the temperature up, and use the back distillation method to dissolve the PVA resin at a high temperature of 130-140°C for 2 hours to make a completely dissolved high-concentration PVA solution. Stop stirring, maintain a temperature of about 130°C, and let the PVA solution stand to naturally remove bubbles in the solution for 1 to 1.5 hours. Then, at this temperature, the PVA solution with all bubbles removed is added to a Pingfeng casting mold preheated to a temperature of 100~110℃, and it is poured onto a mirror steel plate at a temperature of 10~20℃. It quickly becomes condensed after being quenched. Glue film. Then peel off the gel film from the steel plate, fix it with a metal frame, and put it in an oven at a temperature of...

Embodiment 2

[0027] The method is the same as in Example 1, except that the latent solvent is NMP (Shanghai Reagent Factory), the plasticizer is dioctyl phthalate, the defoamer is n-octanol, the gel enhancer is boric acid, and the dissolution temperature is It is 145~150℃.

Embodiment 3

[0029] The method is the same as in Example 1, except that the latent solvent is DMAC (Shanghai Reagent Factory), and the dissolution temperature is 135-145°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com