Three-dimensional structure TM010-lambda/4 millimeter wave resonator based on silicon technology

A technology of three-dimensional structure and resonator, which is applied in the direction of resonators, waveguide devices, networks using active components, etc., can solve the problems that cannot meet the application requirements, and the power output of radio frequency oscillators is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

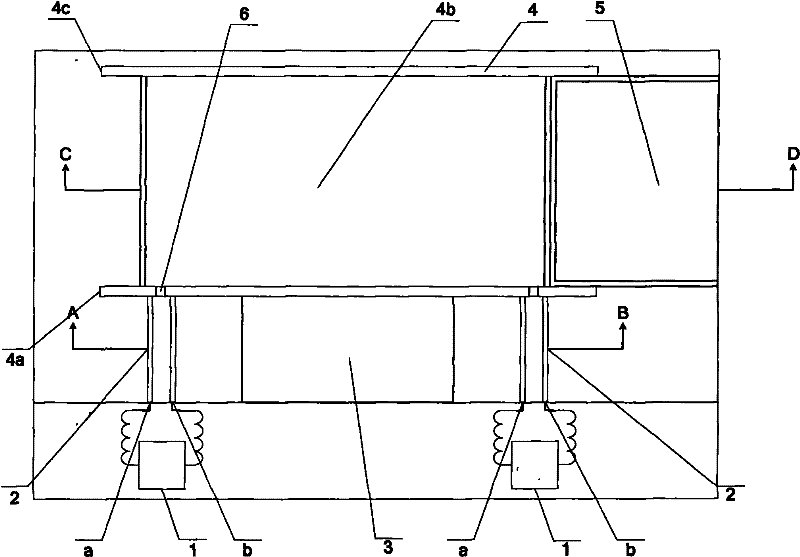

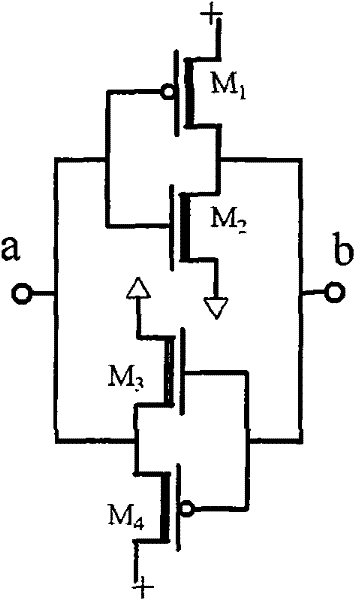

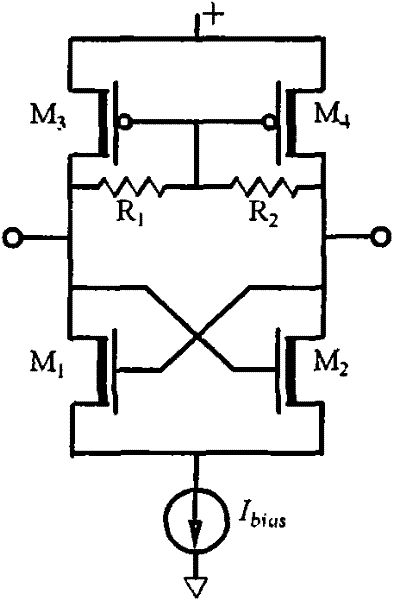

[0018] Such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the present invention consists of more than two active circuits 1 on the silicon substrate layer, λ / 4 resonators 2 corresponding to the number of active circuits 1 on the packaging layer, metal cylinders 3, and those working in the TM010 mode include the first A cylindrical waveguide resonator 4 composed of a conductive metal plate 4a, a cylindrical waveguide 4b and a second conductive metal plate 4c, and a rectangular waveguide 5 for power output; the two output ends a and b of each active circuit 1 correspond to The two open-circuit ends of the λ / 4 resonator 2 are connected at the junction of the silicon substrate layer and the packaging layer, and the two short-circuit ends of each λ / 4 resonator 2 are connected to the cylindrical waveguide resonator 4 on the first conductive metal plate 4a The upper connection realizes energy coupling through the slot 6 on the first conductive metal plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com