Method for measuring straightness accuracy and position thereof based on double frequency interference principle

A measuring device and straightness technology, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effect of eliminating the influence of environmental factors, simple optical path structure, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

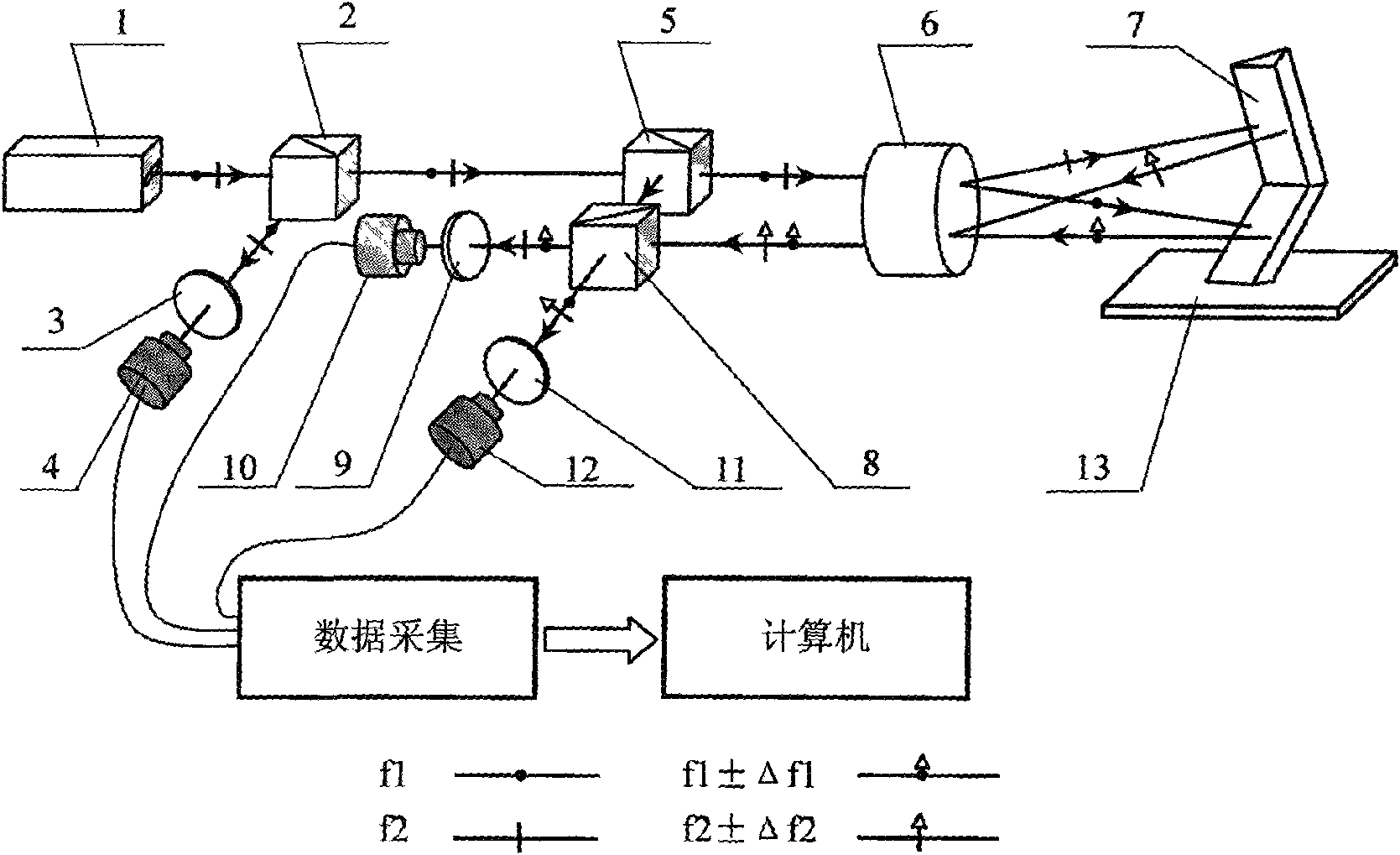

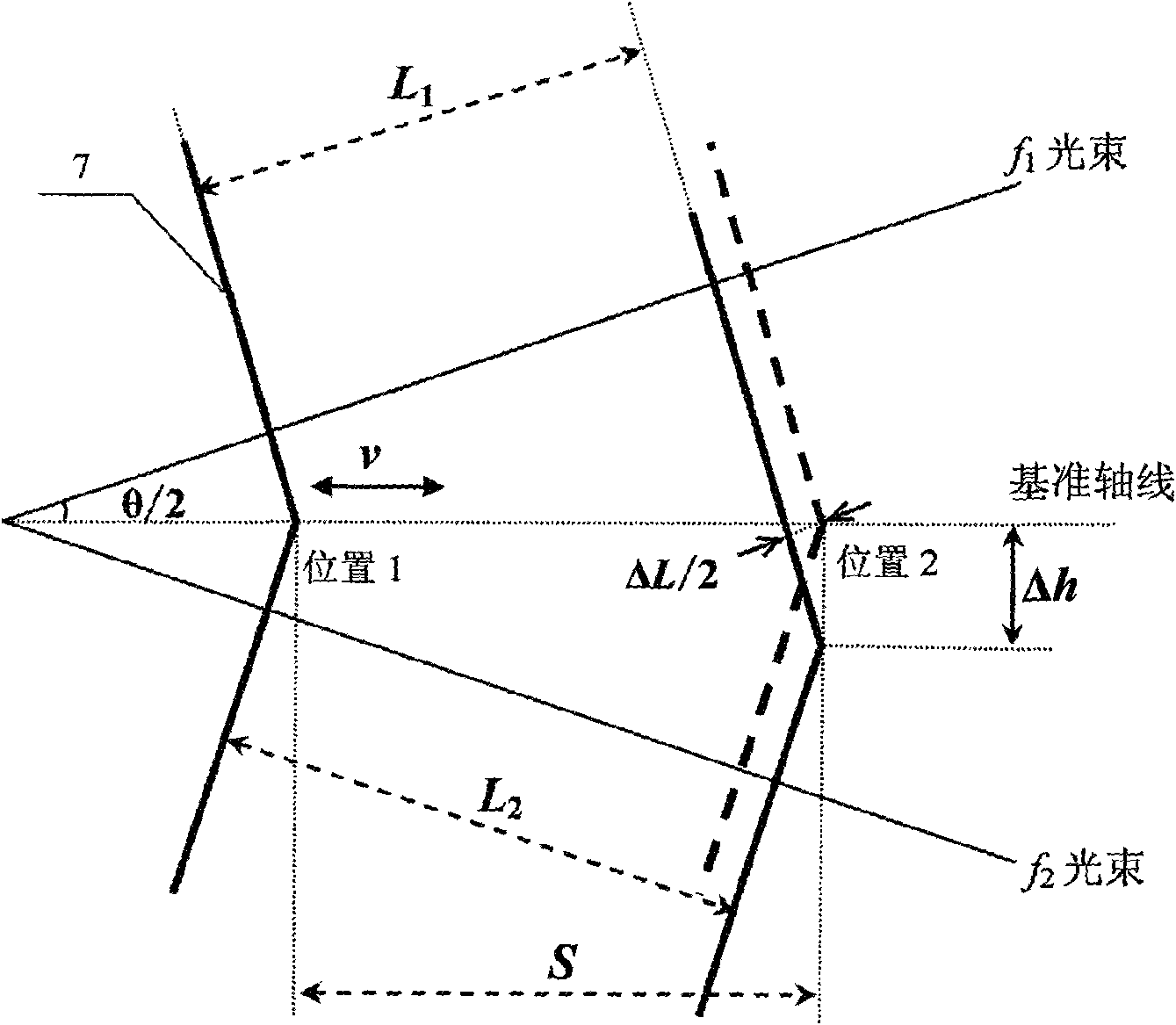

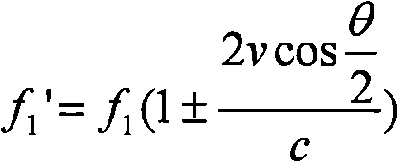

[0016] The measurement method of straightness and its position based on the principle of double-frequency interference is as follows: figure 1 Shown: The light source is a transverse Zeeman effect He-Ne dual-frequency laser 1, the laser has a central wavelength of 632.8nm and outputs two different frequencies f 1 and f 2 The orthogonal linearly polarized light has a frequency difference of 1.9MHz. The laser beam emitted by the laser 1 is divided into two beams by the ordinary beam splitter 2, and the reflected beam is incident on the first analyzer 3. Since the transmission direction of the analyzer is at an angle of 45° to the two orthogonal linearly polarized lights, the two beams can be separated Orthogonal linearly polarized light is decomposed into the same vibration transmission direction to form a beat frequency, which is received by the first photodetector 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com