Fabricating method of soft template with nanometer structure

A nanostructure and manufacturing method technology, applied in the field of nanomanufacturing, can solve the problems of high manufacturing cost, restricting the research of nanoimprinting technology, long cycle, etc., and achieve the effects of convenient operation, low manufacturing cost and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

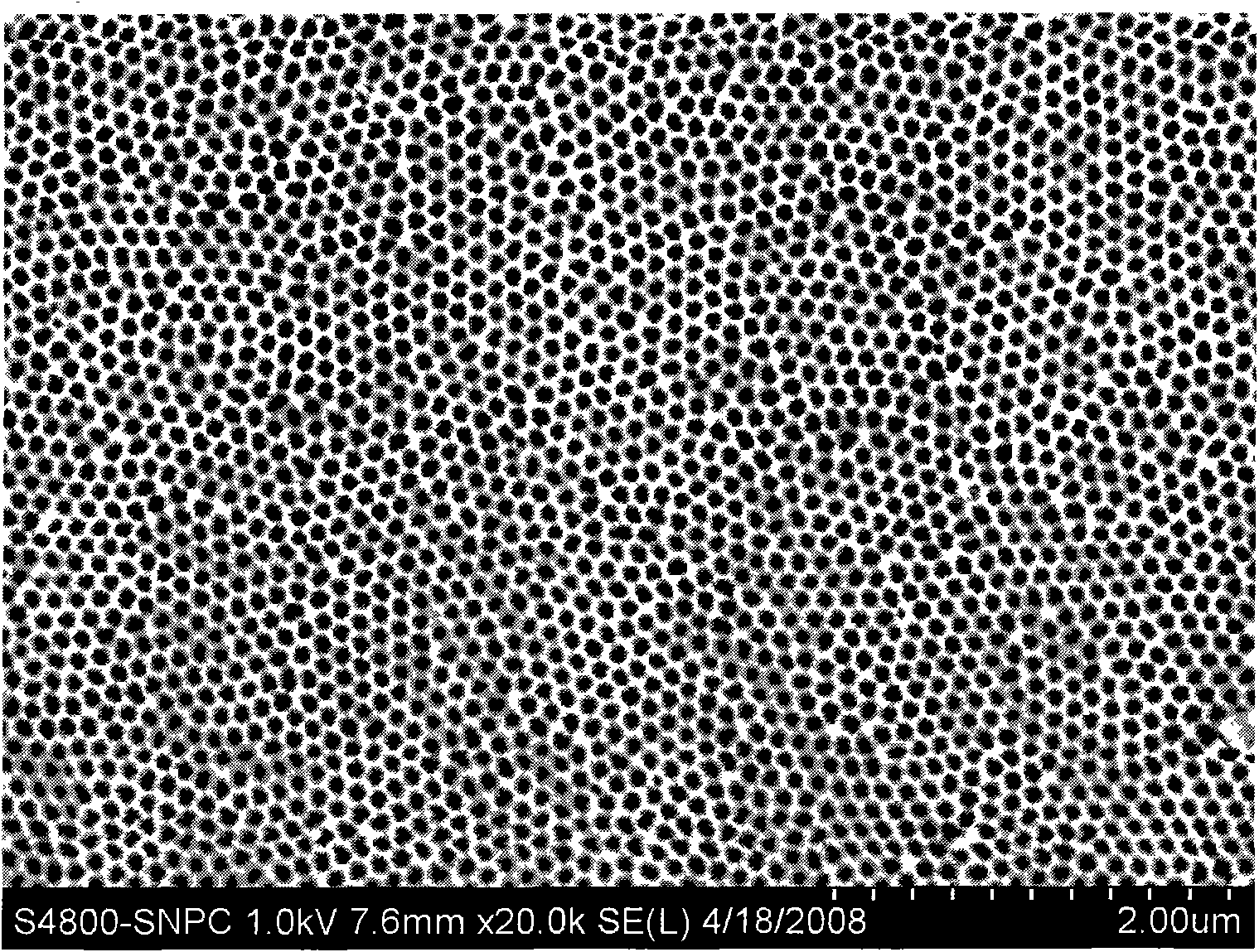

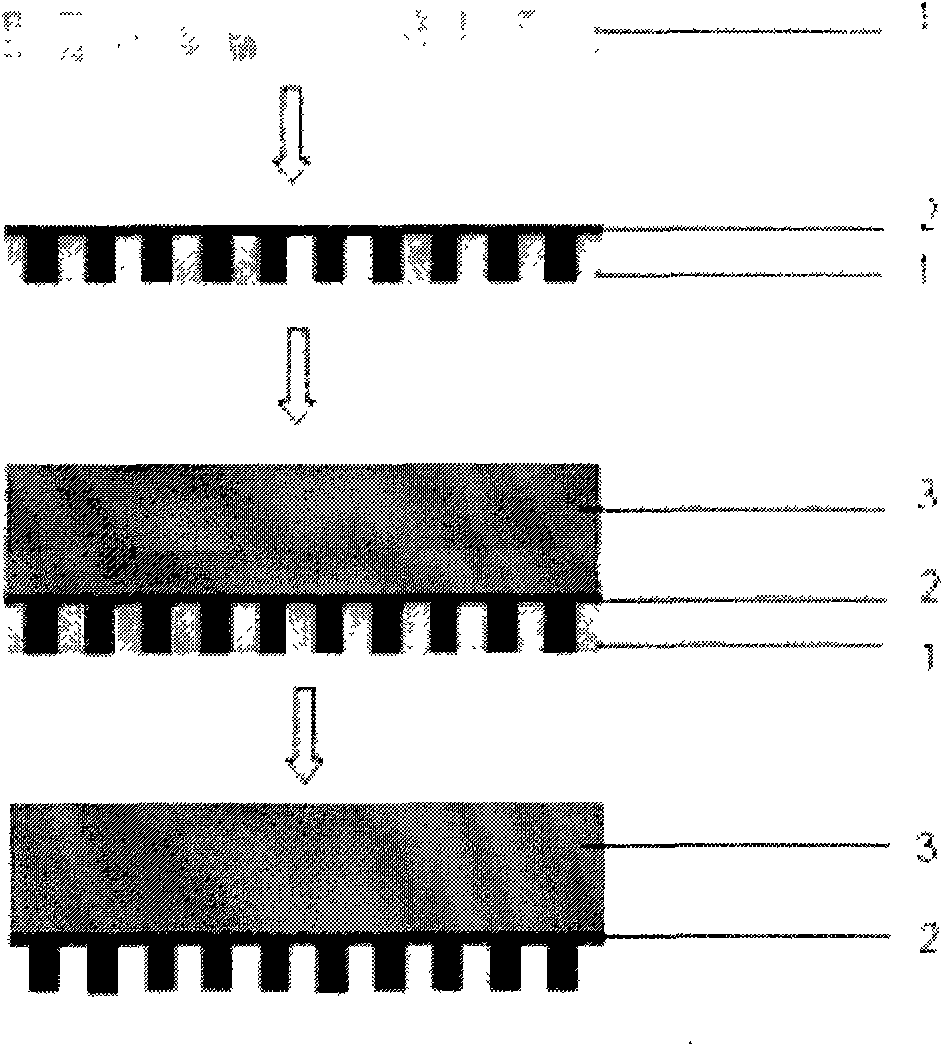

[0022] 1. Porous anodized aluminum AAO is used, with a pore size of 100nm.

[0023] 2. Deposition of a layer of CF on AAO by gas-phase CVD 3 -(CF 2 ) 7 -(CH 2 ) 2 -SiCl 3 Antisticking agent.

[0024] 3. Mix the PDMS prepolymer and curing agent at a ratio of 10:1, then add 60% by weight of toluene, stir evenly with a glass rod, and degas under vacuum for 30 minutes to obtain a polymer.

[0025] 4. Coat the mixed polymer on the specific surface of AAO at 1000rmp / 30min, and degas for 5min.

[0026] 5. Then pour the degassed PDMS on the above polymer surface.

[0027] 6. Thermal curing at 100°C for 1 hour in vacuum.

[0028] 7. The polymer is peeled off from the AAO to obtain the replicated nanoimprint soft template.

Embodiment 2

[0030] 1. Porous anodized aluminum AAO is used, with a pore size of 100nm.

[0031] 2. Deposition of a layer of CF on AAO by gas-phase CVD 3 -(CF 2 ) 7 -(CH 2 ) 2 -SiCl 3 Antisticking agent.

[0032] 3. Mix 3.4g of VDT-731, 50μg of SIP6381.1, and 100μg of FlUKA87927, degas in vacuum for 5min, then add 1g of HMS-301 and mix well.

[0033] 4. Spin coat the above mixture at 1000rmp / 30min, and then cure at 60°C for 30min. A layer of h-PDMS polymer was obtained.

[0034] 5. Then pour the degassed PDMS on the above polymer surface.

