Multi-stage precooling cryoablation method and device

A refrigeration device and a pre-cooling technology, applied to the device implementing the above method, in the field of multi-stage pre-cooling cryoablation, can solve the problems of limited rewarming effect, not very large refrigeration power, blockage, etc., achieving convenient treatment and improving refrigeration efficiency and the effect of cooling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the purpose, features and advantages of the present invention, preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

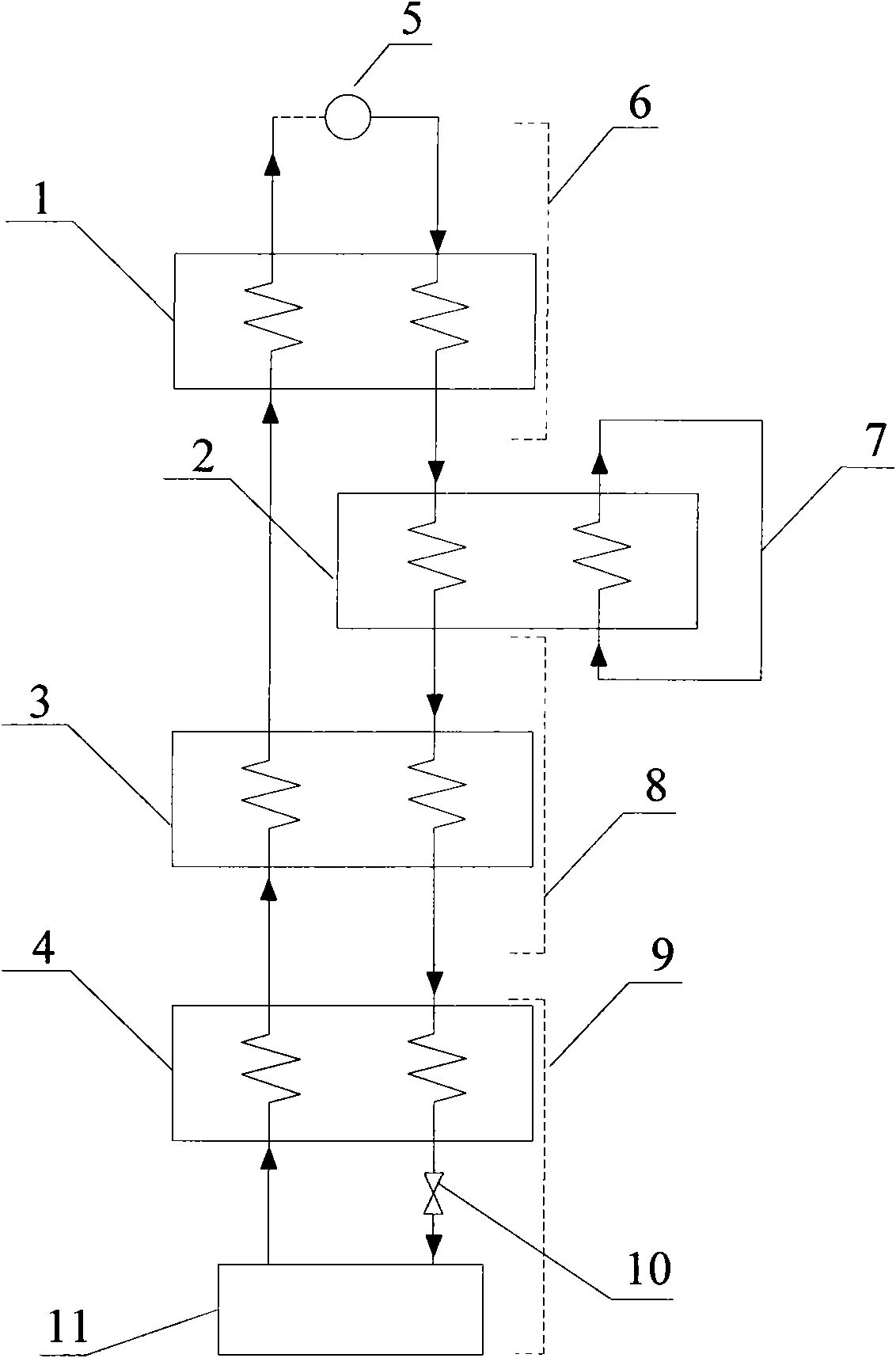

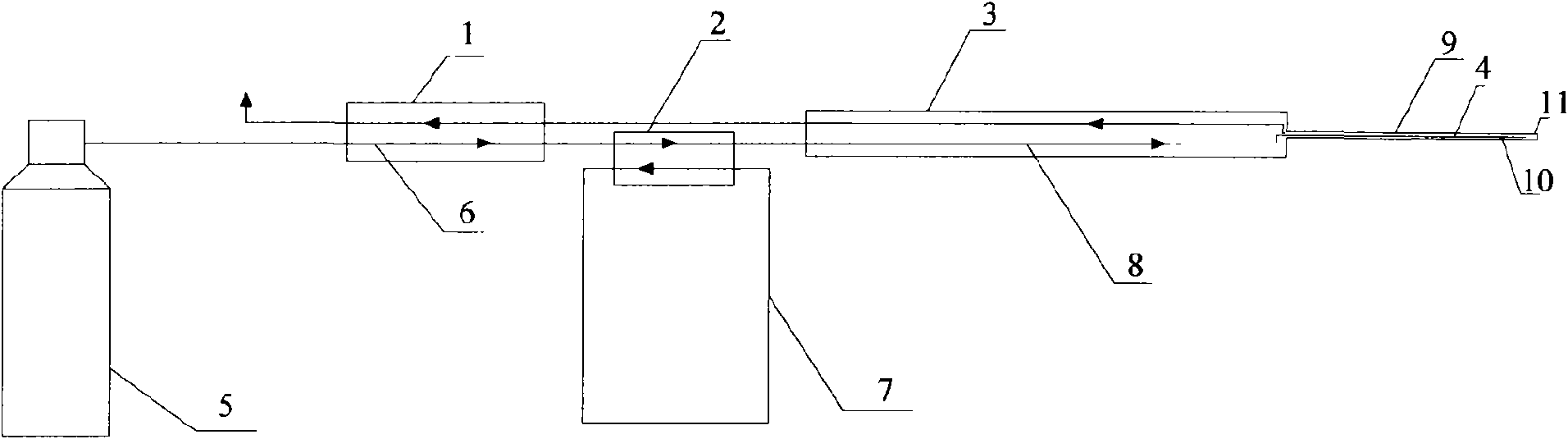

[0022] Such as Figure 1-2 As shown, the multi-stage precooling cryoablation device in a preferred embodiment of the present invention consists of the first stage precooling heat exchanger 1, the second stage precooling heat exchanger 2, the third stage precooling heat exchanger 3, the second stage 4-stage pre-cooling heat exchanger 4, pressure source 5, intake pipeline 6, refrigeration equipment 7, delivery pipeline and handle 8, freezing probe or catheter 9, expansion device 10 and treatment end 11, wherein: pressure source 5 It is a gas cylinder filled with 0.1MPa~50MPa pressure refrigerant, and the first, second, third, and fourth-stage pre-cooling heat exchangers 1, 2, 3, and 4 are self-made tube heat exchangers or plate heat exchangers; refrigerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com