Convective waste heat boiler for generating superheated steam

A technology of superheated steam and waste heat boiler, which is applied in the field of convection waste heat boiler, and achieves the effects of good thermal expansion resistance, improved conversion efficiency, and fewer welding seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

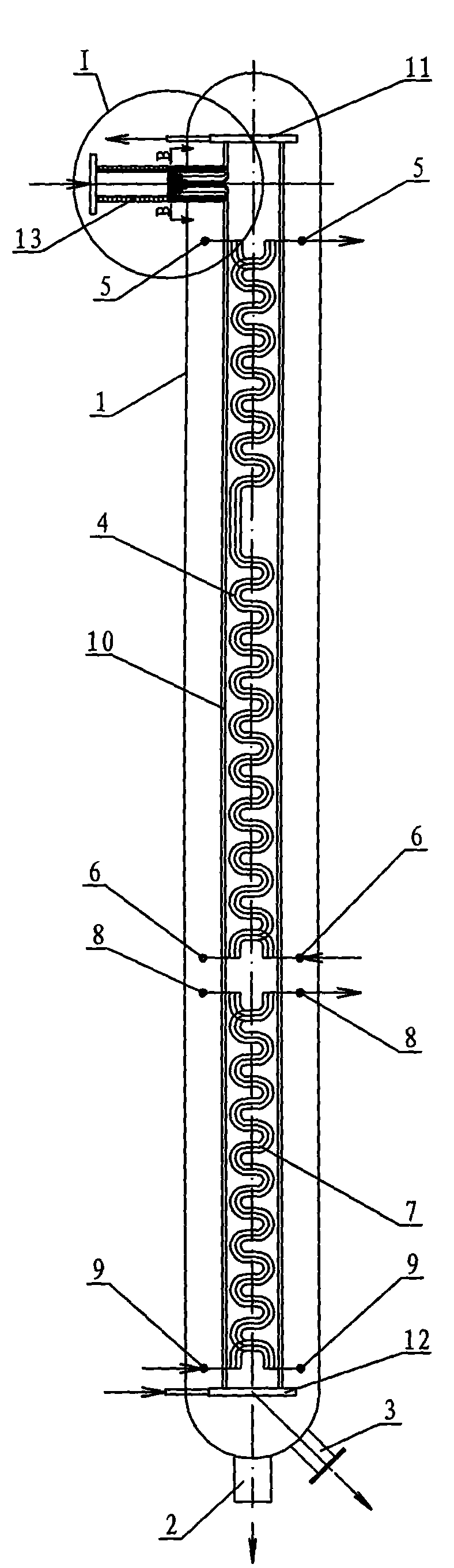

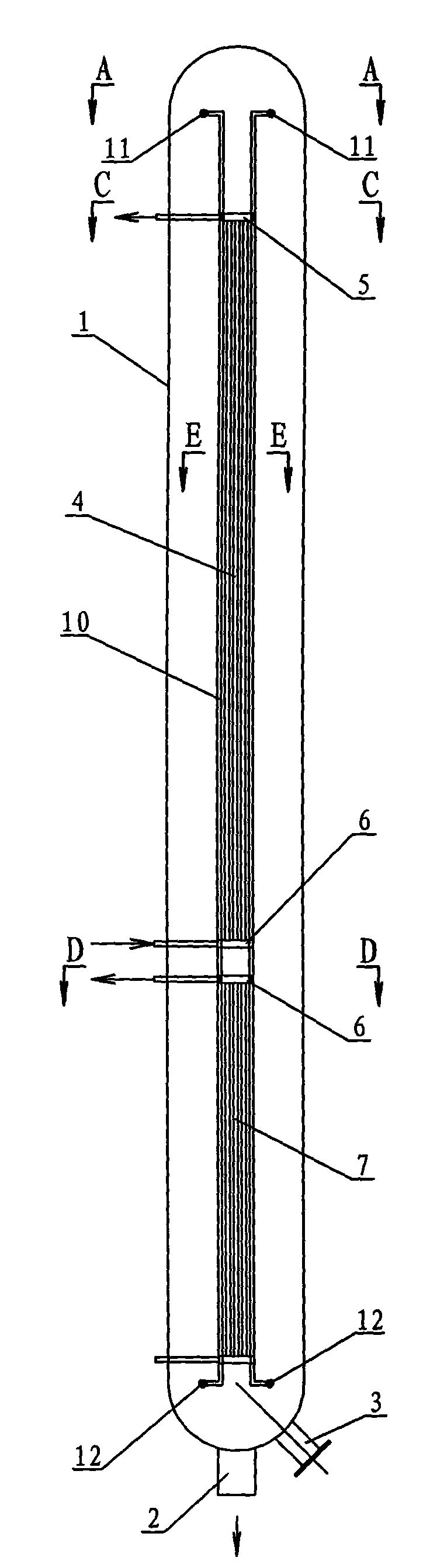

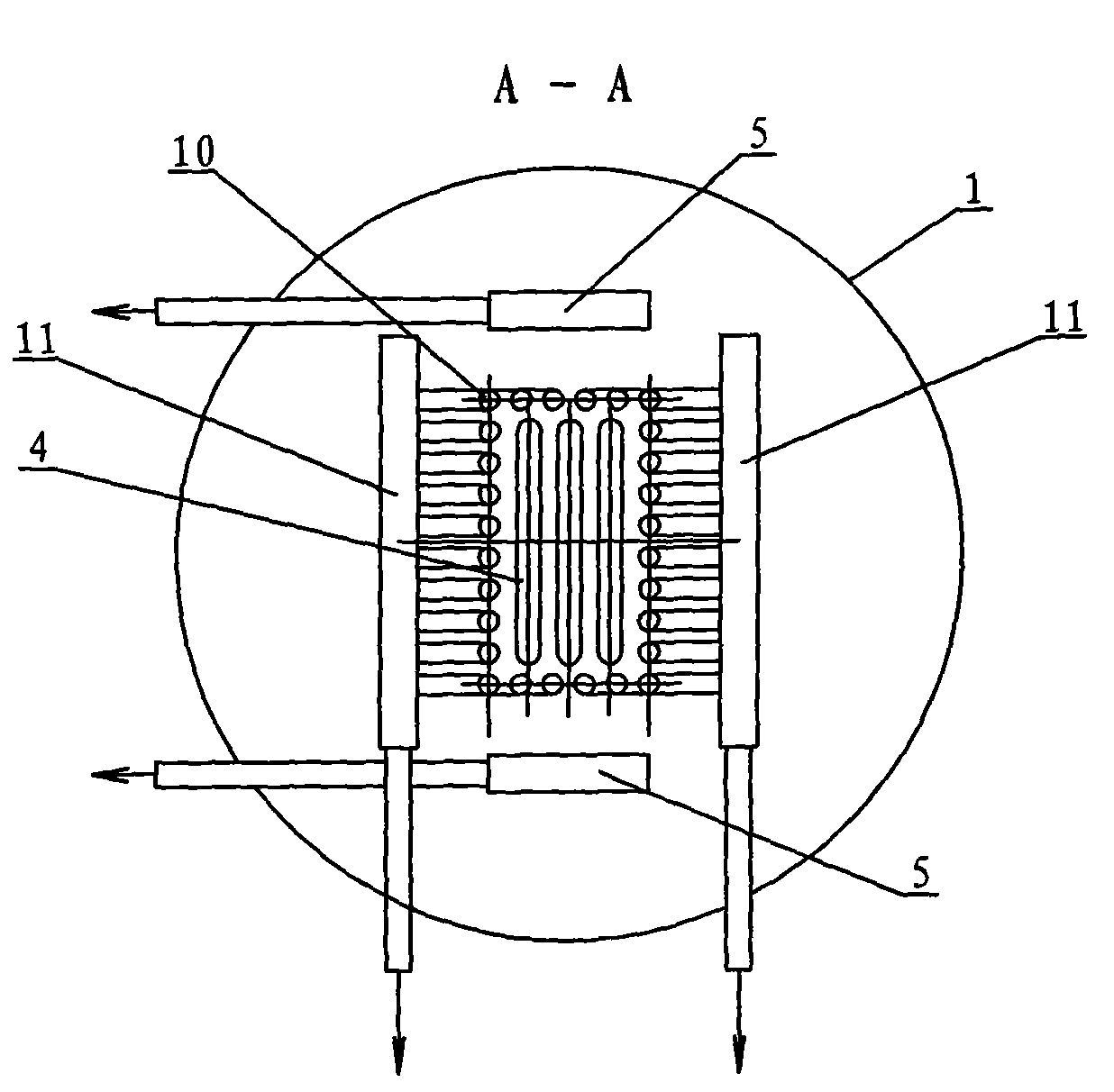

[0007] Specific implementation mode 1: Combination Figure 1~Figure 8 To explain this embodiment, this embodiment includes a boiler body 1, a pressure tube 2, at least two superheater coils 4, two superheater upper headers 5, two superheater lower headers 6, and at least one economizer Coiled tube bundle 7, two economizer upper header 8, two economizer lower header 9, tube assembly 10, two tube panel upper header 11, two tube panel lower header 12 and coarse The gas connecting pipe 13 and the pressure pipe 2 are arranged on the outer wall of the bottom of the boiler body 1 and communicate with the boiler body 1. The outer wall of the lower part of the boiler body 1 is provided with an inspection manhole 3, and the tube assembly 10 consists of several risers 10 -1. It is composed of several connecting plates 10-2 and several connecting pipes 10-3, several stand pipes 10-1 are arranged in parallel, and several stand pipes 10-1 are enclosed in a square tube shape, and two adjacent sta...

specific Embodiment approach 2

[0008] Embodiment 2: The working medium in the coiled tube bundle 4 of the superheater in this embodiment is superheated steam, the temperature of which is greater than the saturation temperature under the working pressure. Such a design can increase the superheating area of the serpentine tube bundle 4 of the superheater and increase the temperature of the superheated steam outlet, thereby improving the power generation capacity. The other methods are the same as the first embodiment.

specific Embodiment approach 3

[0009] Embodiment 3: The working medium in the riser 10-1 and the connecting pipe 10-3 in the tube assembly 10 of this embodiment is water or a mixture of water and steam. This is designed to absorb the sensible heat of the crude gas in the cylindrical cavity of the tube assembly 10. The other methods are the same as the first embodiment.

[0010] The working process of the present invention: the crude gas enters the square cylindrical cavity of the tube assembly 10 through the crude gas connecting pipe 13, and the temperature of the crude gas at the inlet of the crude gas connecting pipe 13 is about 500-700°C. The inner cavity of the cylindrical tube assembly 10 flows downward, and the superheater serpentine tube on the superheater serpentine tube bundle 4, the economizer serpentine tube on the economizer serpentine tube bundle 7 and the tube assembly 10 The water in the riser 10-1 is heated to reach or close to the saturation temperature. At the same time, the water vapor in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com