Method for magnetizing magnetic component of permanent magnetic crane

A technology of magnetic components and magnetization methods, applied to magnetic objects, electrical components, circuits, etc., can solve the problem of permanent magnet cranes being unable to be assembled, and achieve the effect of easy assembly, prevention of safety accidents, and mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

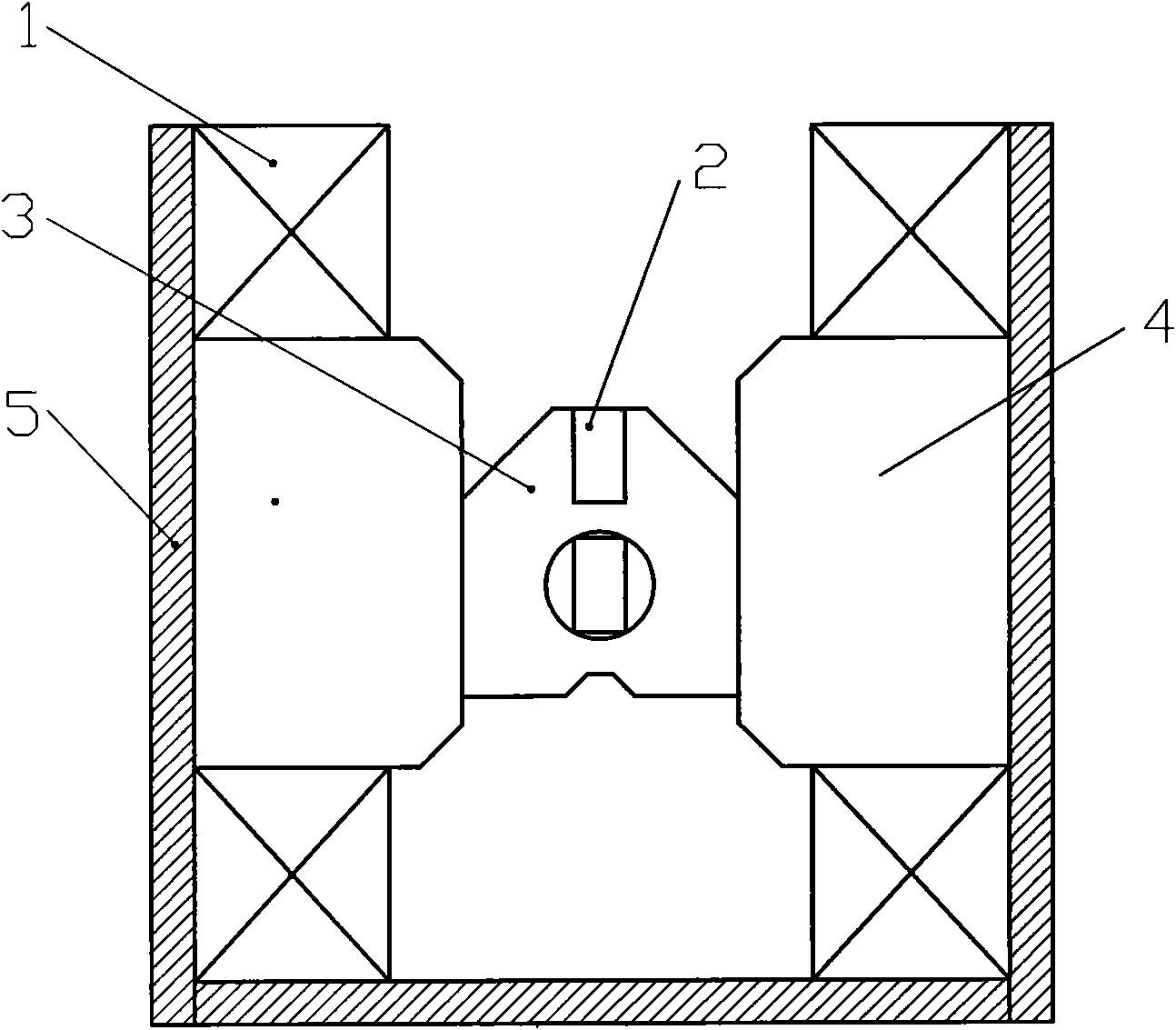

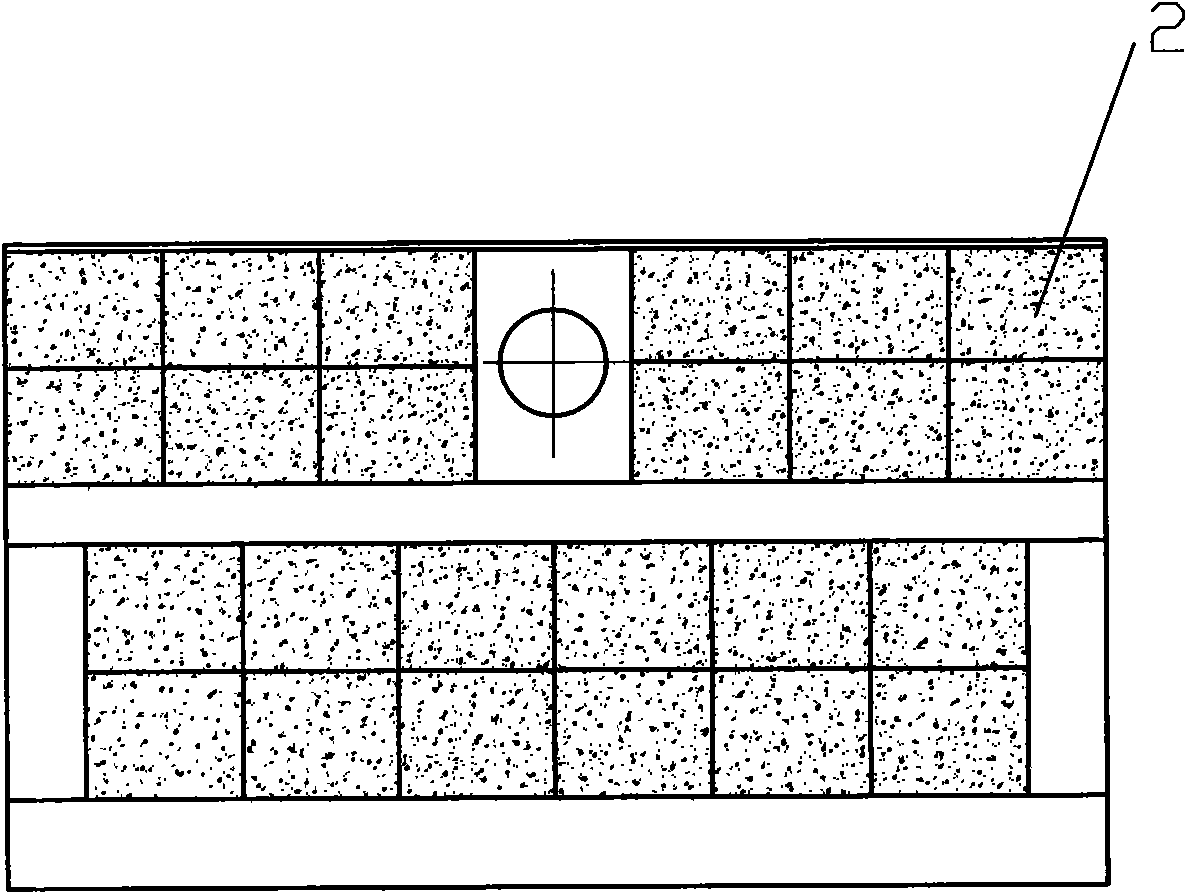

[0011] figure 1 , figure 2 Among them, 1 coil, 2 permanent magnet material mainly composed of neodymium iron boron (NdFeB), 3 crane, 4 pole head, 5 magnetic circuit iron plate.

[0012] A magnetizing method for a magnetic component of a permanent magnet crane, the method steps: the surface of the permanent magnet material 2 is glued, bonded together to form a component, put it into the crane 3, and cover the box cover.

[0013] After the installation is completed, it is magnetized, and the crane 3 is placed in the middle of the pole head 4, and the pole head 4 surrounds a coil 1, and a magnetic circuit iron plate 5 is arranged outside the coil 1.

[0014] During magnetization, when the current of the magnetization coil is 300A, a magnetic field of 30000GS is generated, which saturates the magnetization of the permanent magnet material 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com