[0035] 6. Thermal curing at 65°C in vacuum for 24 hours.

[0036] 7. The polymer is peeled off from the AAO to obtain the replicated nanoimprint soft template.

Embodiment 3

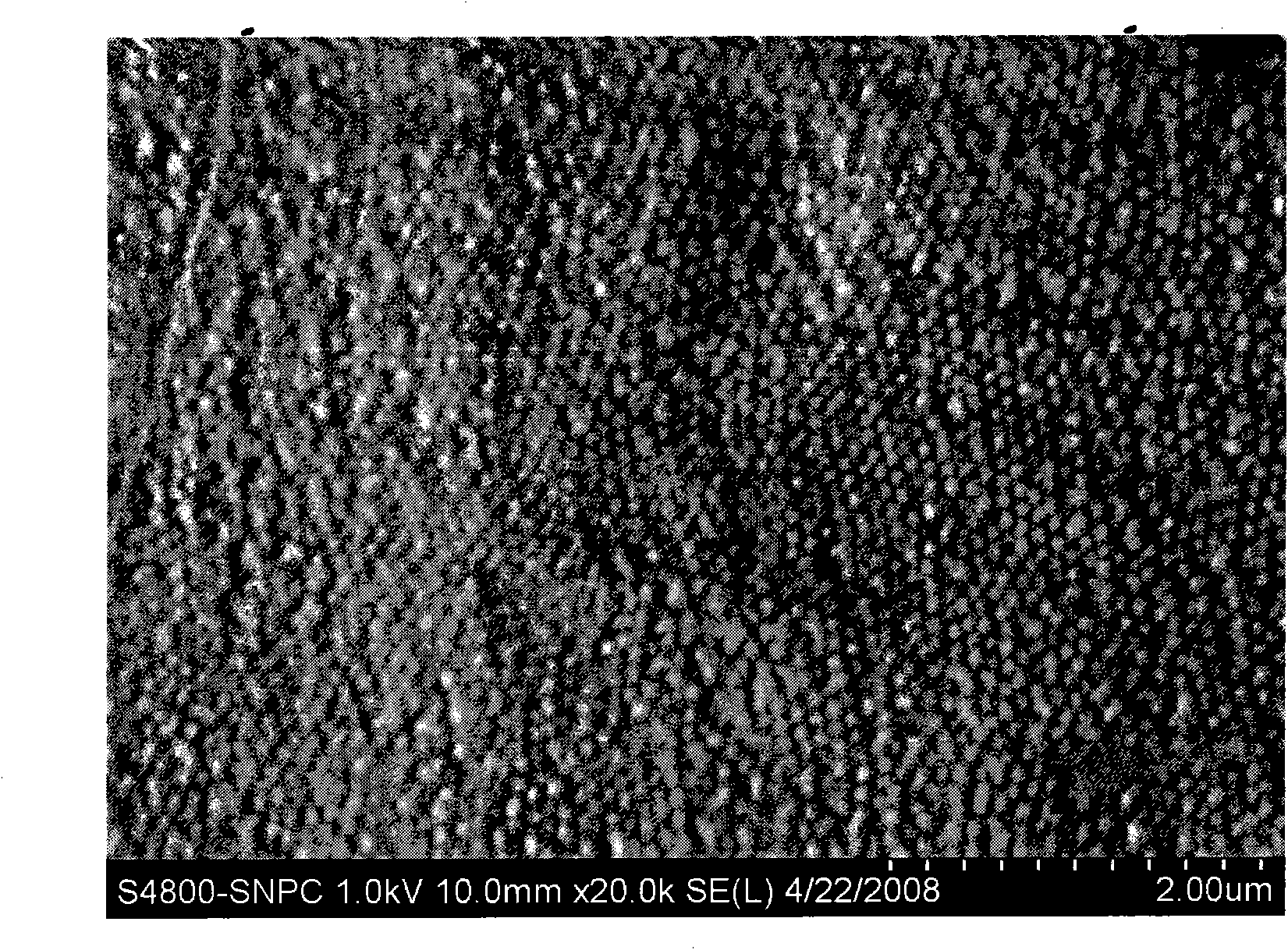

[0038] 1. Spin-coat PMMA on the Si wafer and heat at 180°C for 20min.

[0039] 2. Put the anti-adhesive treated AAO on the PMMA surface.

[0040] 3. Apply pressure on the AAO, the experimental parameters are 180°C / 50Torr / 5min.

[0041] 4. Release the mold to obtain a columnar structure on PMMA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com