Laser soldering device

A technology of laser welding and laser beam, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of reduced operating efficiency, excessive welding time, and inability to heat the rod-shaped terminal 5a

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

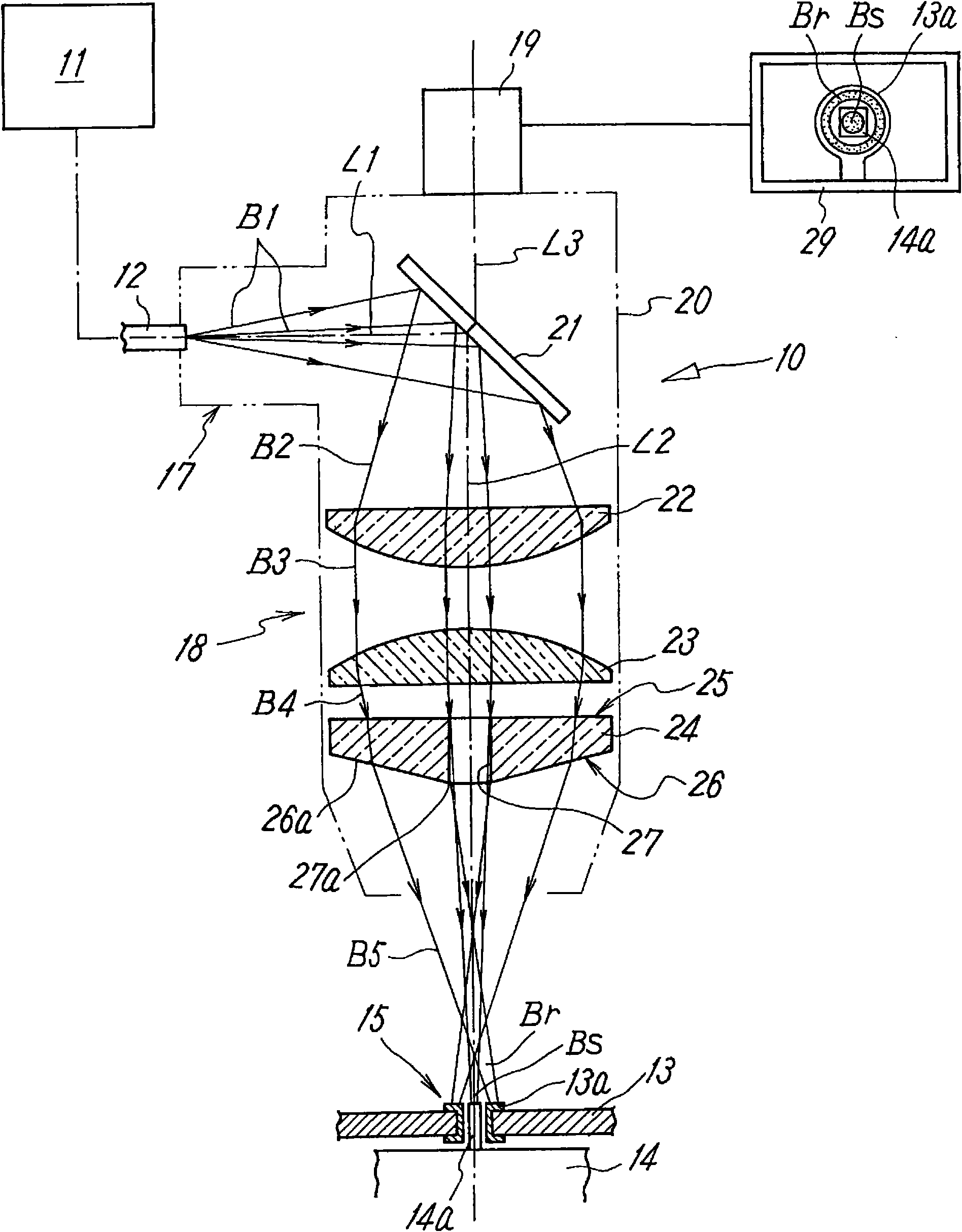

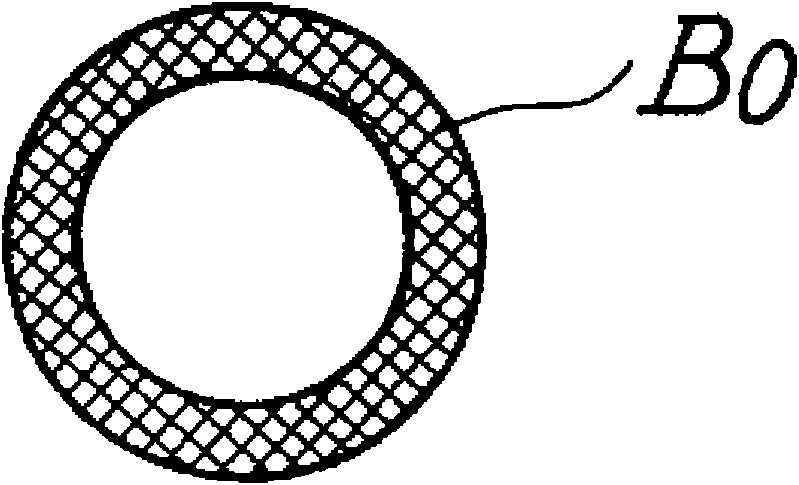

[0027] figure 1 It is a figure which schematically shows 1st Embodiment of the laser welding apparatus of this invention. In this figure, reference numeral "10" denotes a welder head provided on a multi-joint arm of a welding robot not shown; reference numeral "11" denotes a laser oscillator for outputting a laser beam B1; appended Reference numeral "12" denotes an optical fiber for guiding the laser beam B1 output from the laser oscillator 11 to the welder head 10. In addition, reference numeral “ 13 ” denotes a substrate provided with a printed circuit; and reference numeral “ 14 ” denotes electronic components soldered on this substrate 13 . Soldering is performed in a state where the rod-shaped terminal 14 a of the electronic component 14 is inserted into the ring-shaped terminal 13 a on the substrate 13 . Therefore, these ring-shaped terminal 13 a and rod-shaped terminal 14 a constitute a welding target 15 .

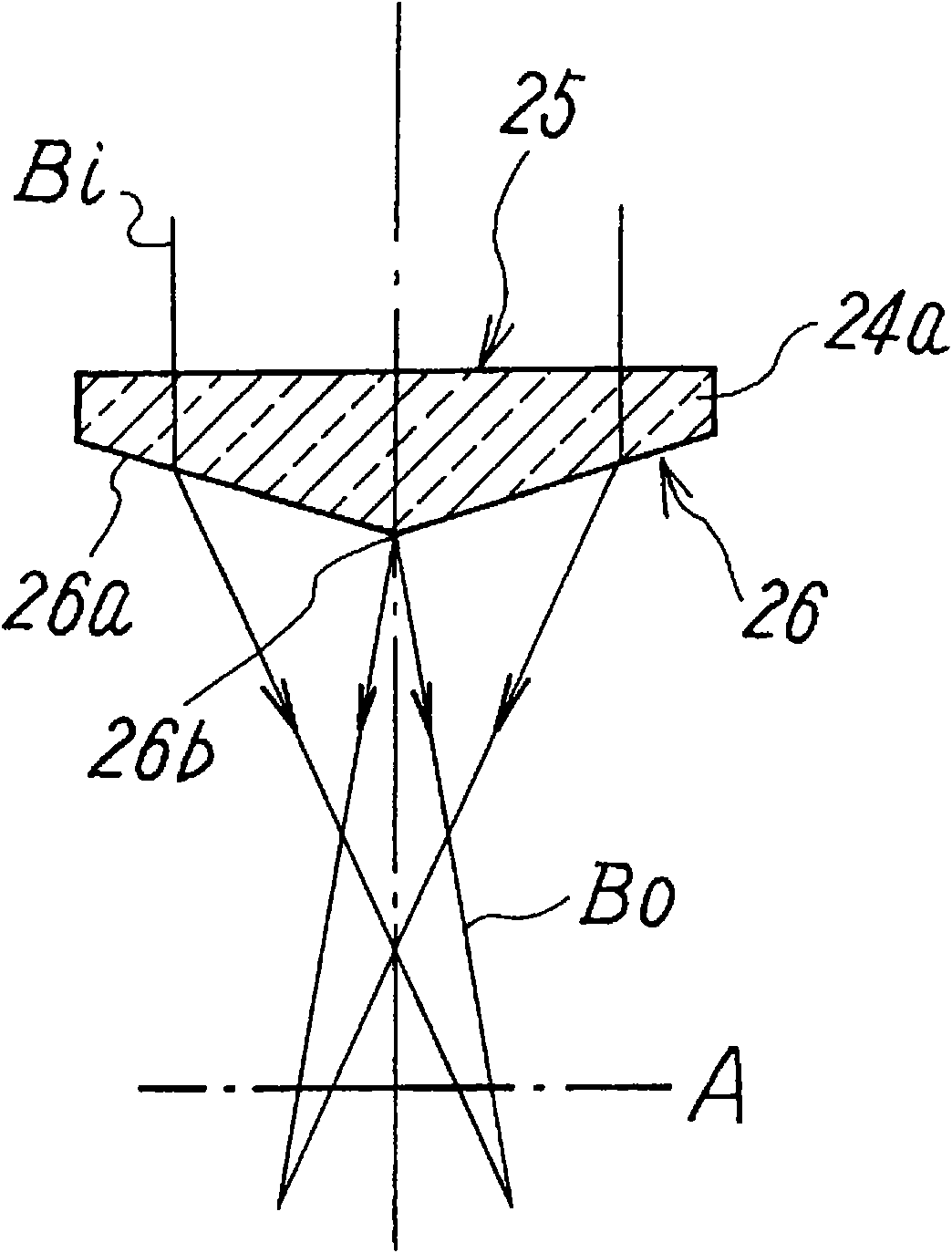

[0028] The welder head 10 has: an incident part 17, into w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com